Wine brewing machine

A technology of brewing machines and heat exchange tubes, which is applied in the field of brewing machines, can solve the problems of poor energy saving effect and heat loss that cannot be recycled, and achieve the effects of reducing workload, reducing labor costs, and avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Liquor has a saying that "aroma production depends on fermentation, and aroma enhancement depends on distillation". It can be seen that fermentation and distillation are two very important links in the process of making baijiu. Before fermentation, the grain needs to be cooked and saccharified, and the distillation needs to condense and cool the wine steam. Currently, the wine brewing machines on the market can realize the cooking, fermentation and distillation processes, but the cooling process requires manual participation, and the grain in the pot needs to be transferred. Air-cooling and mixing koji on a larger dustpan or table in the room, resulting in the heat loss of cooked high-temperature grains that cannot be recycled.

[0045] Therefore, this embodiment provides a brewing machine, which can recycle the heat contained in the cooked high-temperature grains during the brewing process, and has a good energy-saving effect.

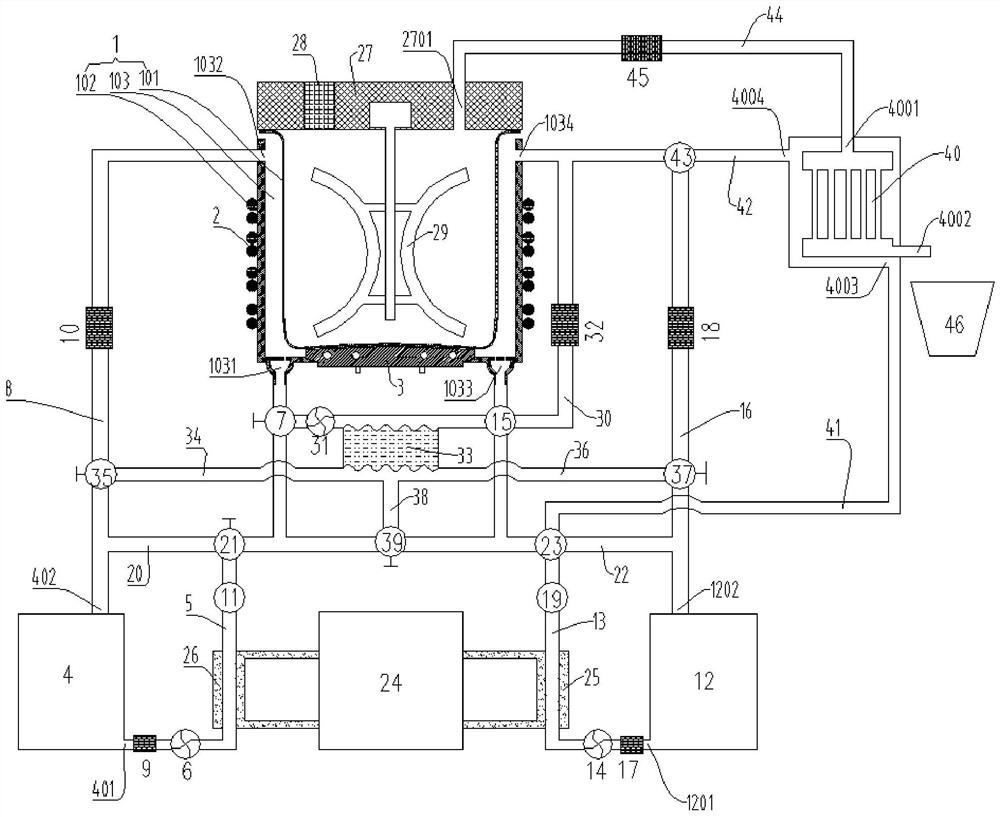

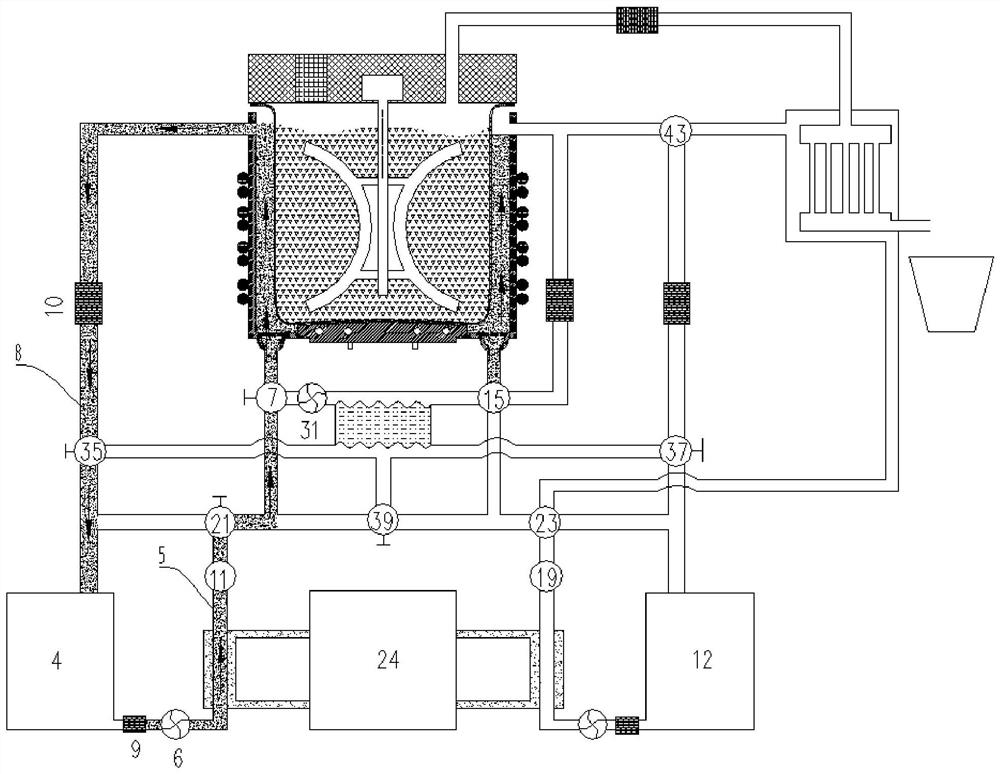

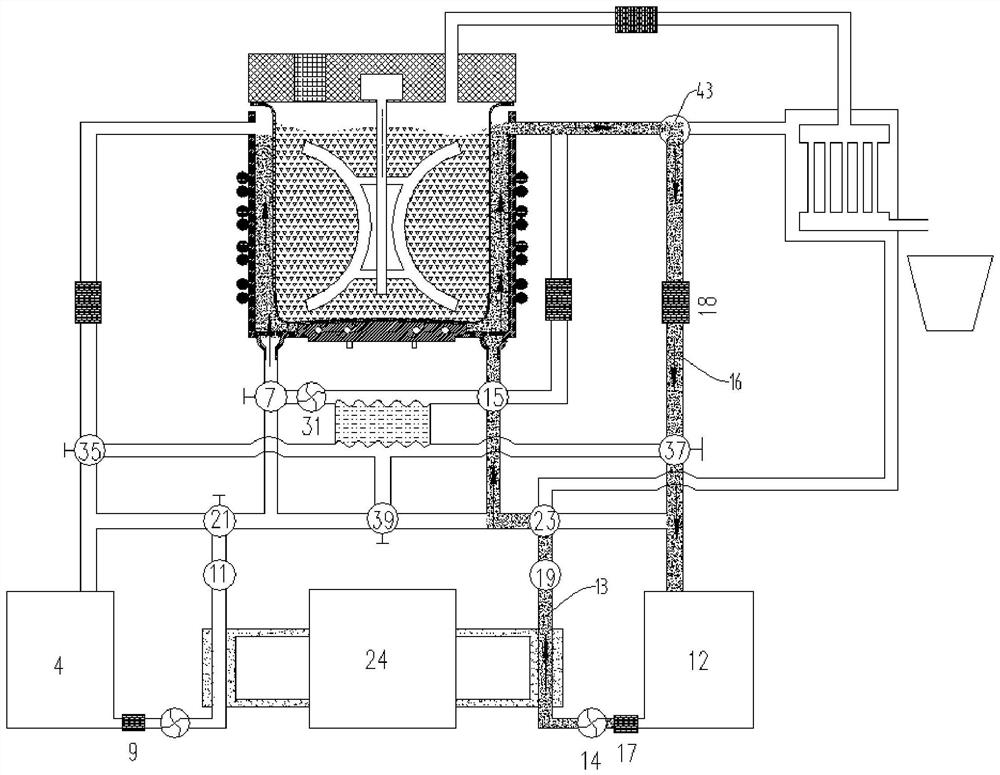

[0046] In one embodiment, as figure 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com