PI test method for single valve in ESC assembly and electronic stability control system

A technology of electronic stability control and test method, applied in the field of vehicle safety, can solve the problems of long test cycle, affecting PI test efficiency, low test accuracy, etc., and achieve the effect of improving test efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

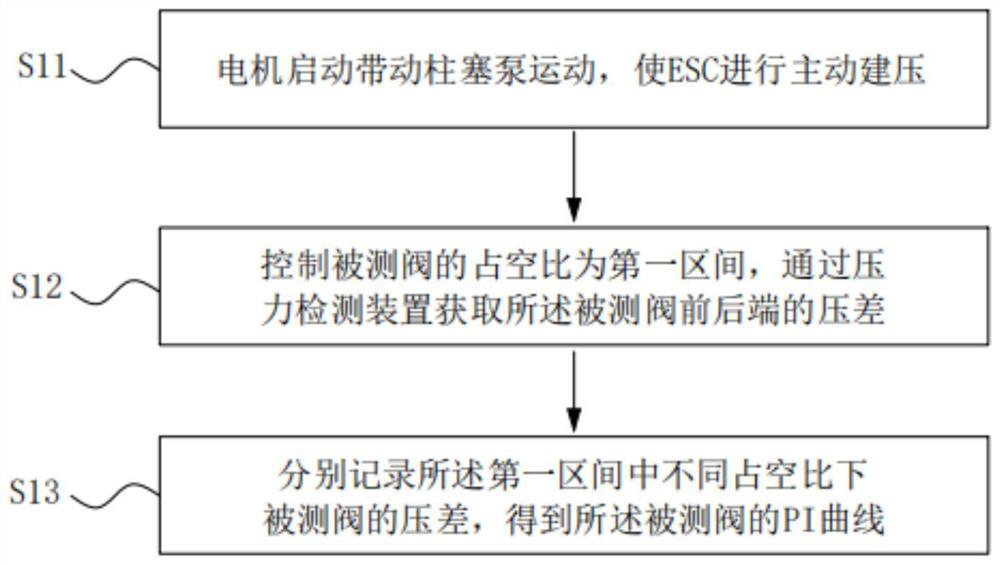

[0040] see figure 1 ,Such as figure 1 As shown, the single valve PI test method in the ESC assembly of the present invention comprises the following steps:

[0041] Step S11: The motor starts to drive the plunger pump to move, so that the ESC can actively build pressure.

[0042] Step S12: Control the duty ratio of the valve under test to be in the first interval, and obtain the pressure difference between the front and rear ends of the valve under test through the pressure detection device.

[0043] Step S13: respectively recording the pressure difference of the tested valve under different duty ratios in the first interval to obtain the PI curve of the tested valve.

[0044] In one embodiment, the method of the present invention further includes: before formally testing the PI curve, exhausting the ESC through a motor plunger pump to completely exhaust the gas in the test pipeline in the ESC.

[0045] In one embodiment, step S11: the motor starts to drive the plunger pump...

no. 2 example

[0065] The present invention also provides a method for performing any one of the above-mentioned implementation manners.

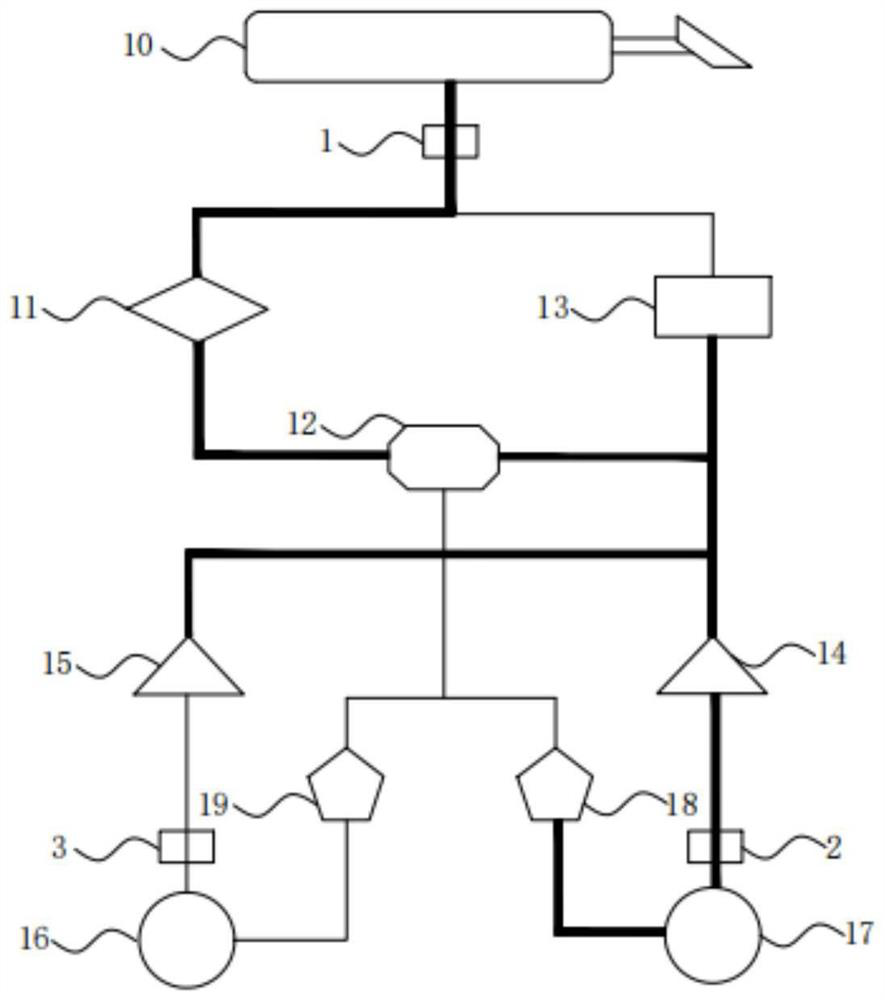

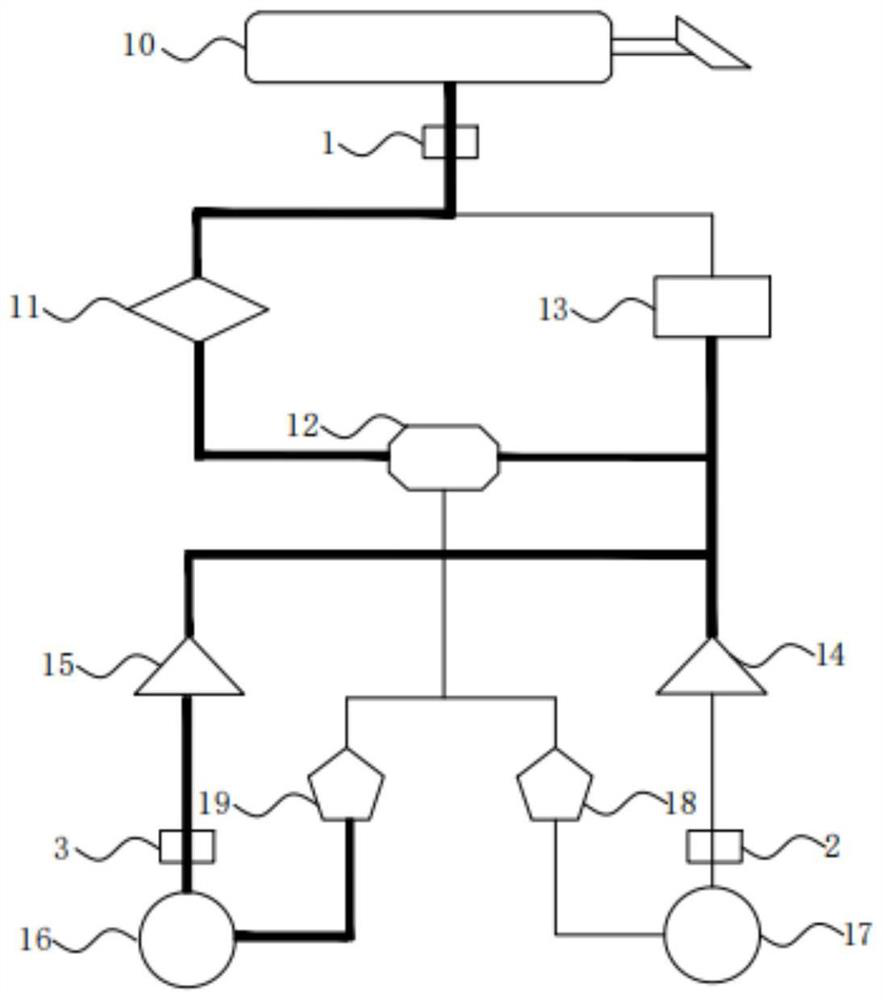

[0066] see Figure 4 ,Such as Figure 4 As shown, the electronic stability control system shown in the embodiment of the present invention includes: an oil supply valve 11, a motor plunger pump 12, a pressure regulating valve 13, a boost valve, a pressure relief valve and a pressure detection device. The boost valve at least includes: a first boost valve 15 and a second boost valve 14 . The pressure relief valve at least includes: a first pressure relief valve 19 and a second pressure relief valve 18 . The pressure detection device at least includes: a first pressure sensor 1 , a second pressure sensor 2 and a third pressure sensor 3 . The motor plunger pump 12 includes: a motor and a plunger pump. The motor and the plunger pump 2 are connected through complete mechanical contact. When the motor rotates, it drives the plunger pump to perform piston mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com