Method for evaluating development degree of shale microcosmic fractures based on nanoindentation experiment

A nano-indentation and developmental technology, which is applied in testing material hardness, resources, instruments, etc., can solve problems such as low elastic modulus, difficulty in completing analysis in a short period of time, even in-situ real-time monitoring, and high cost of microscopic observation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

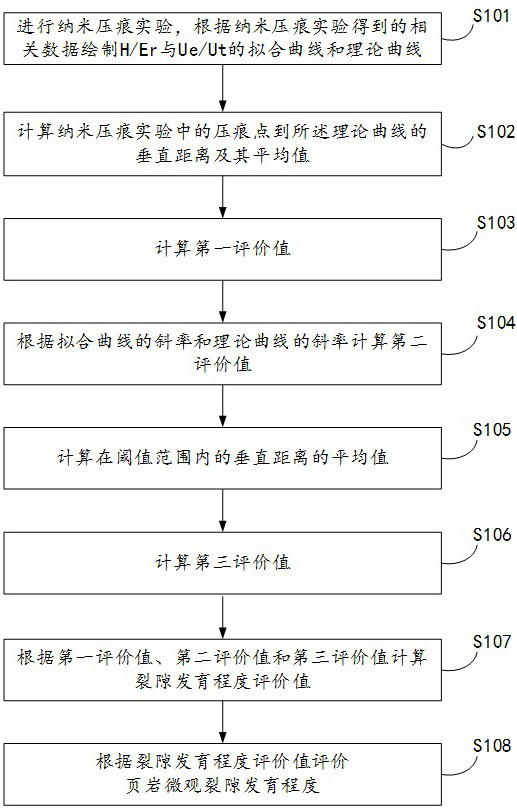

[0071] Such as figure 1 As shown, the embodiment of the present invention provides a method for evaluating the development degree of shale microscopic fractures based on nanoindentation experiments, including:

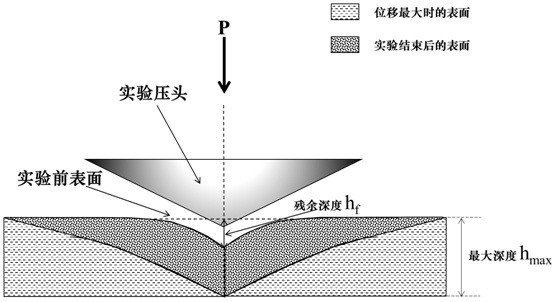

[0072] S101, performing an in-situ nanoindentation experiment, drawing a fitting curve and a theoretical curve of H / Er and Ue / Ut according to the relevant data obtained from the nanoindentation experiment, and calculating the slope of the fitting curve and the slope of the theoretical curve; wherein, Er is elastic modulus, H is contact hardness, Ue is elastic energy, Ut is total energy;

[0073] S102, calculating the vertical distance from the indentation point in the nanoindentation experiment to the theoretical curve and its average ;

[0074] S103, use the following formula to calculate the first evaluation value :

[0075]

[0076] In the formula, is the vertical distance in The number of indentation points in the interval, is the vertical distance...

specific Embodiment 1

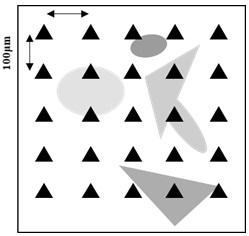

[0134] In this example, sample 1 is used to conduct nanoindentation experiments, and the relationship images of H / Er and Ue / Ut are drawn according to the relevant data obtained in the experiment, and the proportional function is fitted ,get is 0.250. According to the type or equivalent angle of the experimental indenter, a theoretical proportional curve is made, and the proportional coefficient of the theoretical curve for =0.231.

[0135] Draw a vertical line from the indentation point to the theoretical curve, obtain the value of the vertical line segment and record it as . draw and The relation curve of the calculated is 0.01995, then is 0.63636.

[0136] Statistically obtained for 16, is 78, is 121, the first evaluation value is calculated according to the formula The value is 0.69.

[0137] according to and Calculate the second evaluation value is 0.019.

[0138] by made at intervals The polar coordinate plot of is the radius to get...

specific Embodiment 2

[0141] In this example, sample 1 is used to conduct nanoindentation experiments, and the relationship images of H / Er and Ue / Ut are drawn according to the relevant data obtained in the experiment, and the proportional function is fitted ,get is 0.226. According to the type or equivalent angle of the experimental indenter, a theoretical proportional curve is made, and the proportional coefficient of the theoretical curve for =0.231.

[0142] Draw a vertical line from the indentation point to the theoretical curve, obtain the value of the vertical line segment and record it as . draw and The relation curve of the calculated is 0.011755, then is 0.67347.

[0143] Statistically obtained is 18, for 42, is 98, and the first evaluation value is calculated according to the formula The value is 0.49.

[0144] according to and Calculate the second evaluation value is 0.005.

[0145] by made at intervals The polar coordinate plot of is the radius t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com