4.8-grade corrosion-resistant cold forging steel and production method thereof

A production method and technology of cold heading steel, applied in the field of cold heading steel, can solve the problems of less research work and low production cost of weather-resistant cold heading steel, reduce the risk of nodulation of molten steel, improve corrosion resistance, and shorten the solidification time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

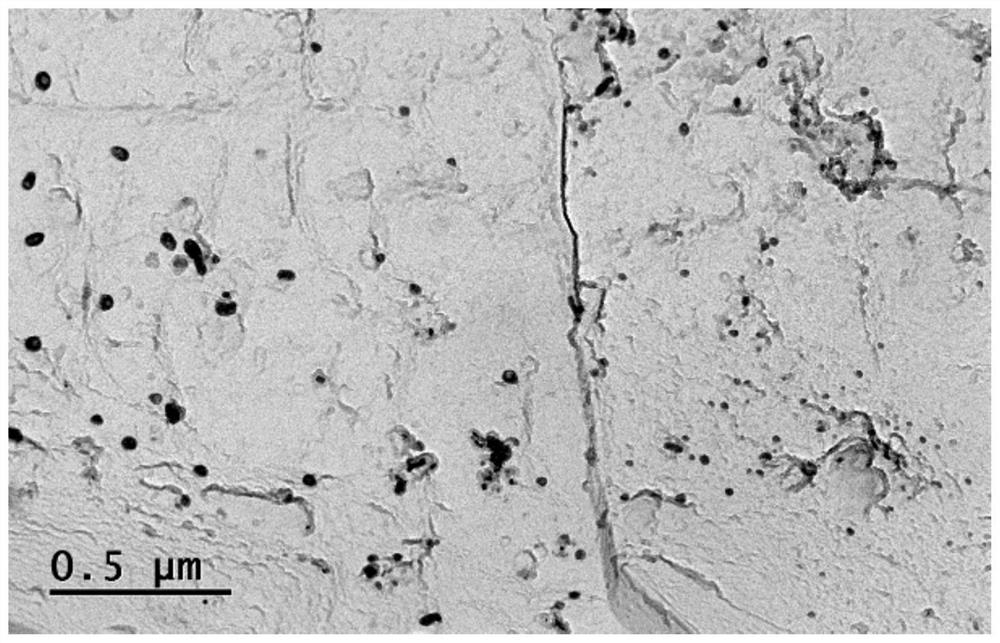

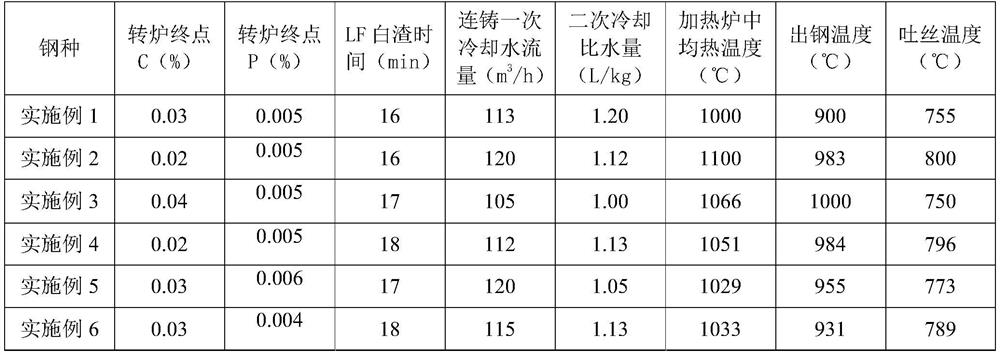

[0037] like figure 1 As shown, a 4.8-stage corrosion-resistant steel-resistant steel, including the following weight percentage of chemical components: C: 0.03%, Si: 0.15%, Mn: 0.50%, Alt: 0.030%, LA: 0.006%, CE : 0.012%, YB: 0.008%, P: 0.012%, S: 0.003%, the rest is Fe and other inevitable impurities. Different from the traditional addition of Cu, Cr, Ni precious alloy elements, the present invention can effectively reduce the manufacturing cost of the steel by adding low-cost LA, CE, YB rare earth elements. In the industrial atmospheric environment, YB can make MNS, A1 in steel 2 O 3 The like is mixed into spherical rare earth composite oxide, and the strong toughness of steel is improved by dispassion. YB, CE, LA is also enriched in the rust layer of steel, forming a form of elliptical complex (see figure 1 ), The size is 30 nm to 100 nm, which reduces the critical current density of the activated peak, and then reducing the active dissolution rate of the steel matrix, and its ...

Embodiment 2

[0053] The 4.8-stage corrosion-resistant cold press steel is maintained in accordance with Example 1, and the present embodiment includes the following weight percent chemical components: C: 0.07%, Si: 0.17%, Mn: 0.20%, Alt: 0.020%, LA: 0.01%, CE: 0.008%, YB: 0.009%, P: 0.013%, S: 0.002%, the rest is FE and other inevitable impurities.

[0054] The corrosion resistance index I of the 4.8-stage corrosion-resistant crossed steel of the present embodiment is 0.16, and the steel flow fluidity index L is 0.031.

[0055] The production method of the 4.8-stage corrosion resistant steel steel, including the following production steps: iron water pretreatment → steel water smelting → LF furnace refining → Square-billet cast → billet heating → wire rolling → Steymo Cooling wire cooling → φ 5.5 ~ 30mm wire strip finished product. It is pretreated with desulfurization, the desulfurization target value s ≤ 0.006%. The end of the steel smelting step control C is 0.02%, P is 0.005%, and the whit...

Embodiment 3

[0059] The 4.8-stage corrosion-resistant refurbished steel of the present embodiment is substantially consistent with the first embodiment, and the present embodiment includes the following weight percent chemical components: C: 0.04%, Si: 0.30%, Mn: 0.45%, Alt: 0.029%, LA: 0.012%, CE: 0.006%, YB: 0.01%, P: 0.011%, S: 0.003%, and the rest is Fe and other inevitable impurities.

[0060] The resistance index I of the 4.8-stage corrosion-resistant crossed steel of the present embodiment is 0.21, and the steel fluidity index L is 0.032.

[0061]The production method of the 4.8-stage corrosion resistant steel steel, including the following production steps: iron water pretreatment → steel water smelting → LF furnace refining → Square-billet cast → billet heating → wire rolling → Steymo Cooling wire cooling → φ 5.5 ~ 30mm wire strip finished product. It is pretreated with desulfurization, the desulfurization target value s ≤ 0.006%. The end of the steel smelting step control C is 0.04%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com