Modified silicon-based material, preparation method thereof and lithium battery negative electrode material

A technology of silicon-based materials and modified silicon, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex process, silicon anode materials can not take into account the rate performance, cycle performance and first coulombic efficiency, etc., to achieve good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

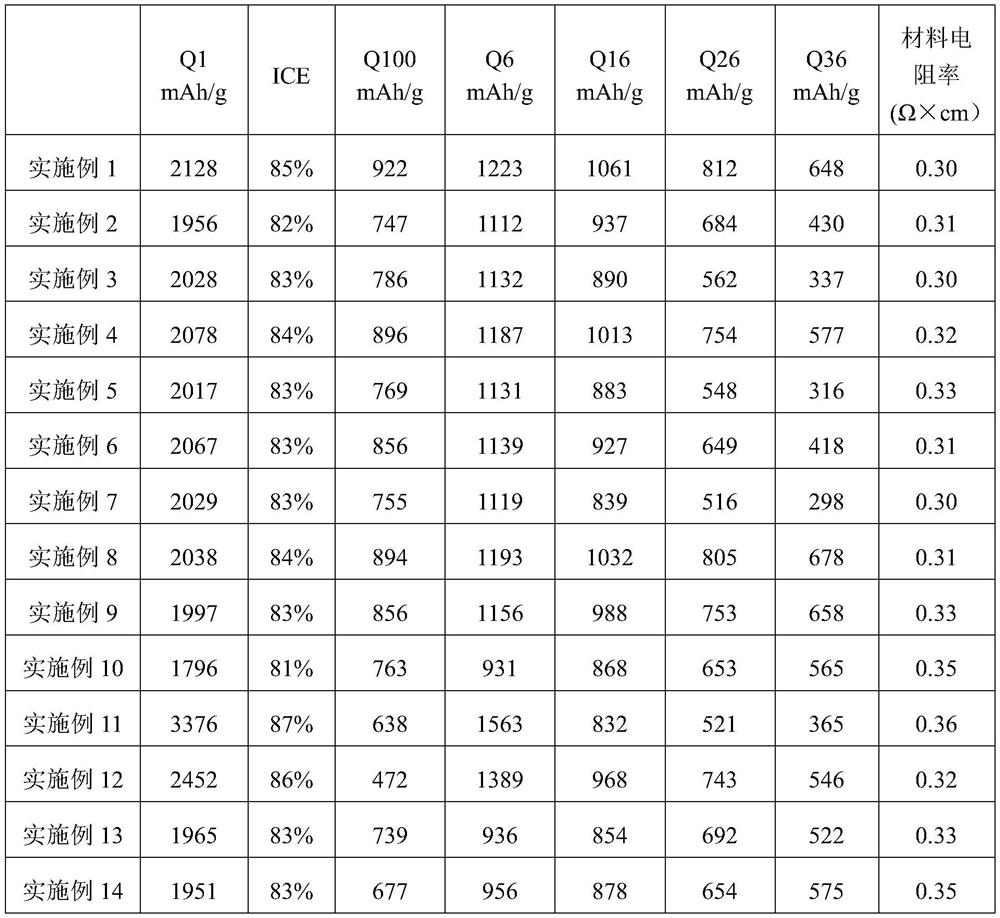

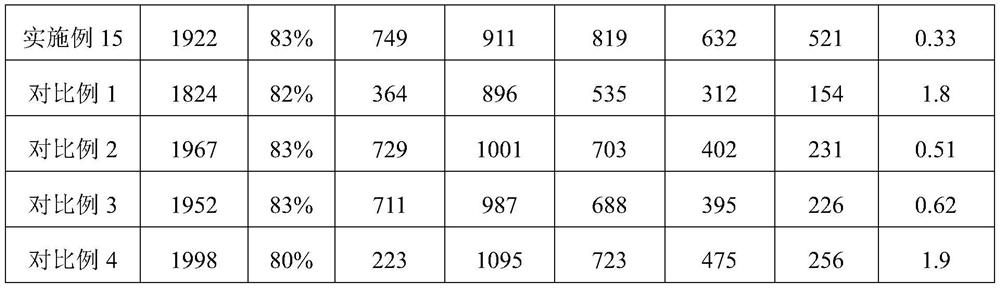

[0025] As described in the background technology section, the process of doping modified silicon-based materials in the prior art is either complicated, or the prepared silicon anode material cannot take into account good rate performance, cycle performance, and first Coulombic efficiency. In order to solve the above problems, the present invention provides a method for preparing a modified silicon-based material, which includes the following steps: Step S1, using a hydrothermal method to dope the silicon-based material with a dopant to obtain a doped silicon-based material ; wherein the weight ratio of the dopant to the silicon-based material is (0.01-0.1): 1; step S2, dispersing the doped silicon-based material in water to form a dispersion, and adding an oxidizing agent and a conductive polymer unit to the dispersion body, followed by in-situ polymerization to obtain a modified silicon-based material.

[0026] In the preparation method, the silicon-based material is firstly...

Embodiment 1

[0042] Add 0.1 g of SiO material (average particle size about 6 μm) into deionized water, slowly add 0.005 g of H under stirring 3 BO 3 , and continued to stir for 3 hours, then transferred to a 150mL hydrothermal kettle after stirring evenly, the volume of the solution accounted for 60% of the kettle volume, and reacted at 140°C for 24h. It was then centrifuged and washed with water and ethanol in sequence to obtain a doped silicon-based material. Add the doped silicon-based material into deionized water, add 0.12g of ferric chloride and 0.05g of pyrrole successively under continuous stirring, and in-situ polymerize at 25°C for 2h (the thickness of the formed conductive polymer shell is about 0.3μm). Finally, the modified silicon-based material with a core-shell structure was obtained after centrifugal washing.

Embodiment 2

[0044] Add 0.1 g of SiO material (average particle size about 6 μm) into deionized water, slowly add 0.01 g of H under stirring 3 BO 3 , and continued to stir for 3 hours, then transferred to a 150mL hydrothermal kettle after stirring evenly, the volume of the solution accounted for 60% of the kettle volume, and reacted at 140°C for 24h. It was then centrifuged and washed with water and ethanol in sequence to obtain a doped silicon-based material. Add the doped silicon-based material into deionized water, add 0.12g of ferric chloride and 0.05g of pyrrole successively under continuous stirring, and in-situ polymerize at 25°C for 2h (the thickness of the formed conductive polymer shell is about 0.3μm). Finally, the modified silicon-based material with a core-shell structure was obtained after centrifugal washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com