Granulating device for special feed for experimental animals

A technology for experimental animals and feed, applied in the direction of animal feed, animal feed molding or processing, feed, etc., can solve the problems of small quantity, waste and large scale of specially formulated feed, and achieve the effects of improving welfare, saving time and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

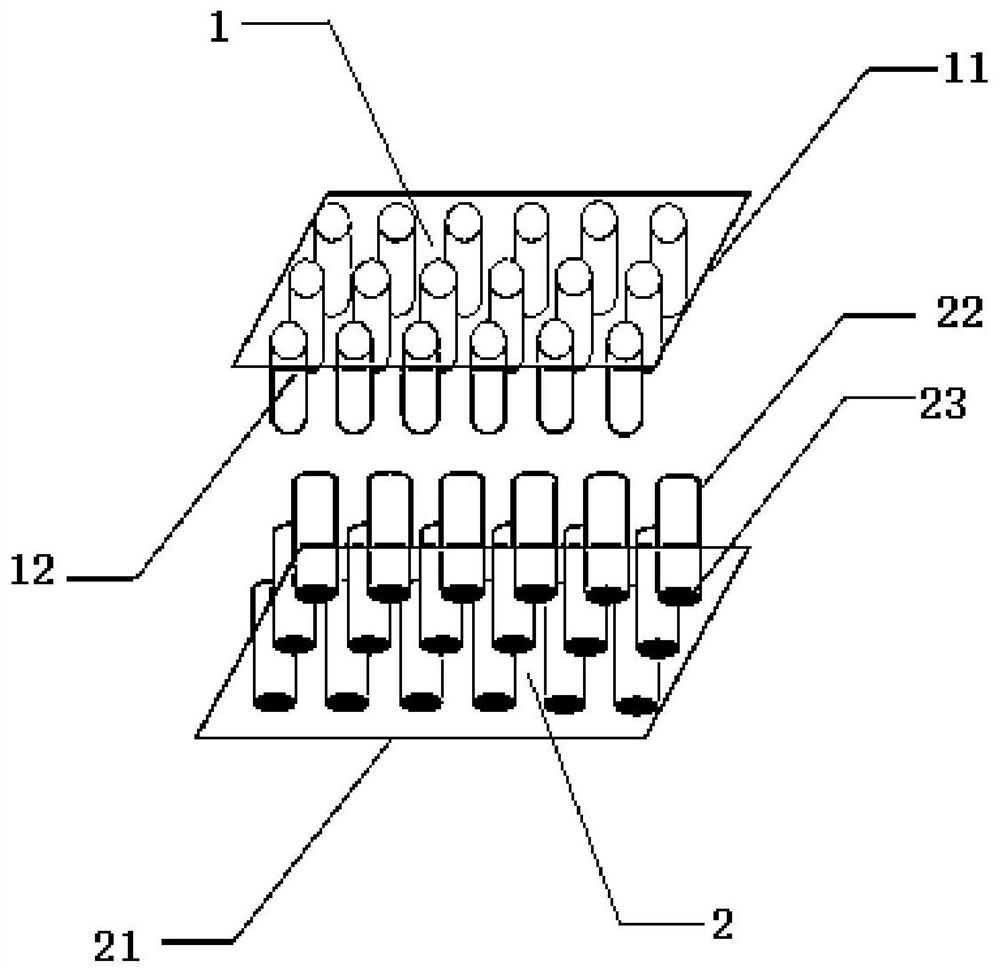

[0031] Such as figure 1 As shown, the granulation device for the specially formulated feed for experimental animals includes an upper body 1 and a lower body 2 .

[0032] The upper body 1 includes an upper supporting surface 11 and a plurality of closed cylinders 12, the upper ends of which are fixedly connected to the surface of the upper supporting surface 11, and the dimensions of the plurality of closed cylinders 12 are the same.

[0033] The lower body 2 includes a lower supporting surface 21 and a plurality of semi-closed cylindrical sleeves 22, the lower ends of the plurality of semi-closed cylindrical sleeves 22 are fixedly connected to the surface of the lower supporting surface 21, and the plurality of semi-closed cylindrical sleeves 22 are the same size. The position of the lower supporting surface 21 corresponding to the semi-closed cylindrical sleeve 22 is hollow. Both the upper supporting surface 11 and the lower supporting surface 21 can use transparent plates...

Embodiment 2

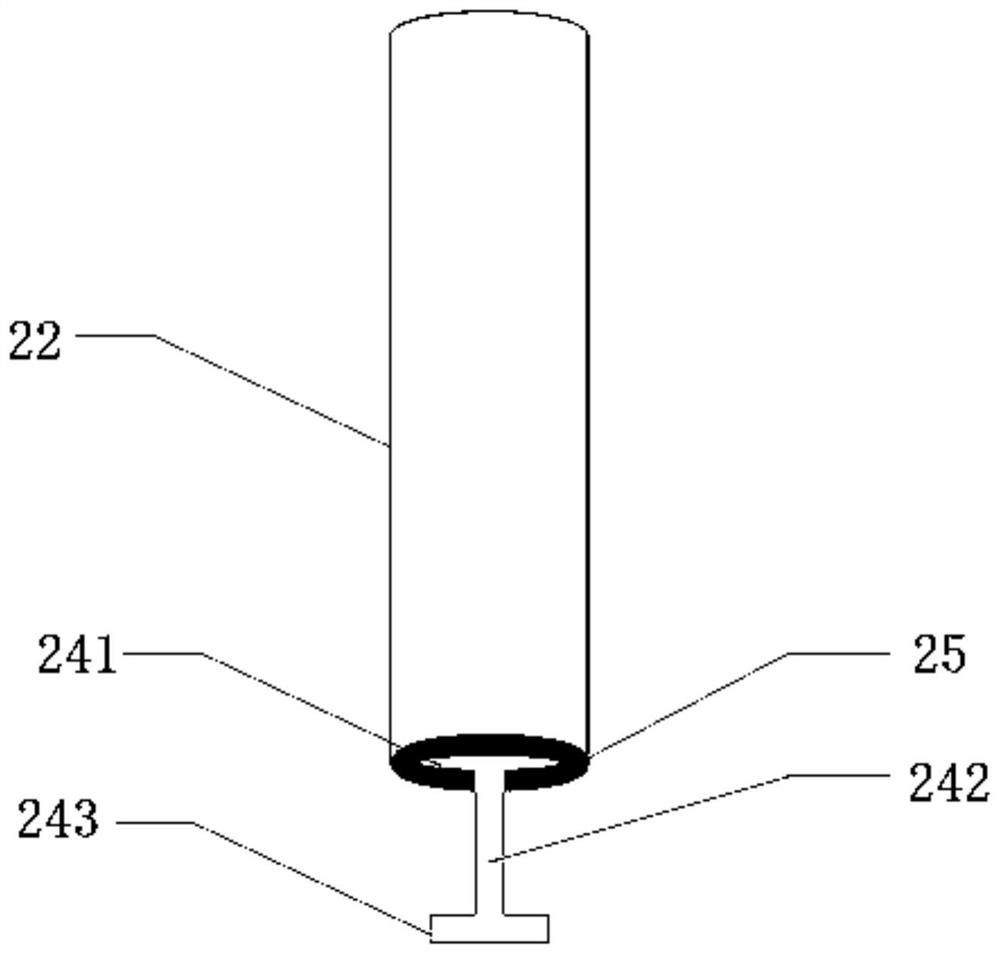

[0038] Such as figure 2As shown, on the basis of the structure of the granulation device of the experimental animal feed in Example 1, the lower surface of the disc device 23 is connected to the piston type push rod 24, and the piston type push rod 24 includes a piston 241 and a push rod connected by a connecting rod 242. Rod 243, the piston is set in the semi-closed cylindrical sleeve 22 and supported by the receiving edge 25, and the push rod is arranged below the receiving edge 25 of the semi-closed cylindrical sleeve 22, and the wafer can be moved by pushing the piston-type push rod 24. The device 23 freely moves up and down in the semi-closed cylindrical sleeve 22 .

Embodiment 3

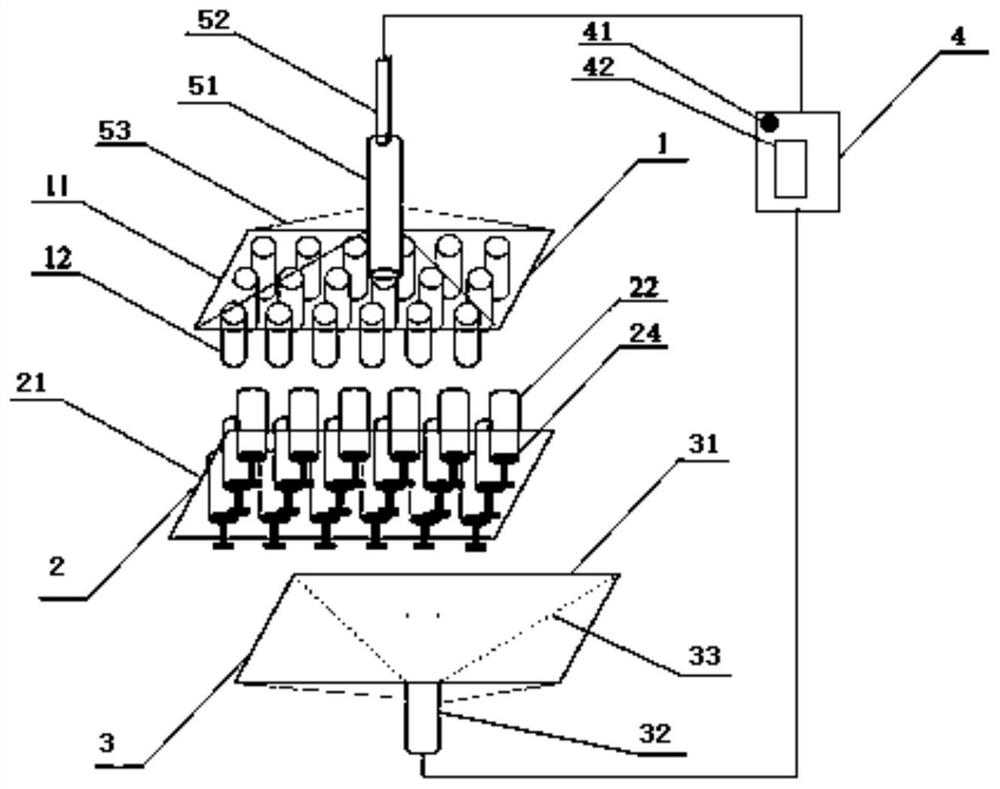

[0040] Such as image 3 As shown, on the basis of the structure of the granulation device for the special feed for experimental animals in Example 2, it also includes an upper force applying device 5 , a lower force applying device 3 and a controller 4 .

[0041] The upper force application device 5 includes an upper force application arm 51 and a plurality of upper connecting columns 53, the lower surface of the upper force applying arm 51 is connected at the center position of the upper surface of the upper supporting surface 11, and the upper ends of the plurality of upper connecting columns 53 are connected On the upper force applying arm 51, the lower ends of a plurality of upper engaging columns 53 are respectively connected to the upper surface of the upper supporting surface 11, and the lower ends of the plurality of upper engaging columns 53 are symmetrical at the connection points of the upper supporting surface 11, so that the upper When the force-applying arm 51 pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com