Variable-duct tailstock type high-speed unmanned aerial vehicle and working method thereof

A technology of unmanned aerial vehicle and tail seat, which is applied in the field of unmanned aerial vehicles, can solve the problems of small parking area and insufficient stability, and achieve the effects of strong environmental adaptability, improved flight efficiency and applicability, and large combat radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

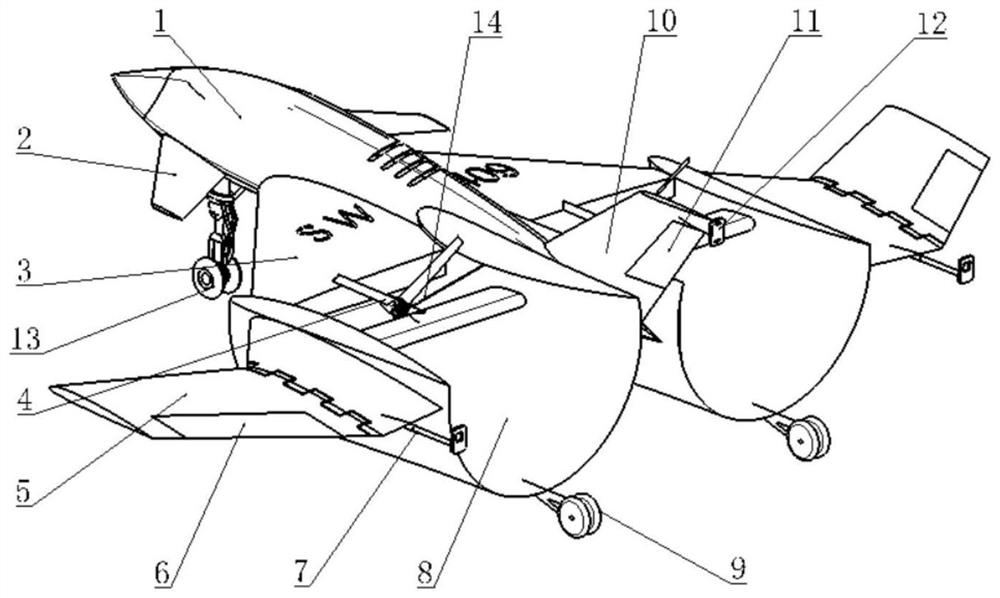

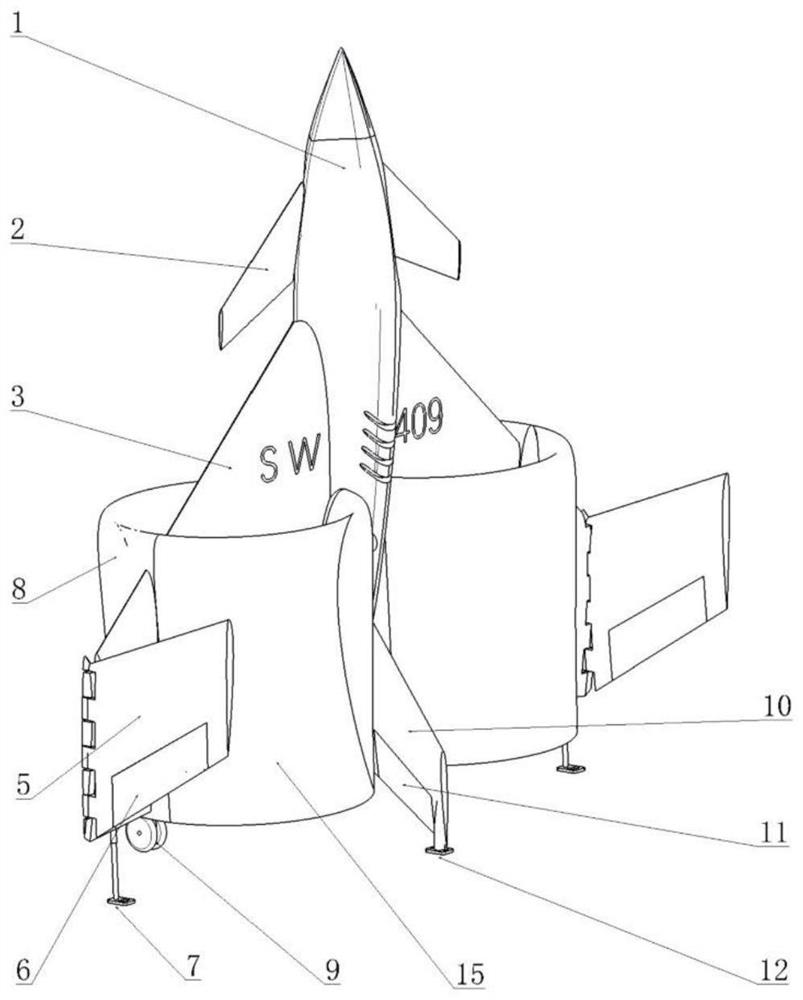

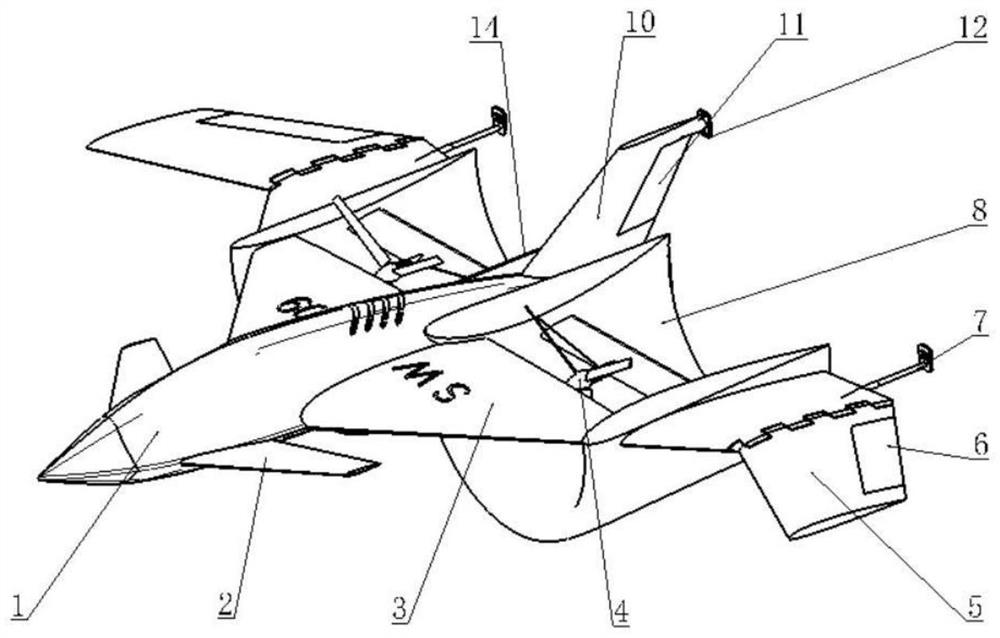

[0032] Such as Figure 1~4 As shown, a kind of variable duct tail seat type high-speed UAV of the present invention comprises: fuselage 1, canard 2, swept wing 3, rotor system 4, forward swept wing 5, aileron 6, wing vertical Landing gear 7, lower half duct 8, rear landing gear 9, vertical tail 10, rudder 11, vertical tail vertical landing gear 12, front landing gear 13, duct telescopic mechanism 14, upper half duct 15.

[0033] The main wing, namely the swept wing 3, is installed in the middle part of the fuselage 1, and the front landing gear 13 is positioned at the lower part of the fuselage 1 front. Reduce the resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com