Humidifier for fuel cell system and debugging and working method thereof

A technology for fuel cell systems and humidifiers, which is applied in the field of humidifiers and humidifiers for fuel cell systems, and can solve problems such as reduced humidification efficiency, uneven distribution of water vapor, and inability to adjust the humidity of the dry air flow of the humidifier. Achieve the effect of prolonging the service life and improving the accuracy of humidity regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

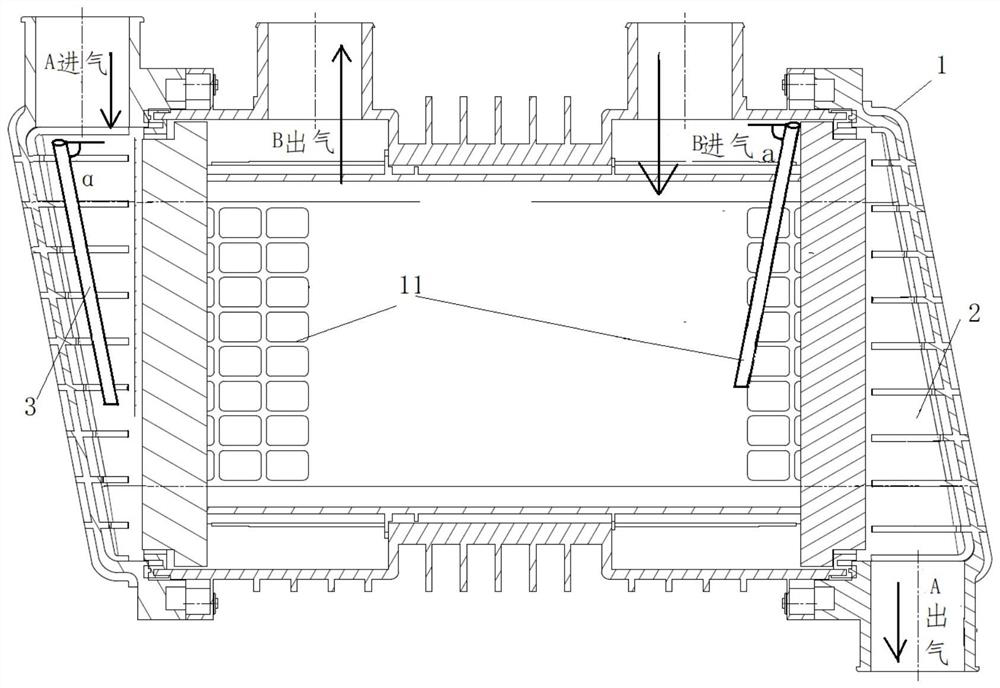

[0067] Example 1: Taking the first pilot valve plate 2 as 0° to 90° and the second pilot valve plate 3 as 0° to 90° as an example, there are 8100 arrangements and combinations of the first pilot valve plate 2 and the second pilot valve plate 3, specifically is {0°, 0°}, {0°, 1°}···{0°, 90°};

[0068] {1°, 0°}, {0°, 1°}···{0°, 90°};

[0069] ···

[0070] {90°, 0°}, {0°, 1°}···{0°, 90°}.

[0071] Then each humidity is corresponding to the combination of the opening degrees; and the opening combinations are entered into the controller 5 one by one according to the humidity range; since in the case of a given air flow, each opening combination represents a humidity in a high probability value. When encountering a humidity value and there are multiple corresponding opening combinations, the opening combination whose opening variation trend matches the adjacent humidity value should be selected.

[0072] In addition to the above-mentioned embodiments, the present invention als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com