Vehicle cab sound quality evaluation method of PSO optimization delay operator model

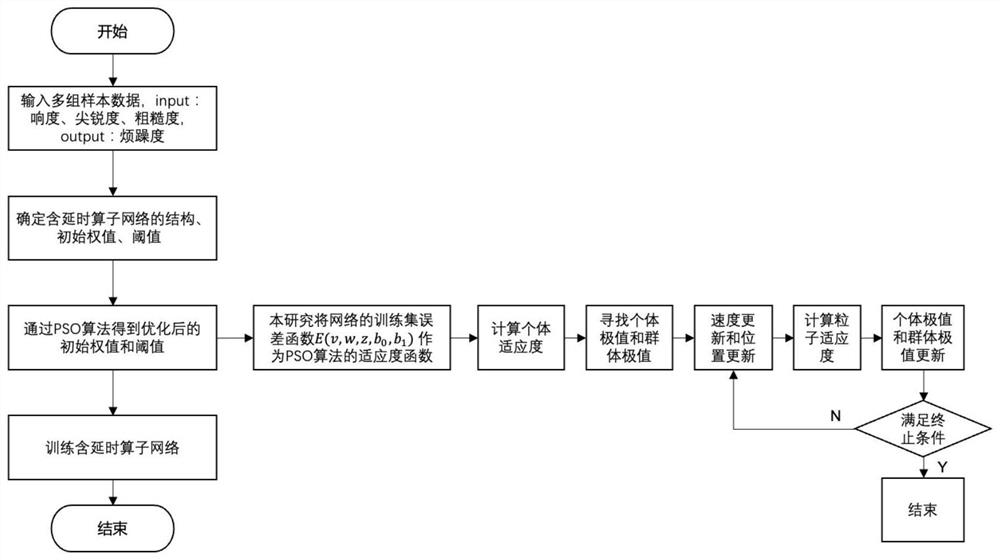

An evaluation method and sound quality technology, applied in multi-objective optimization, neural learning methods, design optimization/simulation, etc., can solve the problems that cannot be corrected, and the training takes a long time, so as to achieve short training time and suppress the occurrence of local minimum values , the effect of reducing training costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

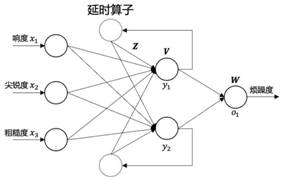

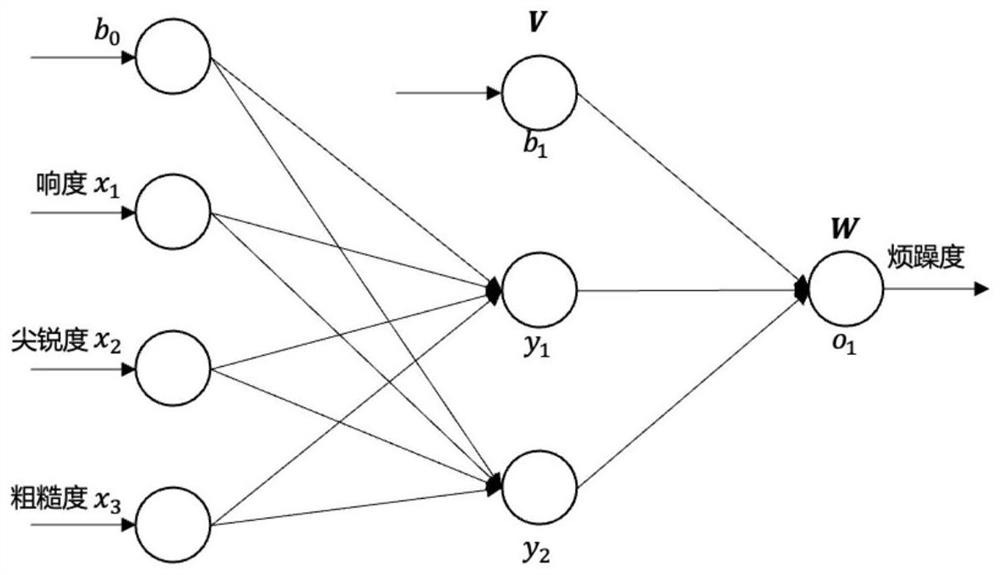

[0045] For the structure of the network model with delay operators, see figure 2 , let x, x 1 、x 2 、x 3 is the input layer node, x 1 、x 2 、x 3 Represent loudness, sharpness, and roughness respectively; y, y 1 、y 2 It is a hidden layer node, used for model training and calculation; o, o 1 is the output layer node, o 1 Represents the person's irritability to the sound; b 0 , b 1 is the threshold, omitted in the figure; k is the moment, w is the weight vector from the hidden layer to the output layer, and g is the transfer function of the output layer; then the node vector of the output layer is:

[0046] o(k)=g[wy(k)];

[0047] Let z be the weight vector from the hidden layer to the delay operator, d be the output vector of the delay operator, v be the weight vector from the input layer to the hidden layer, and f be the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com