Safety maintenance damping protection system for tunnel

A protection system and safety technology, applied in tunnels, tunnel linings, springs/shock absorbers, etc., can solve problems such as easy loosening of joints, inconvenient use, safety issues, etc., and achieve improved shock absorption effect, convenient use, and safe use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

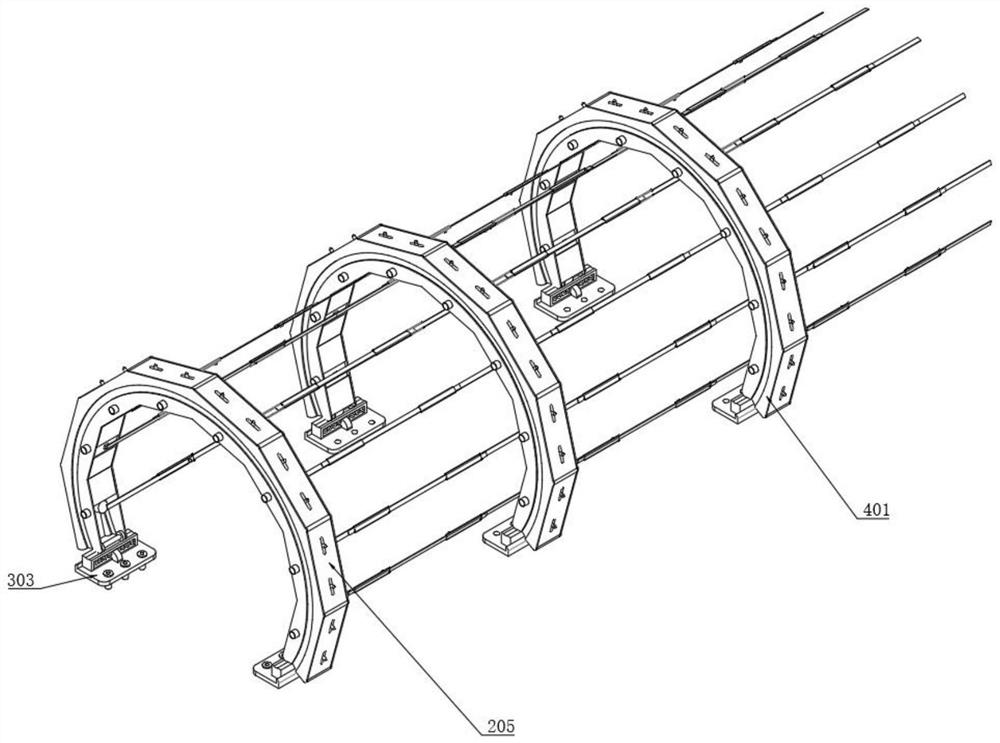

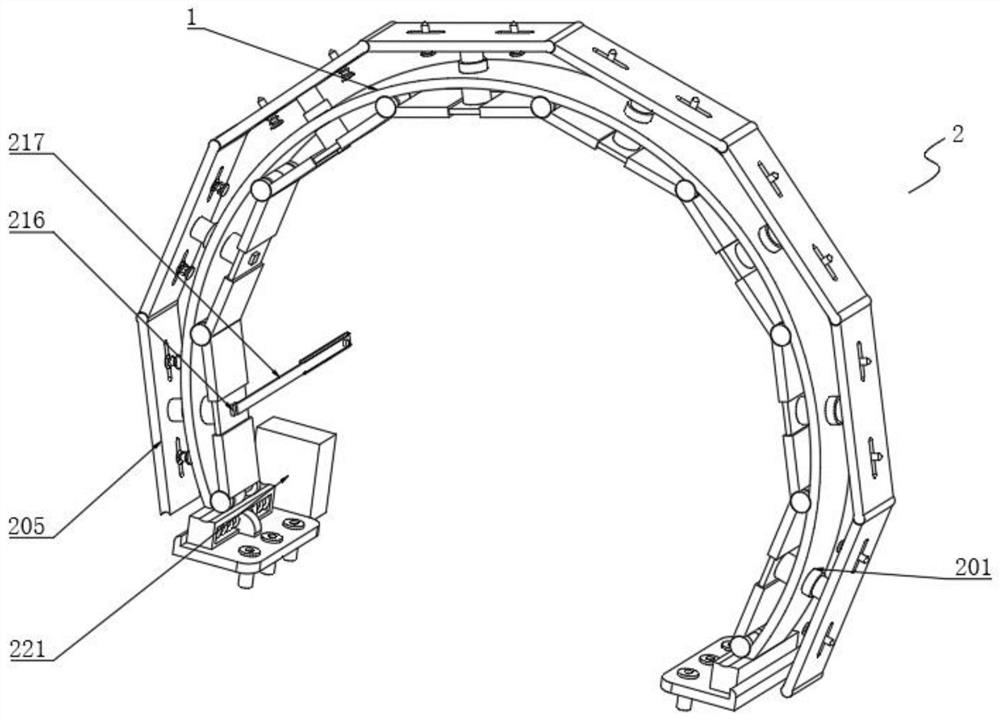

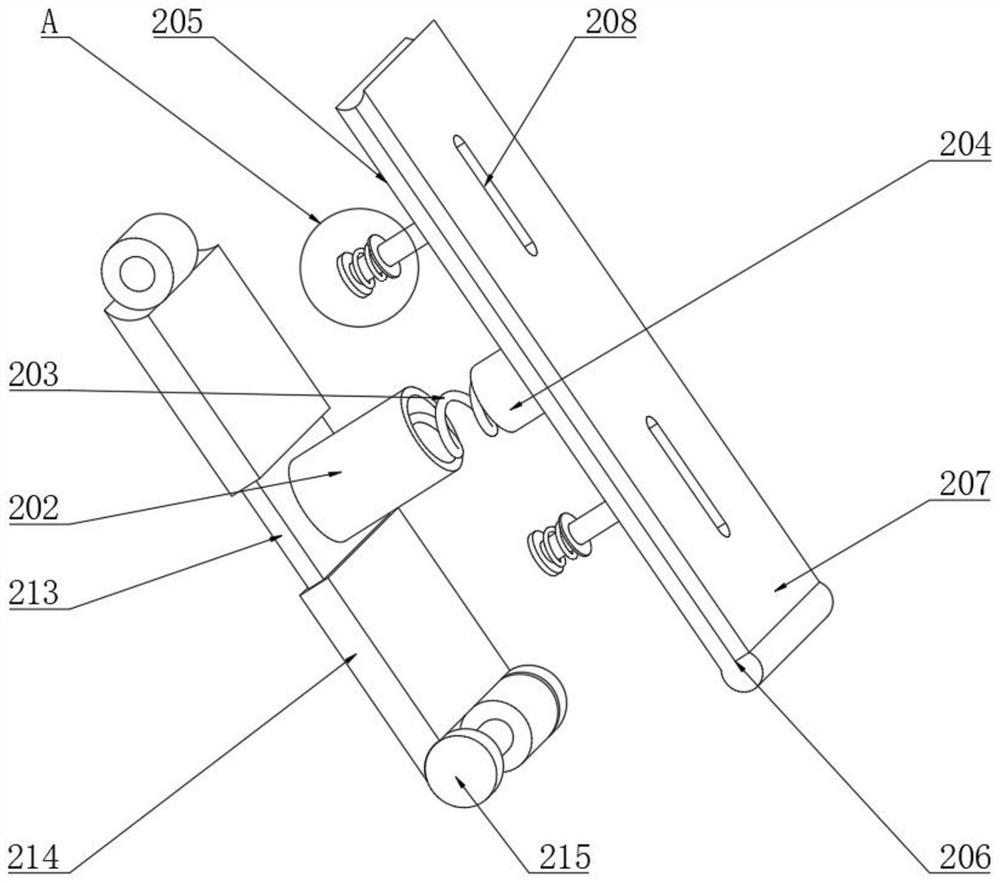

[0040] Example: such as Figure 1-5As shown, the present invention provides a technical solution for a safety maintenance shock absorption and protection system for tunnels, including a load-bearing frame 1, and a shock-absorption protection assembly 2 is arranged on the outside of the load-bearing frame 1, and the shock absorption protection assembly 2 includes a sliding hole 201, a buffer tube 202, longitudinal damping spring 203, buffer column 204, top plate 205, plate groove 206, rubber plate 207, guide port 208, positioning nail 209, fixed limit piece 210, movable limit ring 211, guide spring 212, spring plate 213 , connecting sleeve 214, connecting shaft 215, pressure sensor 216, induction plate 217, conduit 218, induction connecting rod 219, set screw 220 and control box 221;

[0041] A number of sliding holes 201 are equidistantly opened on the outside of the bearing frame 1. A buffer tube 202 is slidably installed inside the sliding hole 201. The outer sides of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com