Grinding roller device of medium-speed mill

A technology of coal pulverizers and grinding rollers, which is applied in the direction of grain processing, etc., can solve the problems of thread wear, small size, and poor blowback effect of the hinge seat, so as to increase the outlet airflow velocity, increase the labyrinth seal structure, improve the The effect of wind pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

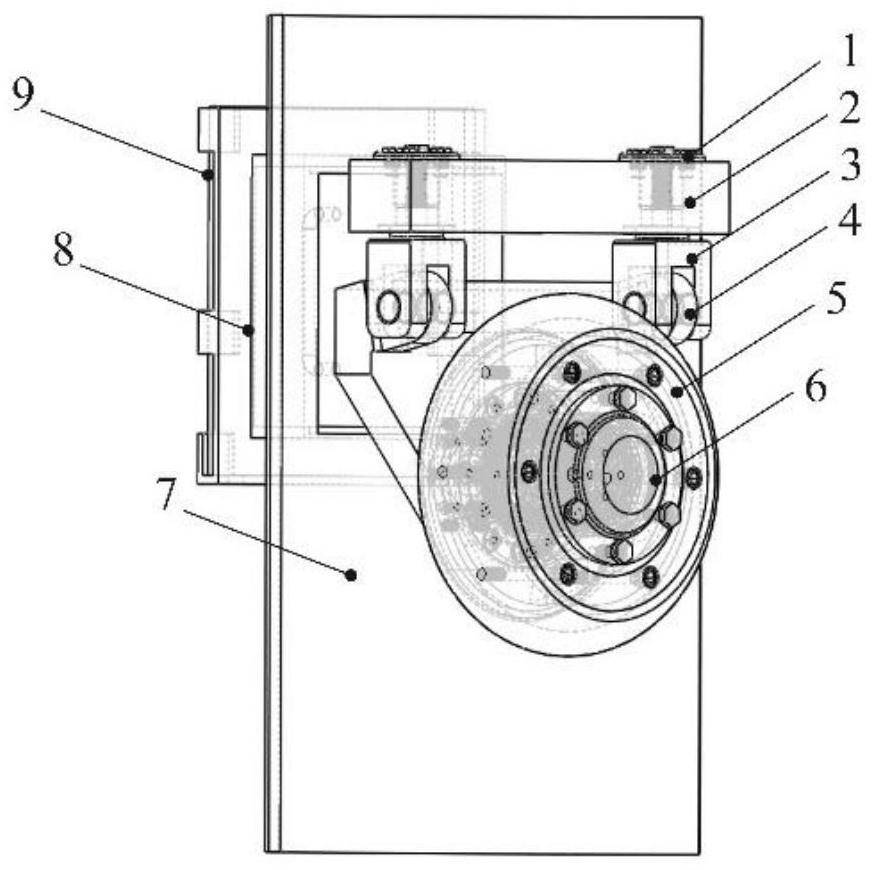

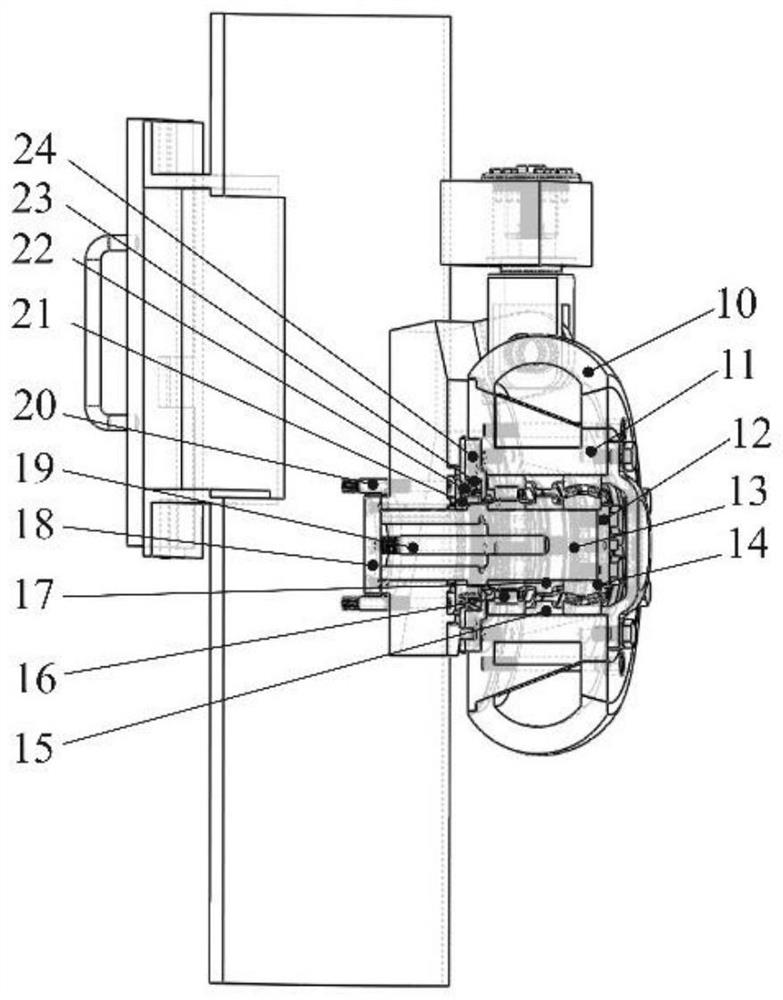

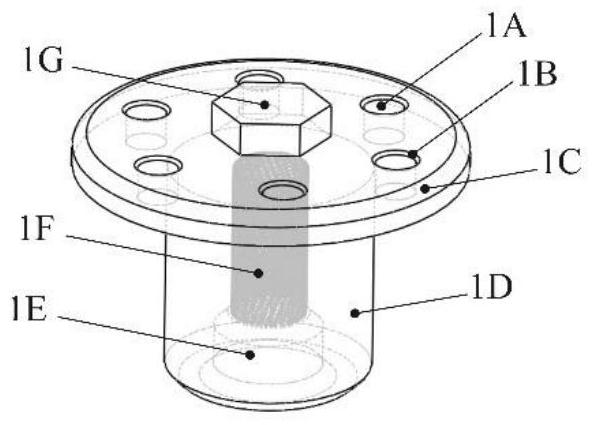

[0034] Such as figure 1 figure 2 As shown, a medium-speed coal mill roller device of the present invention is mainly composed of a shaft seat fixing part 1, a press frame 2, a shaft seat 3, a roll frame 4, a wedge ring 5, an end cover 6, and a mill Shell 7, observation window 8, observation window cover 9, self-aligning bearing 14, bearing outer spacer 15, roller bearing 16, bearing inner spacer 17, left pressure plate 18, roller core 11, axial air pipe 19, shaft sleeve 21 , a transparent cover 22, an oil seal 23 and a top cover 24; the press frame 2 arranged in the mill casing 7 is provided with a hinge seat fixture 1 connected to the hinge seat 3, and the hinge seat 3 is hinged with a roller frame 4 that can freely fine-tune the angle of the grinding roller when the grinding condition changes instantaneously. The sleeve 21 is provided with a roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com