Precast building composite board and application structure thereof

A composite plate and pre-casting technology, which is applied in building components, building structures, construction, etc., can solve problems such as difficult construction, shortened service life, and cumbersome manufacturing, and achieves convenient replacement, modification and maintenance, durable structure, and low price. Affordable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

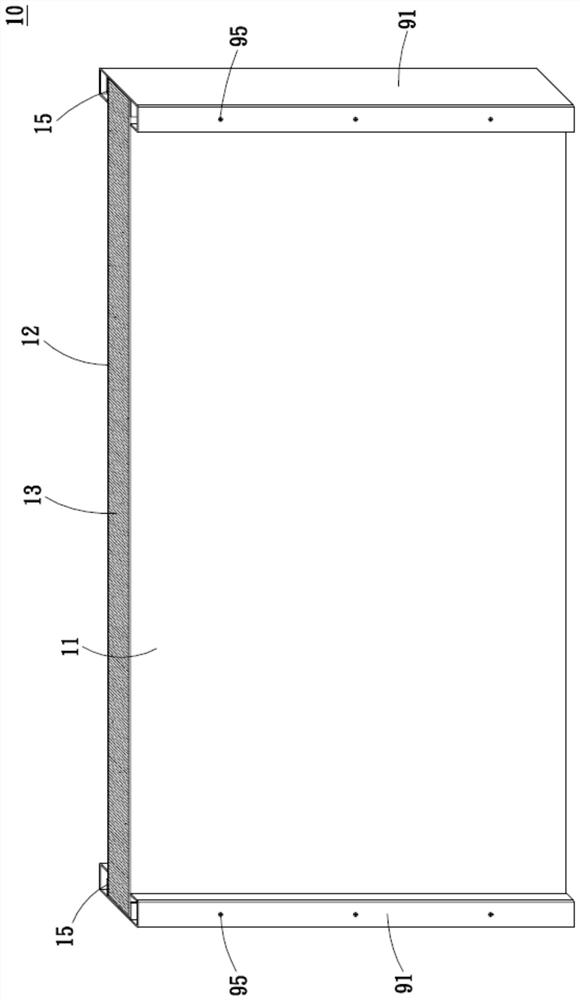

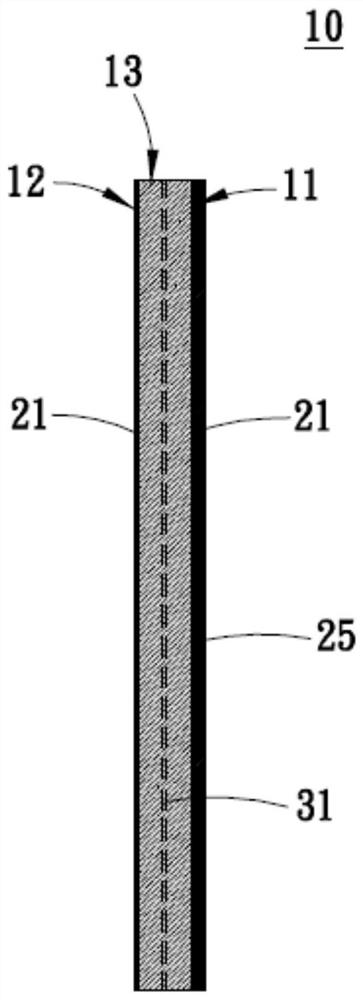

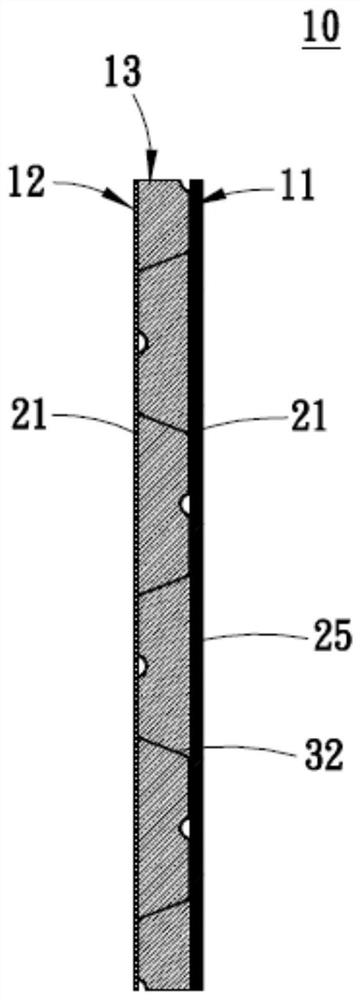

[0059] For the convenience of understanding the content of the present invention and the effects that can be achieved, the specific embodiments are listed in conjunction with the drawings, and the details are as follows: Please refer to Figure 1 to Figure 5 As shown, a precast building composite board and its application structure provided by the present invention mainly include: a multi-layer composite unit board body 10, the unit board body 10 has at least a first surface layer 11, a second Surface layer 12 and a filling inner layer 13, but the actual is not limited to this, wherein

[0060] The first surface layer 11 is arranged on one side of the unit plate body 10;

[0061] The second surface layer 12 is provided at a distance from the first surface layer 11, and is provided on the other side of the unit plate body 10, and;

[0062] The filling inner layer 13 is arranged between the first surface layer 11 and the second surface layer 12;

[0063] In a preferred embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com