Cobalt-free positive electrode material, and preparation method and application thereof

A positive electrode material and positive electrode technology, applied in the field of cobalt-free positive electrode material and its preparation, can solve the problems of cation mixing material structure, instability, etc., achieve high ionic conductivity, improve stability, and facilitate Li+ diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

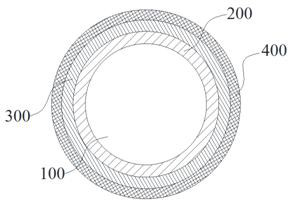

preparation example Construction

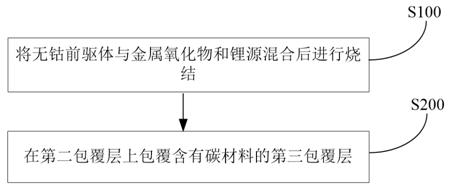

[0050] According to the method for preparing a cobalt-free positive electrode material of the present invention, by mixing the cobalt-free precursor with a metal oxide and a lithium source and then sintering, the first coating including a lithium salt compound can be sequentially formed on the surface of the cobalt-free precursor material in one step layer and the second coating layer comprising metal oxide, the first coating layer comprising lithium salt compound can inhibit the occurrence of side reactions on the surface of the positive electrode material, which is beneficial to improve the stability of the material, and the formed second coating layer comprising lithium salt compound A cladding layer has a high ionic conductivity, which is beneficial for Li + Diffusion, the second coating layer including metal oxide can improve the stability of the cobalt-free positive electrode material, and then form the third coating layer including carbon material on the surface of the s...

Embodiment 1

[0057] The method of preparing the positive electrode:

[0058] (1) First, the cobalt-free precursor (chemical formula is Ni 0.75 mn 0.25(OH) 2 ), LiOH·H 2 O carry out ball milling, the mass ratio of material and grinding beads is 1:5, the number ratio of large and small beads is 1:2, the diameter of large beads is 10mm, the diameter of small beads is 5mm, the speed of ball milling is 300r / min, and the time is 2h. After it is completed , join MoO 3 (Co-free precursor, LiOH·H 2 O, MoO 3 The molar ratio is 1:2.2:1), ball milling again at the same speed for 2 hours;

[0059] (2) Separate the above mixture into beads, then place it in a tube furnace for sintering at 600°C for 6 hours, the heating rate is 5°C / min, the sintering atmosphere is oxygen atmosphere, and NM is obtained after cooling with the furnace x @Li 2 MoO 4 -MoO 3 Materials, @ here and below only means wrapping;

[0060] (3) Using a high-speed stirrer, set the speed at 1200r / min, disperse single-walled CN...

Embodiment 2

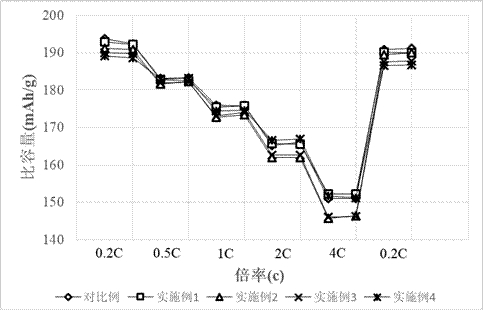

[0065] In step (3) of Example 1, the single-walled CNT accounted for 0.25wt% of the cobalt-free positive electrode material was replaced with the single-walled CNT accounted for 0.5wt% of the cobalt-free positive electrode material. In the obtained cobalt-free positive electrode material, the first coating layer, the second The thickness ratio of the cladding layer and the third cladding layer is 3:5:6.5, and the rest of the process is the same as in Example 1. The obtained half-cell rate performance, cycle performance and electrochemical impedance (EIS) at 50% SOC are tested. The result is as Figure 3-Figure 5 and Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com