Chemical flooding injection well and production well blockage simulation device and method

A technology for simulating devices and production wells, applied in wellbore/well components, earthwork drilling and production, and production fluids, etc., which can solve problems such as lack of impact on oil displacement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

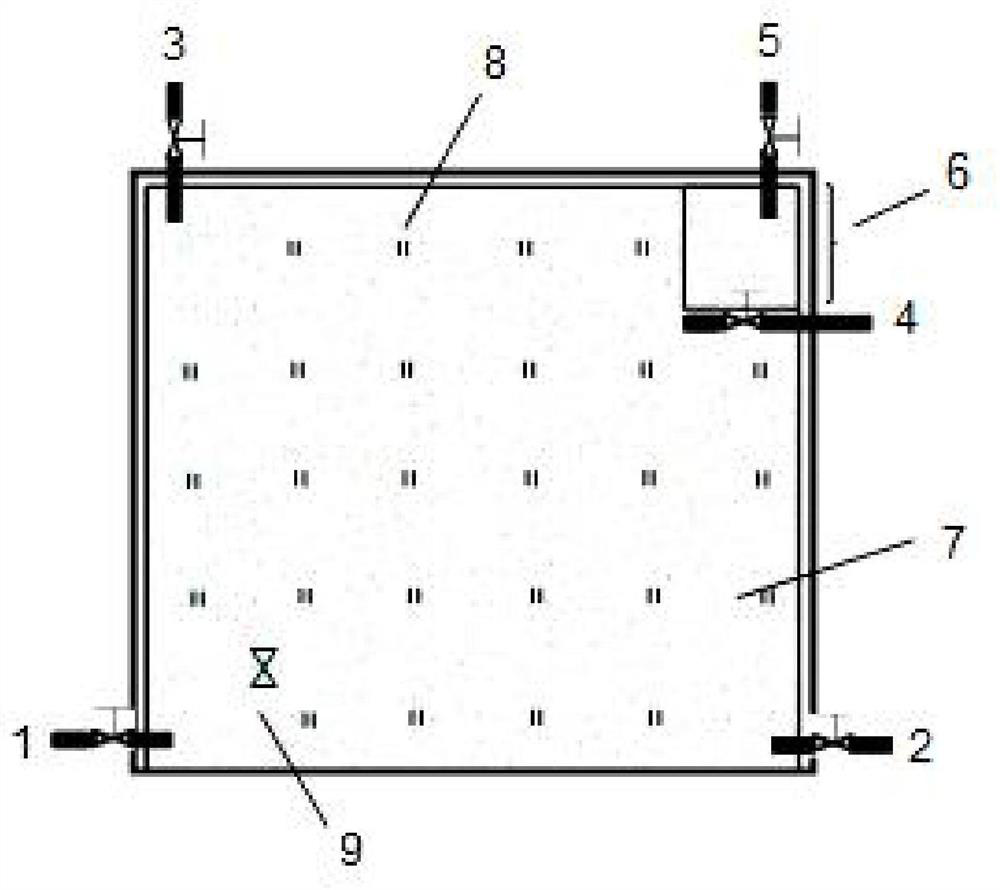

[0028] A chemical flooding injection well and production well plugging simulation device, the device is composed of a cube, the inside of the cube is filled with quartz sand, injection well simulation string 1, several production wellheads (including the first production well simulation string 2, The second production well simulation string 3, the third production well simulation string 4, and the plugged production well simulation string 5), and a saturation electrode 8 and a pressure sensor 9 are arranged in the horizontal direction.

[0029] The model body can use a sand-filled model or an artificial cemented model to complete the original porosity and permeability zone 7, and the filling material is quartz sand of a certain mesh.

[0030] The size of the model body is 30cm*30cm*4.5cm. Sand-filled models and artificial cemented models can be used to complete the original porosity and permeability zone 7. The filling material is quartz sand with a mesh size of 60-80 mesh. Th...

Embodiment 2

[0036] A method for using a chemical flooding injection well and production well plugging simulation device described in the above-mentioned embodiment 1, that is, a specific implementation process of a chemical flooding injection well and production well plugging simulation method is as follows:

[0037] 1. Model making: Fill the sand model or purchase the artificial cemented flat plate model according to the design plan and the actual situation of the blockage, and prepare according to the model instructions. First, choose 60-80 mesh quartz sand to arrange the original porosity and permeability area 7 and 100-120 mesh quartz sand to arrange the blockage area 6, and set 6*6 saturation electrodes 8 and pressure sensors 9 along the entire model in advance .

[0038] 2. The model simulates the one-injection and three-production well pattern of 1 / 4 anti-nine-point well group, and sets the injection well simulation string 1, the first production well simulation string 2, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com