Lithium battery and preparation method thereof

A lithium battery and metal lithium technology, which is applied in the manufacture of lithium batteries, electrolyte batteries, electrodes, etc., can solve the problems of poor storage performance of lithium ion batteries, easy formation of lithium dendrites, and inability to discharge at high rates of lithium primary batteries. Taking into account storage and rate performance, long cycle life, and the effect of improving specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

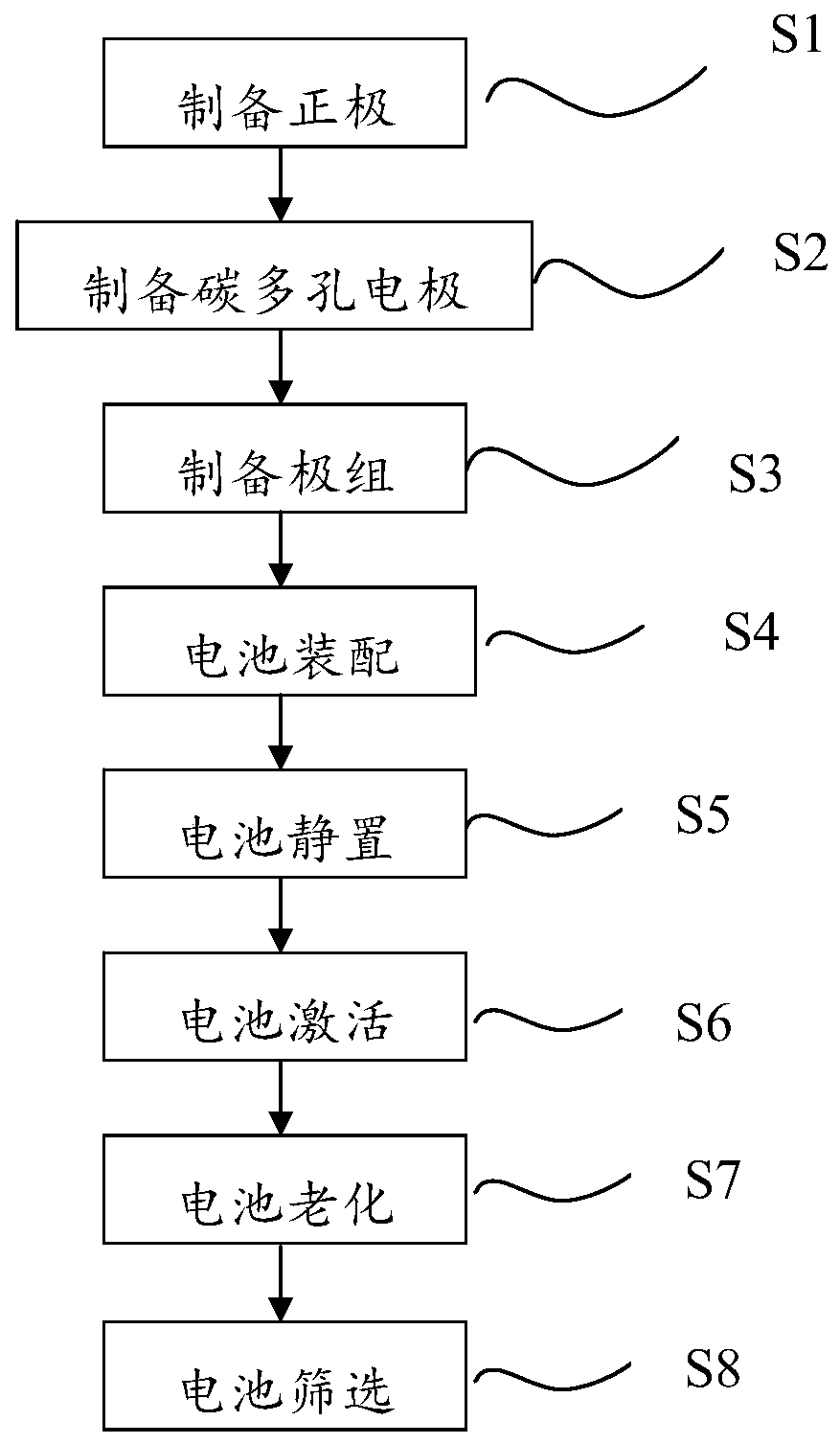

[0048] In terms of specific implementation, the preparation method of the lithium battery includes the following main steps:

[0049] Step 1: Prepare positive electrode

[0050] First, one or more kinds of lithium-containing metal composite oxides, conductive agents, and binders are fully mixed in a solvent in a certain proportion, and then the uniformly mixed slurry is coated on the upper and lower sides of the positive electrode current collector according to a certain surface density. On both sides, the solvent in the mixture is dried at the same time to obtain a semi-finished pole piece. Roll the semi-finished pole piece according to a certain compaction density, cut the pole piece according to a certain width, then dry the positive pole piece under vacuum conditions at a suitable temperature and time, and finally weld one or Multiple drained tabs are prepared to obtain the positive electrode;

[0051] Step 2: Preparation of Carbon Porous Electrode

[0052] First, one o...

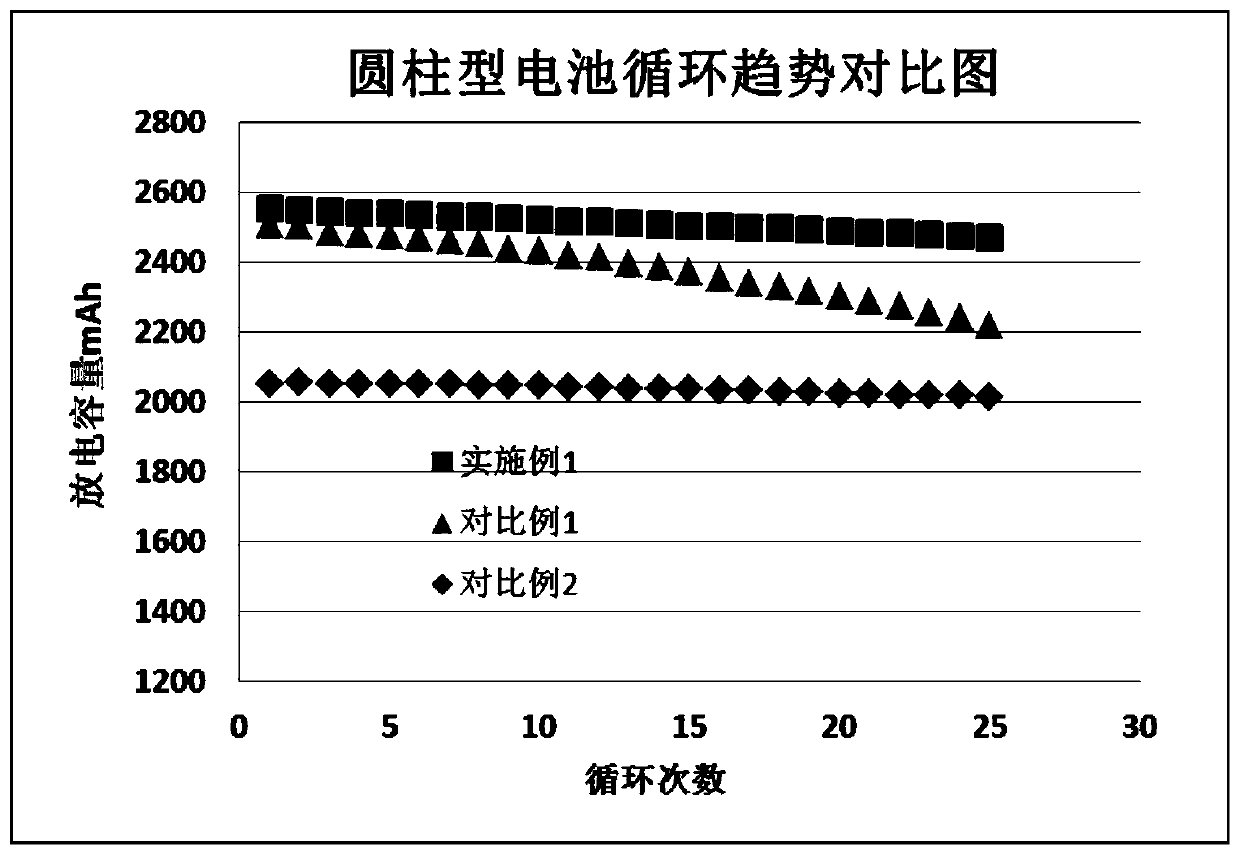

Embodiment 1

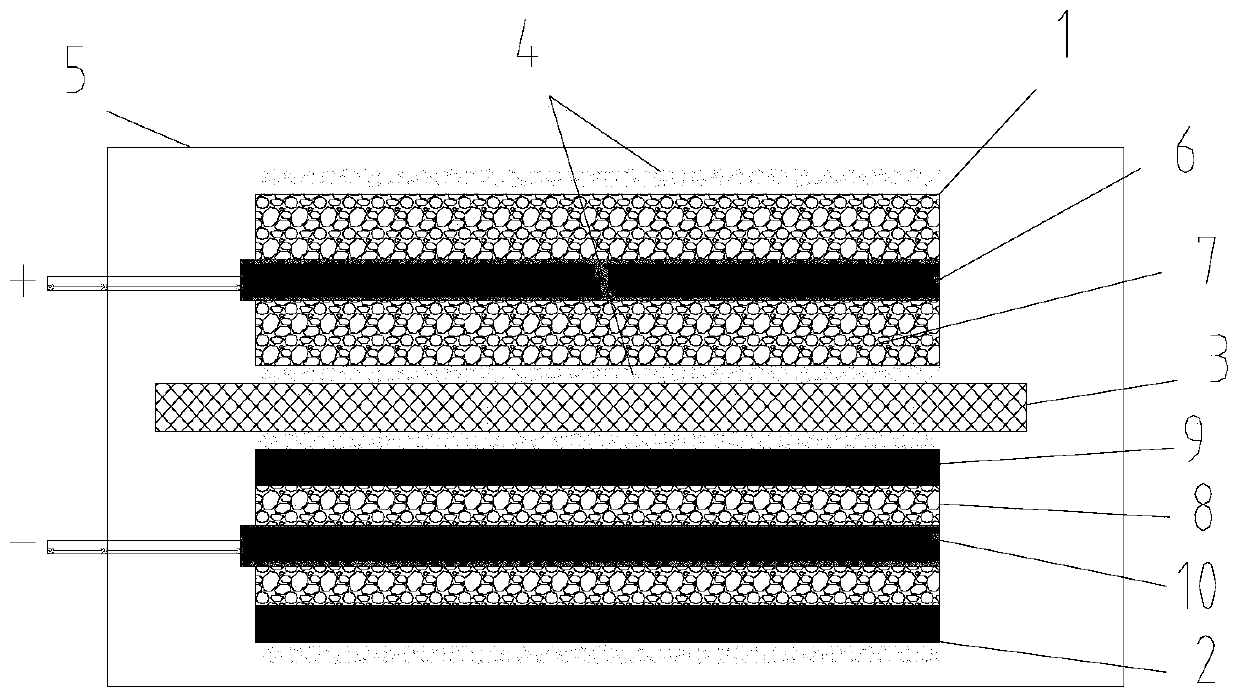

[0073] This embodiment provides a cylindrical lithium battery, including a cylindrical stainless steel casing, a cover, a cell and an electrolyte disposed in the casing, and the cell is formed by intertwining a positive electrode, a separator, and a negative electrode.

[0074] Positive electrode adopts NCM 523 (LiNi 0.5 co 0.2 mn 0.3 o 2 ) as the active material (reversible gram capacity of 140mAh / g charged to 4.1V), using carbon black SP, carbon nanotube CNT composite conductive agent, polyvinylidene fluoride PVDF as the binder, and the electrode ratio is: Active material: Conductive agent: binder = 95:2.5:2.5.

[0075] The negative electrode is composed of a carbon porous electrode and a lithium metal layer. The active material in the carbon porous electrode is artificial graphite (reversible gram capacity of 350mAh / g), the conductive agent is carbon black SP, the binder is CMC and SBR, and the electrode ratio For: active material: conductive agent: binder = 94.8:2:3.2...

Embodiment 2

[0090] This embodiment provides a soft-pack lithium battery, which includes a square-shaped aluminum-plastic film casing, a battery cell and an electrolyte disposed in the casing, and the battery cell is formed by stacking a positive electrode, a separator, and a negative electrode in a zigzag shape.

[0091] The components and ratios of the positive and negative electrodes are exactly the same as in Example 1.

[0092] The diaphragm adopts a 12μm thick PE substrate, and one side is coated with a 4μm thick ceramic coating.

[0093] The electrolyte is lithium salt LiFP 6 A mixture dissolved in an organic non-aqueous solvent, wherein the organic non-aqueous solvent is LiFP with a concentration of 1.1mol / L 6 +EC / EMC / DEC / PP.

[0094] The preparation method of the flexible package lithium battery of the present embodiment is as follows:

[0095] 1. Prepare the positive electrode: use N-N dimethylpyrrolidone (NMP) as the solvent for the positive electrode active material, conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com