Vacuumizing exhaust equipment for low-light-level image intensifier production

A technology of low-light image intensifier and exhaust equipment, which is applied in the direction of electric tube/lamp exhaust, etc., can solve the problems of complicated operation and high labor intensity of staff, and achieve the effect of reducing labor intensity and meeting pressure requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

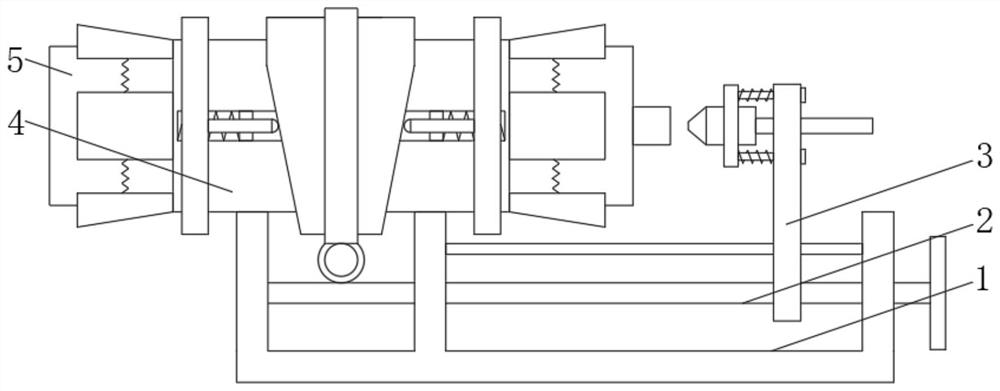

[0028] Embodiment one, by Figure 1-8 Provided, the present invention includes a mounting frame 1, a driving assembly 2 is installed inside the mounting frame 1, a vacuum assembly 3 is installed at one end of the driving assembly 2, a positioning assembly 4 is installed at the other end of the driving assembly 2, and the inside of the positioning assembly 4 A picture tube 5 is placed, and the positioning assembly 4 is connected with the installation frame 1;

[0029] The drive assembly 2 can drive the positioning assembly 4 to position and clamp the picture tube 5, and at the same time drive the vacuum assembly 3 to align with the picture tube 5, so that it is convenient for the staff to connect the vacuum assembly 3 and the picture tube 5, thereby improving the work efficiency of the staff .

Embodiment 2

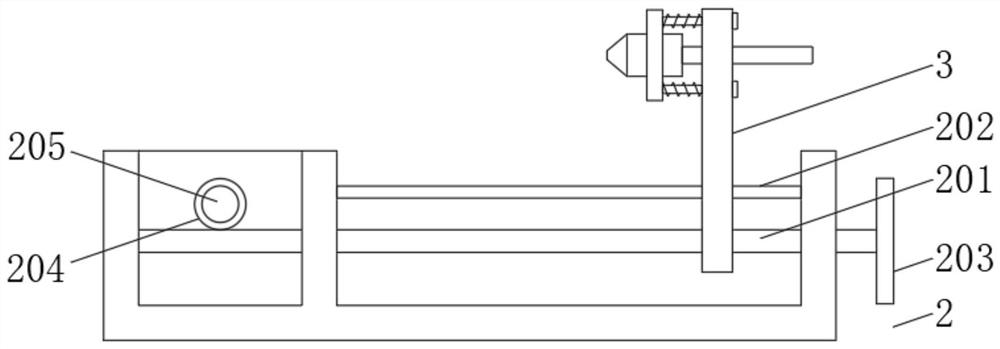

[0030] Embodiment 2, on the basis of Embodiment 1, the drive assembly 2 includes a drive worm 201 that is rotatably connected to the mounting frame 1, and a guide rod 202 connected to the mounting frame 1 is provided above the drive worm 201, and one end of the drive worm 201 is installed There is a rotating rod 203, the other end of the driving worm 201 is meshed with a driving worm gear 204, the driving worm gear 204 is installed on the driven worm 205, and the driven worm 205 is rotatably mounted on the mounting frame 1;

[0031] By rotating the rotating rod 203, the rotating rod 203 drives the driving worm 201 to rotate, and the driving worm 201 drives the vacuum assembly 3 to move through threads, making it gradually approach the picture tube 5, while the driving worm 201 drives the driving worm gear 204 to rotate by means of meshing , the driving worm gear 204 drives the coaxial driven worm 205 to rotate, and the driven worm 205 drives the positioning assembly 4 to clamp ...

Embodiment 3

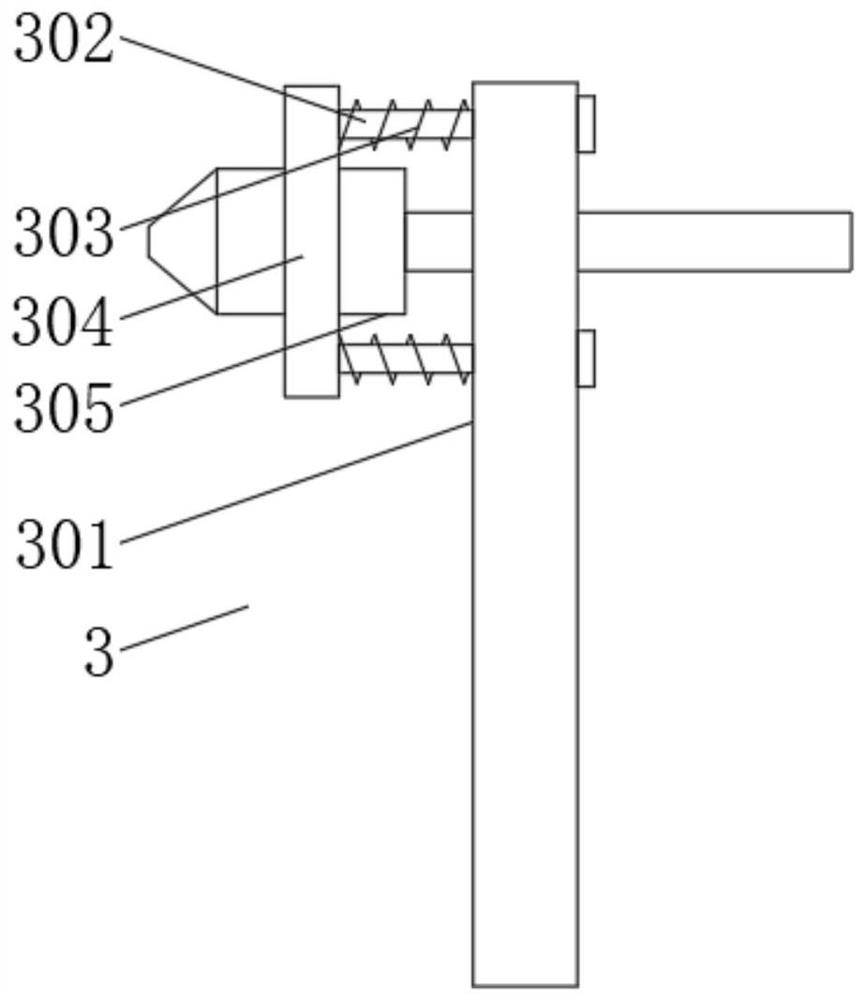

[0032] Embodiment 3, on the basis of Embodiment 1, the vacuum assembly 3 includes a moving plate 301 threadedly connected to the driving worm 201, a positioning rod 302 is inserted symmetrically on the moving plate 301, and a positioning spring is sleeved on the positioning rod 302 303, the positioning rod 302 is symmetrically installed on the mounting plate 304, the mounting plate 304 is equipped with a joint 305, the joint 305 is connected with an external vacuum pump, and the bottom of the moving plate 301 is respectively provided with a screw hole and a guide hole, and the screw hole is threaded with the driving worm 201 connection, the guide hole is socketed with the guide rod 202;

[0033] The active worm 201 drives the moving plate 301 to move, and the moving plate 301 drives the joint 305 on the mounting plate 304 to move close to the picture tube 5, so that it is convenient for the staff to connect the two together, and finally vacuumize through an external vacuum pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com