Corrosion-resistant fixing screw capable of improving three-dimensional splicing strength of plates and using method

A technology of splicing strength and fixing screws, which is applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve the problems of narrow screw heads, poor force bearing capacity of plate parts, and poor anti-loosening performance, so as to improve efficiency and ingenious structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

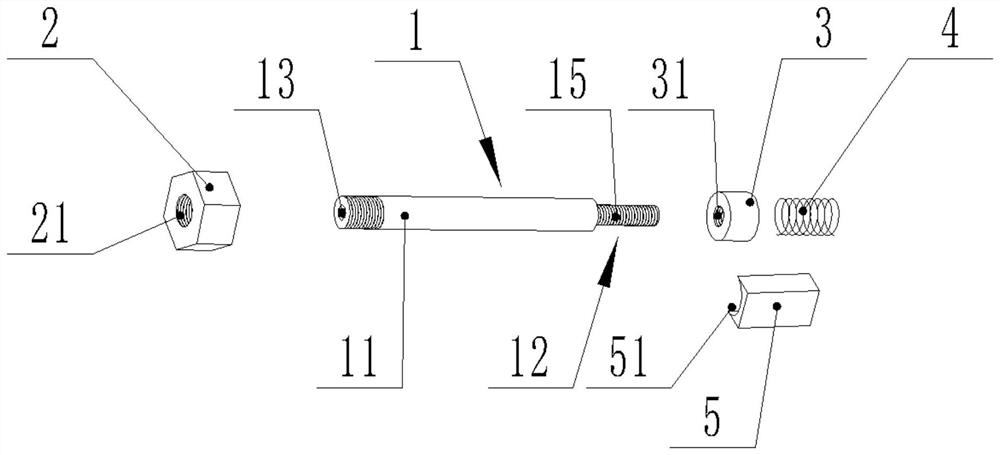

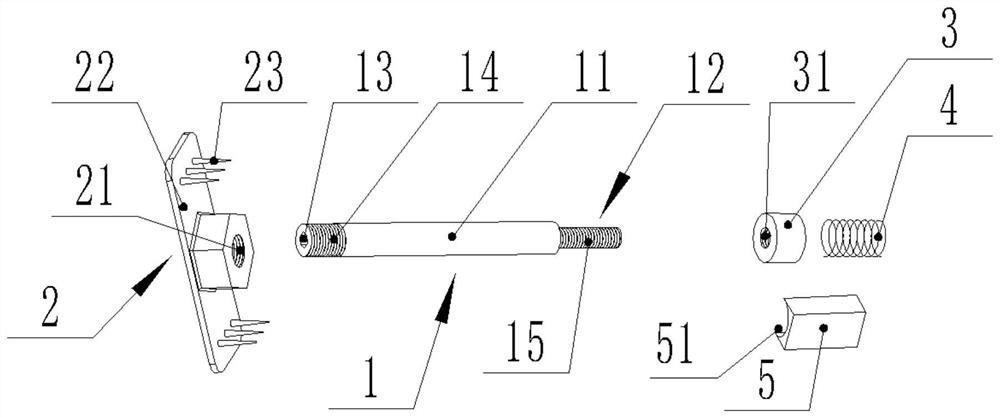

[0034] to combine figure 1The shown corrosion-resistant fixing screw for improving the three-dimensional splicing strength of plate parts includes a screw 1, and the material of the screw 1 is austenitic stainless steel, and the whole body is carburized. Moreover, the screw 1 includes a first shaft segment 11 and a second shaft segment 12, the second shaft segment 12 is arranged at one end of the first shaft segment 11, the diameter of the second shaft segment 12 is smaller than that of the first shaft segment 11, The end of the first shaft section 11 away from the second shaft section 12 is provided with a screwdriver recess 13, the end of the first shaft section 11 near the screwdriver recess 13 is provided with a first thread 14, and the second shaft section 12 is provided with a second Two threads 15, and the first thread 14 and the second thread 15 have opposite screw directions. At the same time, it also includes a base body 2 , the base body 2 is a hexagonal nut, and a...

Embodiment 2

[0038] combine figure 2 The shown corrosion-resistant fixing screw for improving the three-dimensional splicing strength of board parts, on the basis of Embodiment 1, an extension plate 22 is provided at the bottom of the seat body 2, and a group of nails 23 are provided on the extension board 22 . ,

[0039] When the connecting plate is a wooden board, the nail portion of the extension board 22 is nailed into the wooden board while the base body 2 is buried in the wooden board, so as to improve the reliability of splicing.

Embodiment 3

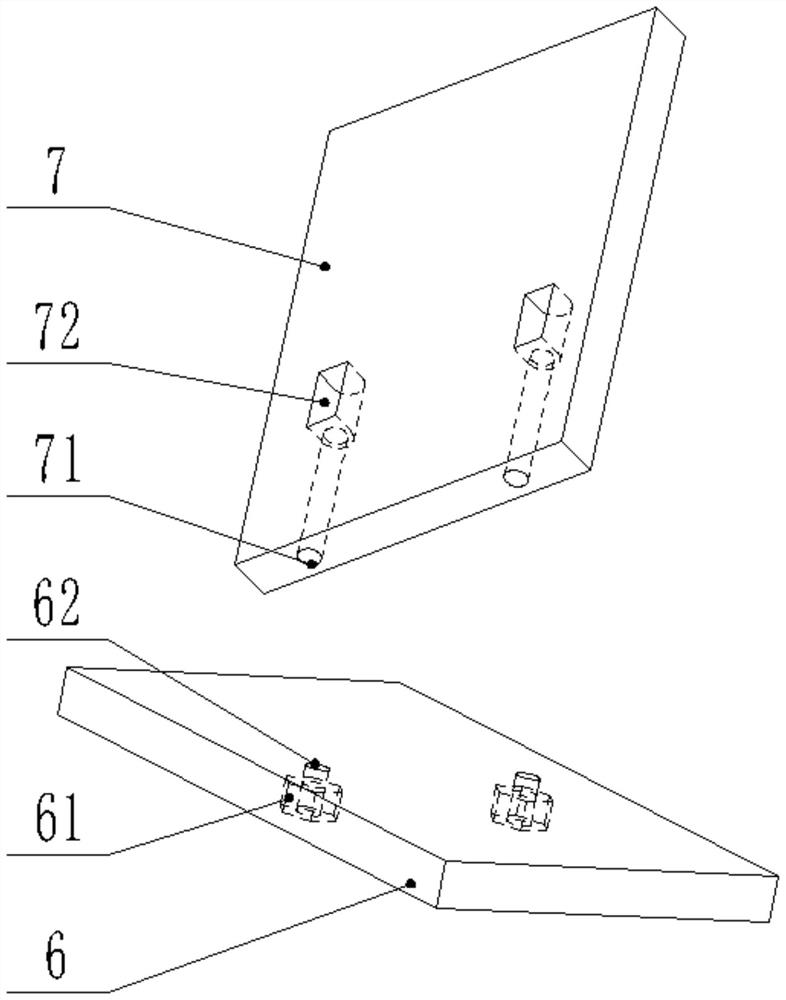

[0041] combine Figure 3-6 The method for using a corrosion-resistant fixing screw to improve the three-dimensional splicing strength of the panels shown in Example 1 is shown, wherein the panel to be spliced includes a seat panel 6 and a riser 7, and the riser 7 needs to be spliced vertically on the seat On the plane of plate 6, the steps involved are as follows:

[0042] S1: Slot holes are provided on the seat plate 6 and the vertical plate 7, wherein a counterbore 61 and a through hole 62 are provided on the plane of the seat plate 6, the counterbore 61 is adapted to the contour of the seat body 2, and the through hole 62 is provided in In the projected area of counterbore 61; Wherein, offer shaft hole 71 on the side of riser 7, and set up bushing groove 72 on the plane of riser 7, described shaft hole 71 is adapted to first shaft segment 11, described The bushing groove 72 is adapted to the bushing 3, and the shaft hole 71 communicates with the bushing groove 72;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com