Tennis court stainless steel continuous welding metal roof construction method

A technology of welding metal and construction methods, applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems such as difficult welding quality control, difficult positioning and setting out, and affecting construction progress, and achieve quality solutions. Difficult to control, solve the effect of poor waterproof performance and reduce installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present specific embodiment is merely an explanation of the present invention, which is not limited to the present invention, and those skilled in the < It is required to be protected by patent law.

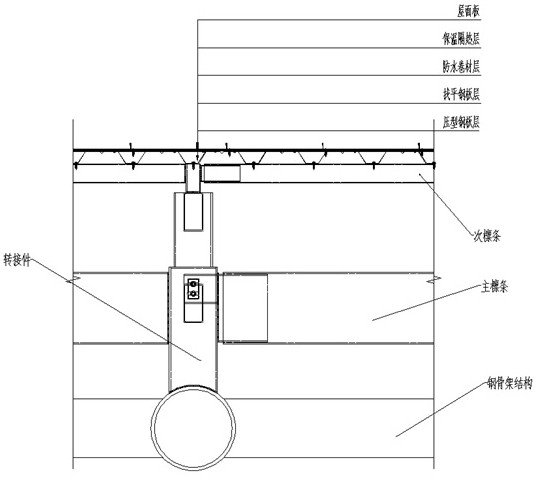

[0046] A tennis court stainless steel continuous welding metal roofing construction method, including the following steps,

[0047] Step 1, the steel skeleton support system review, determine the theoretical coordinates and elevation of the adapter in the steel skeleton structure through the BIM model, and the specific steps are:

[0048] 1) According to the construction of the process, the three-dimensional coordinates of the onset data that needs to be measured in time, including

[0049] Adapter coordinates, 檩 coordinates and fixed support coordinates; ensure the smooth development of construction, including the use of the instrument, steel tape measure, etc. Determine parallel to the direction of the baseline, using the "positive-in-mirror" method, using the level of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com