Plasma torch having failure prediction function

A plasma and fault prediction technology, which is applied in the testing of plasma, measuring devices, machines/structural components, etc., can solve problems such as shortened life, delayed fault response, and inability to quickly respond to component faults, so as to prevent the expansion of the fault range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the plasma torch will be described in detail centering on examples with reference to the drawings of the present invention.

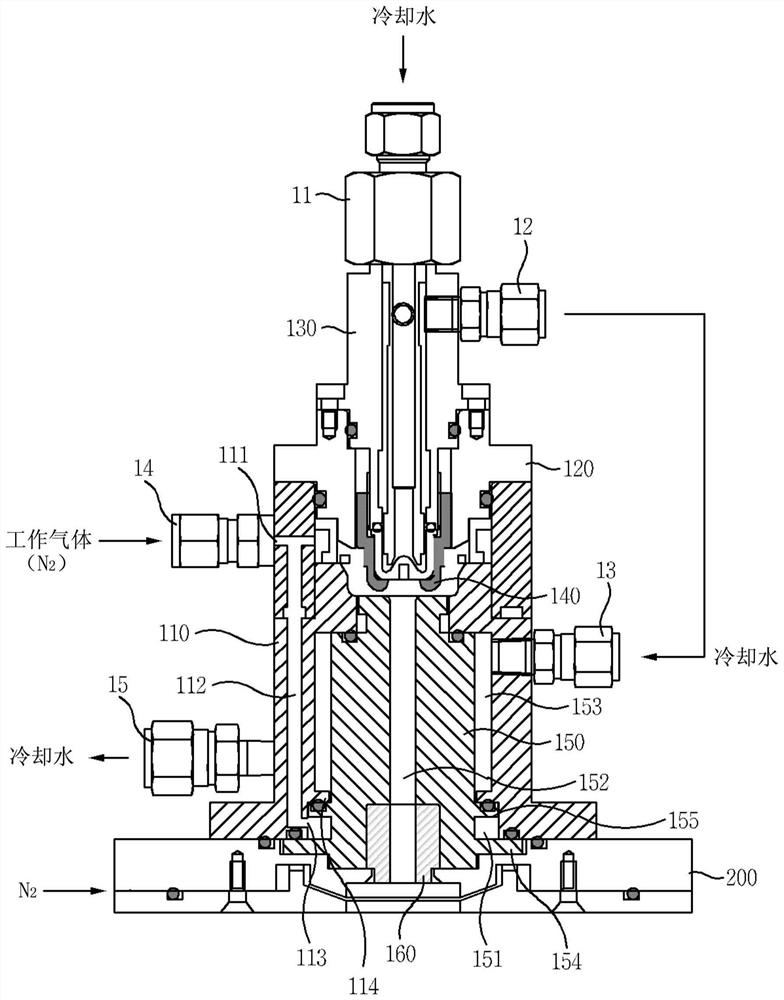

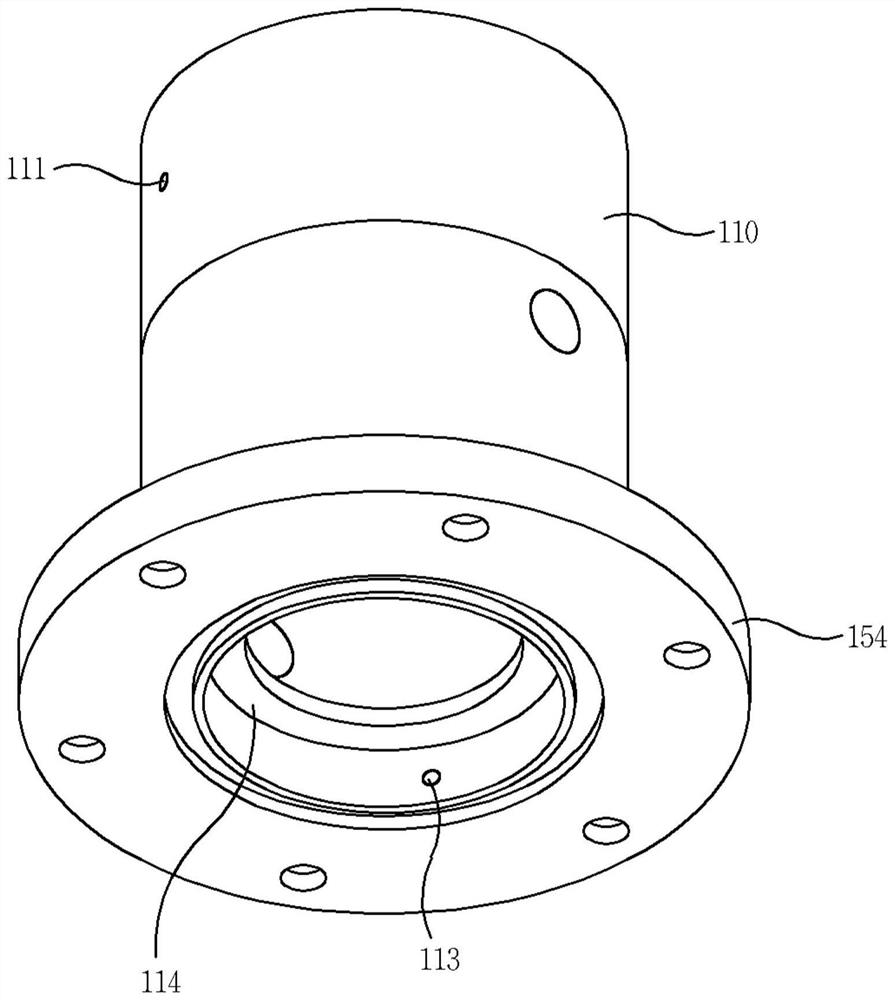

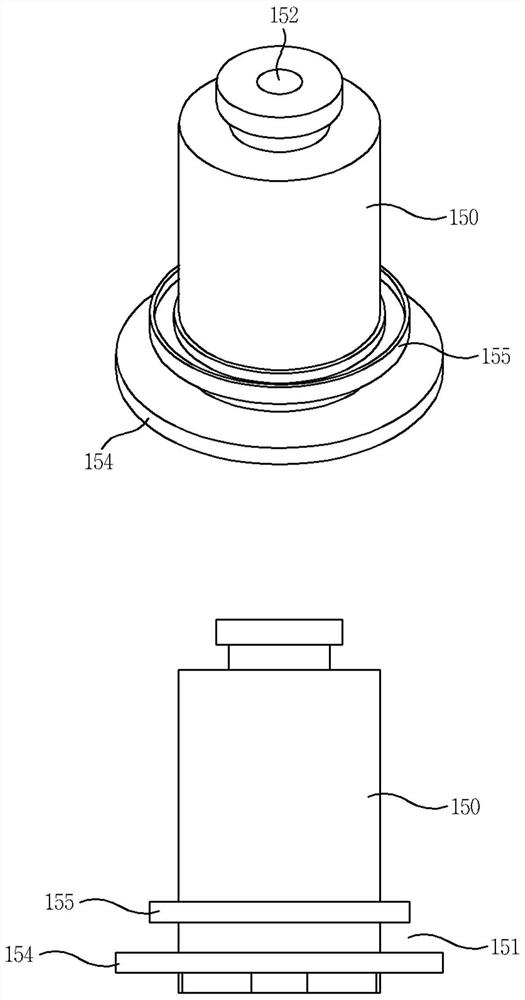

[0034] figure 1 represents a plasma torch according to an embodiment of the invention, figure 2 Indicates the body applied to the plasma torch, image 3 Indicates the anode applied to the plasma torch.

[0035] Since the arrangement of the body and cover, cathode and anode of a plasma torch is well known, it will be briefly described below.

[0036] Working gas (N 2 ) into the port 14, and the cooling water inflow port 13 and the outflow port 15 for cooling the anode 150 are respectively provided on opposite sides.

[0037] An insulating block 120 is interposed on the upper part of the main body 110 and a cover 130 is combined. An inflow port 11 and an outflow port 12 for inflow and outflow of cooling water for cooling the cathode 140 are respectively provided on the top and sides of the cover 130 .

[0038] Here, the cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com