Engineering garbage recovery device

A recycling device and garbage technology, applied in the direction of dust removal, cocoa, grain processing, etc., can solve the problems affecting recycling, increasing labor, affecting the surrounding environment, etc., to achieve the effect of uniform size, reducing air pollution, and preventing diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

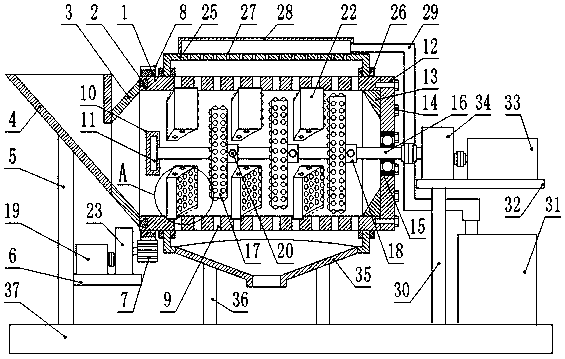

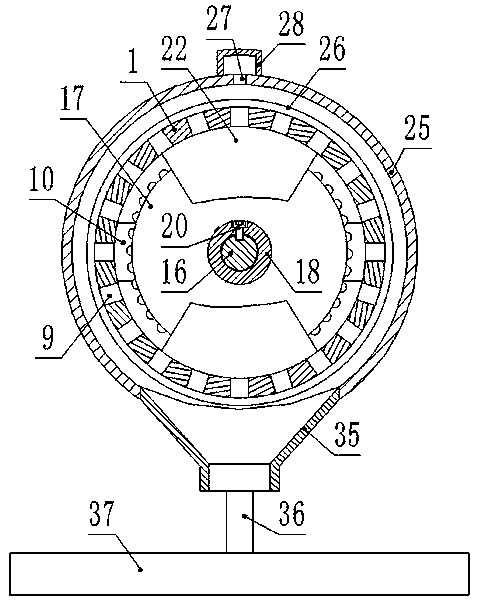

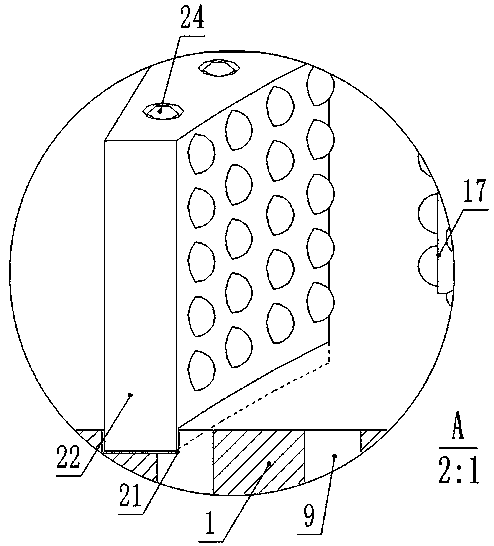

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0015] Such as figure 1 , figure 2 , image 3 As shown, a device for recycling engineering waste includes a cylinder body 1, which is characterized in that: one end of the cylinder body 1 is provided with a cover plate 12, the cover plate 12 is disc-shaped, and the cover plate 12 is passed through several bolts 14 is fixedly connected with the side end of the cylinder body 1, a bearing 15 is embedded and fixed in the center of the cover plate 12, and the outer ring of the bearing 15 is fixedly connected with the contact point of the cover plate 12, and a tapered shape is fixed on the side wall of the cover plate 12. The retaining ring 13, the tapered retaining ring 13 is arranged in the cylinder body 1, and the outside of the tapered retaining ring 13 is fitted and slidably connected with the inner wall of the cylinder body 1, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com