Film cooling roller

A film cooling and roller technology, applied in the field of cooling mechanism, can solve the problems affecting film production quality and production efficiency, uneven cooling of the roller, uneven film, etc., to improve the cooling effect of heat dissipation, the cooling effect is good, and the cooling is uniform. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

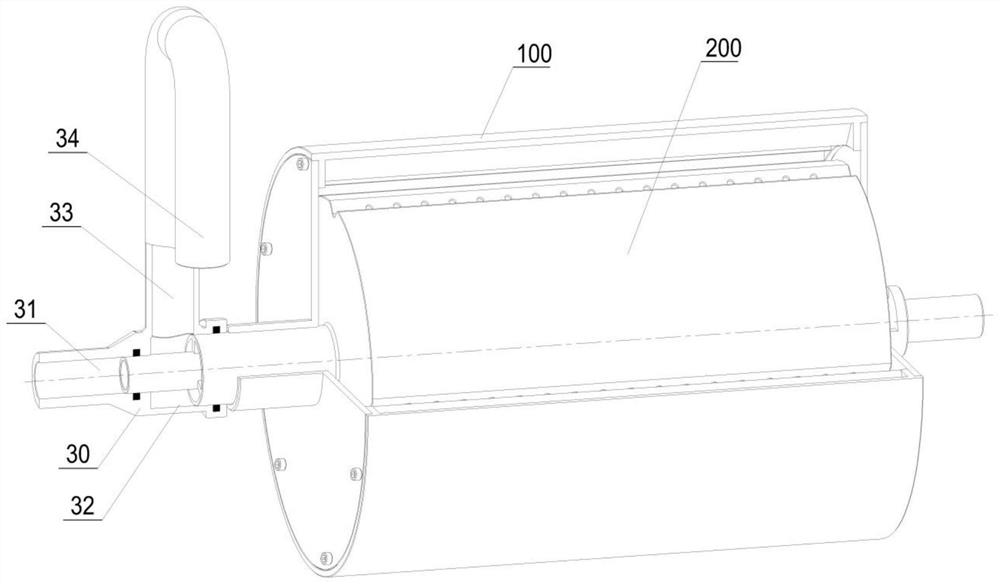

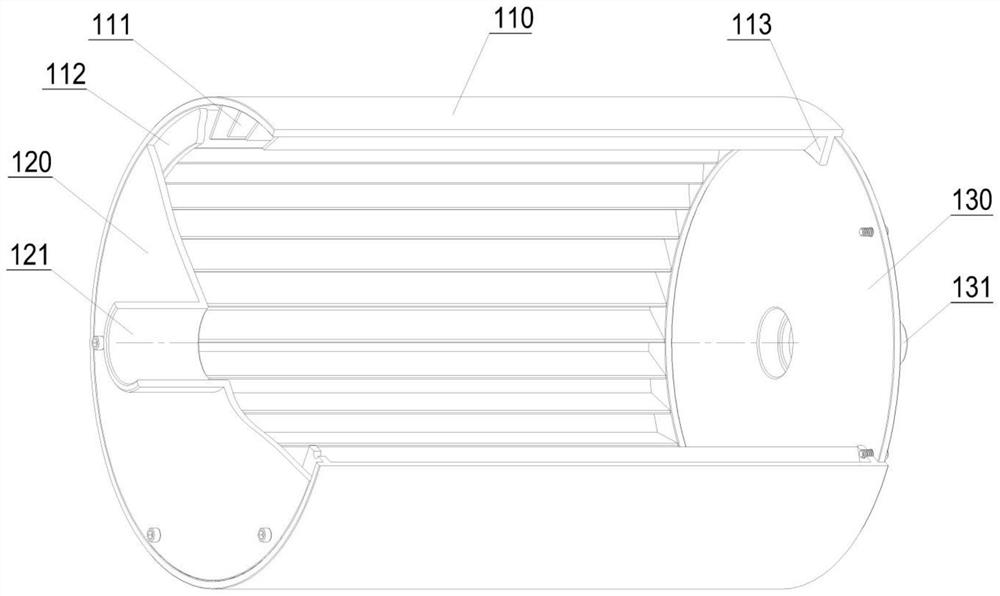

[0026] Such as Figure 1-Figure 4 As shown, a film cooling roller is disclosed, including a roller 100, a water distribution rotor 200 and a movable joint 30; A heat sink 111 is provided, and the water distribution rotor 200 is coaxially arranged in the roller 100;

[0027] Such as figure 1 As shown, the movable joint 30 includes a water inlet port 31 and a drain port 32; the movable joint 30 is rotationally connected with the left end of the water distribution rotor 200,

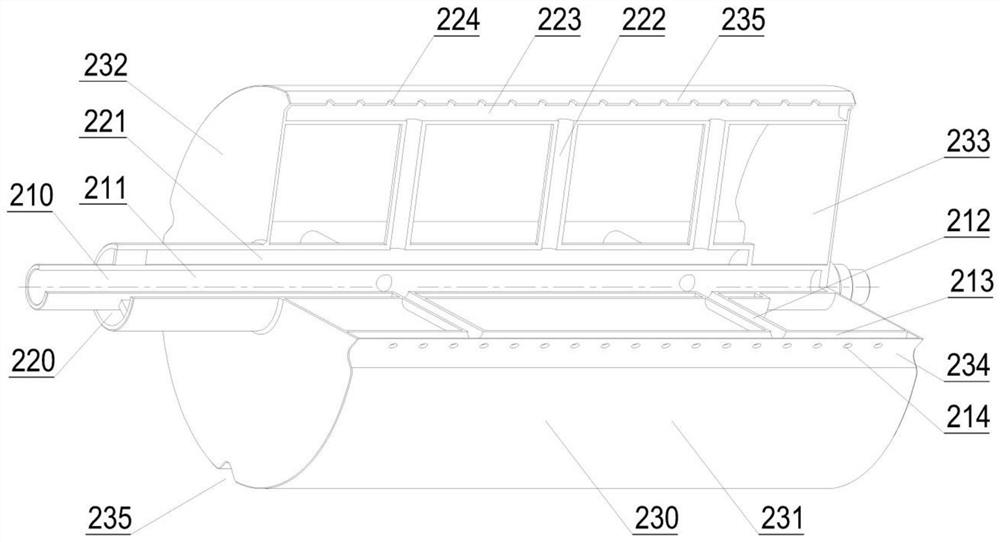

[0028] Such as image 3 As shown, the water distribution rotor 200 includes a water inlet channel 210, a drainage channel 220 and a rotor body 230;

[0029] The water inlet channel 210 is composed of the water inlet main pipe 211, the water inlet branch pipe 212, the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com