Strong-flavor soybean oil, preparation method and application thereof

A technology of oil and residual oil, which is applied in the direction of application, edible oil/fat, and food ingredients as odor improvers, etc. It can solve the problems of fragrance loss, environmental pollution, and affecting consumers' desire to buy, and achieve the effect of inhibiting the formation of greasy smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention relates to a new flavor soybean oil and its preparation method and use, or a strong aroma soybean oil and its preparation method and use, or a flavor soybean oil and its preparation method and use, or a soybean oil and its Preparation method and use, or flavored oil and its preparation method and use, or flavored oil composition and its preparation method and use.

[0029] The preparation method of flavored oil (hereinafter sometimes referred to as "the preparation method of the present invention" or "preparation method") is characterized in that it includes the following steps: mixing the degreased oil raw material with the oil, so that the system contains residual oil The stability is 10~2, so as to obtain the flavor oil.

[0030] In the preparation method of the present invention, the degreased oil raw material is mixed with the oil and then heat-treated so that the stability of the residual oil in the system is 10-2 to obtain the flavored oil. ...

Embodiment

[0112] EXAMPLES The present invention will be specifically described below with reference to examples, but the present invention is not limited to these examples. The soybeans and soybean oil used in the examples come from Yihai Kerry (Harbin) Grain, Oil and Food Industry Co., Ltd.; the reagents such as n-hexane are purchased from Sinopharm Group; the equipment information used in the examples is as follows: Midea Commercial Microwave Oven (EMA34GTO-SS ); Xiangge Oil Press (PX7); Roasting Machine (CBR-101); Oven (BINDER-FD115); Vacuum Pump (Edward-RV12); Magnetic Stirring Heating Table (IKA-CMAG-HS7); Machine (400Y), reaction kettle (PARR); electronic scale (SARTORIUS-BSA6202SCW), collector type constant temperature heating magnetic stirrer (Yuhua-DF-101S).

preparation example

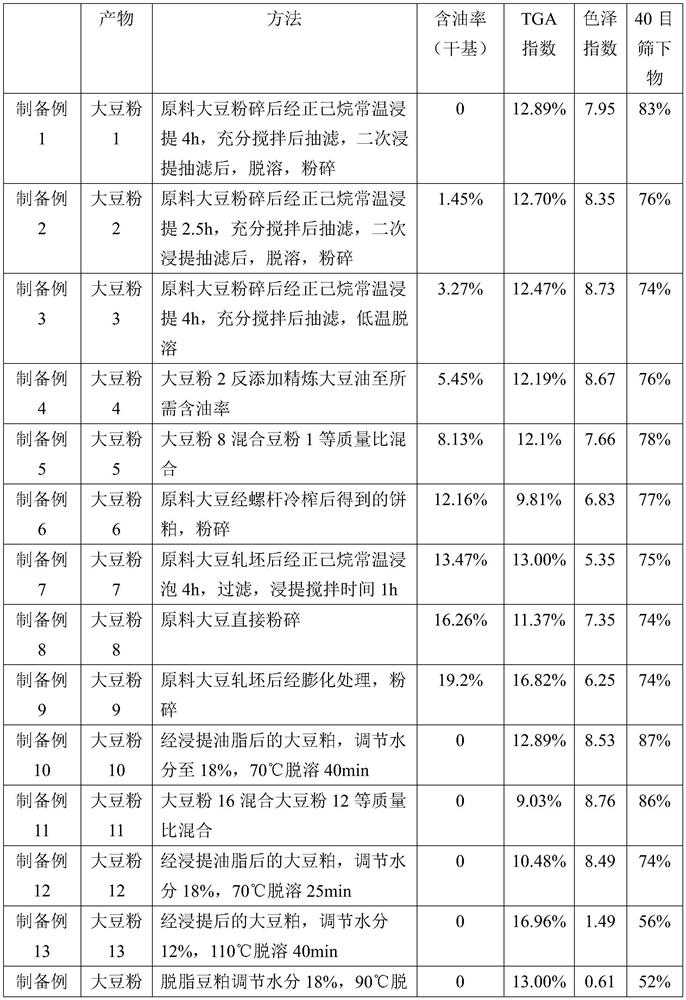

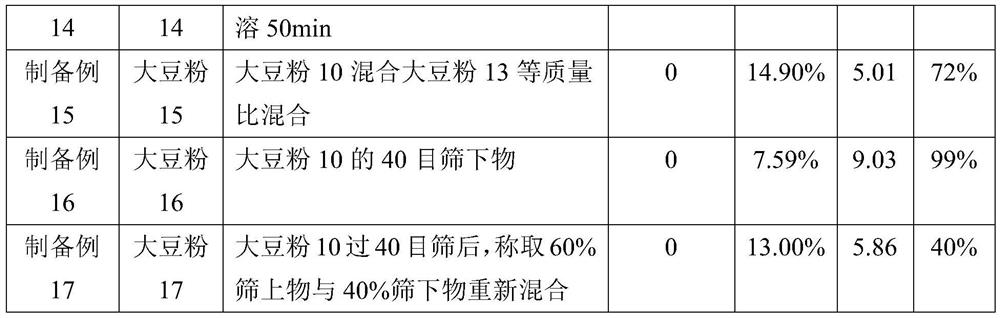

[0114] Commercially available soybeans were used to prepare different raw materials according to the method in Table 1, and the oil content, TGA index, color index, and particle size were tested.

[0115] Table 1 raw material preparation method

[0116]

[0117]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com