Mopping machine system

A technology of a mopping machine and a power mechanism, which is applied in the field of mopping machine systems, can solve the problems of poor sewage collection effect, sewage clogging, and inconvenient user maintenance, etc., to facilitate cleaning and maintenance, prevent clogging, and improve reliability. and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

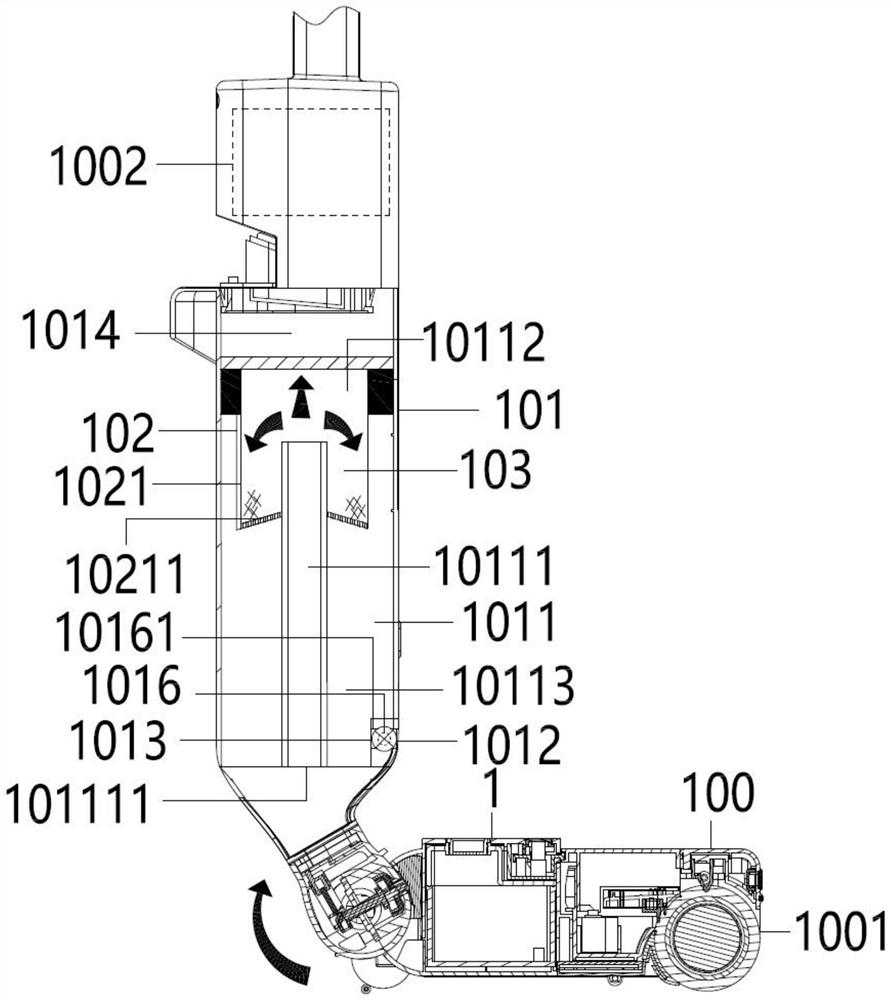

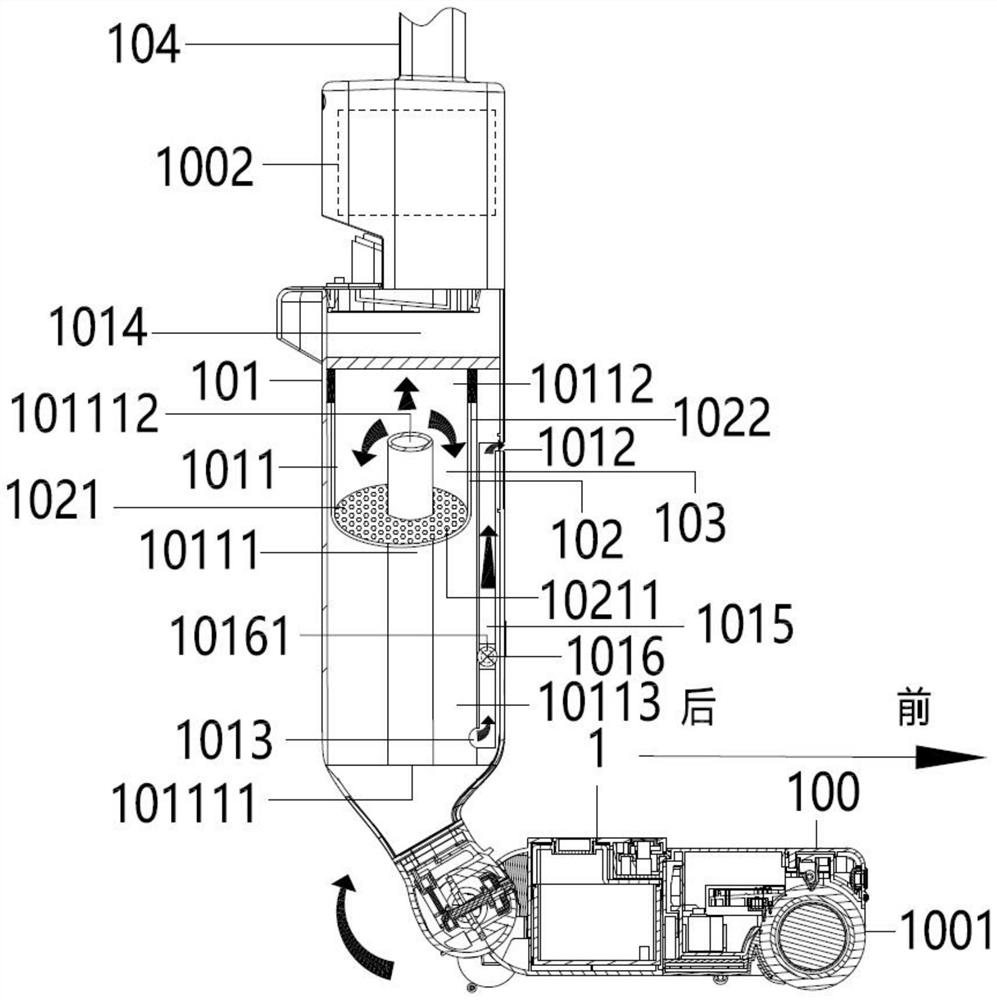

[0056] Embodiment: mopping machine system of the present invention, as Figure 1 to Figure 7 As shown in the configuration, the system mainly includes a mopping machine 1 and a base station 2. The mopping machine 1 mainly performs the mopping and cleaning function on the ground. 1 For the issue of maintenance and processing, the user only needs to perform maintenance and processing on the base station 2 on a regular or periodic basis, so as to improve user experience.

[0057] The floor mopping system of this solution includes a floor mopping machine 1, a mopping main body 100 is arranged on the floor mopping machine 1, a movable mopping part 1001 is installed on the mopping main body 100, and the mopping part 1001 moves to mop the ground For cleaning treatment, the mopping machine 1 also includes a power mechanism 1002. The power mechanism 1002 is used to provide power to move the sewage on the mop 1001 for collection. When the power mechanism 1002 starts to work, it absorbs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com