Tangential rigidity measuring device for two crossed parabolic cylinders

A measuring device and technology of tangential stiffness, applied in the field of contact mechanics analysis and dynamics research, to achieve the effect of simple structure, easy measurement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

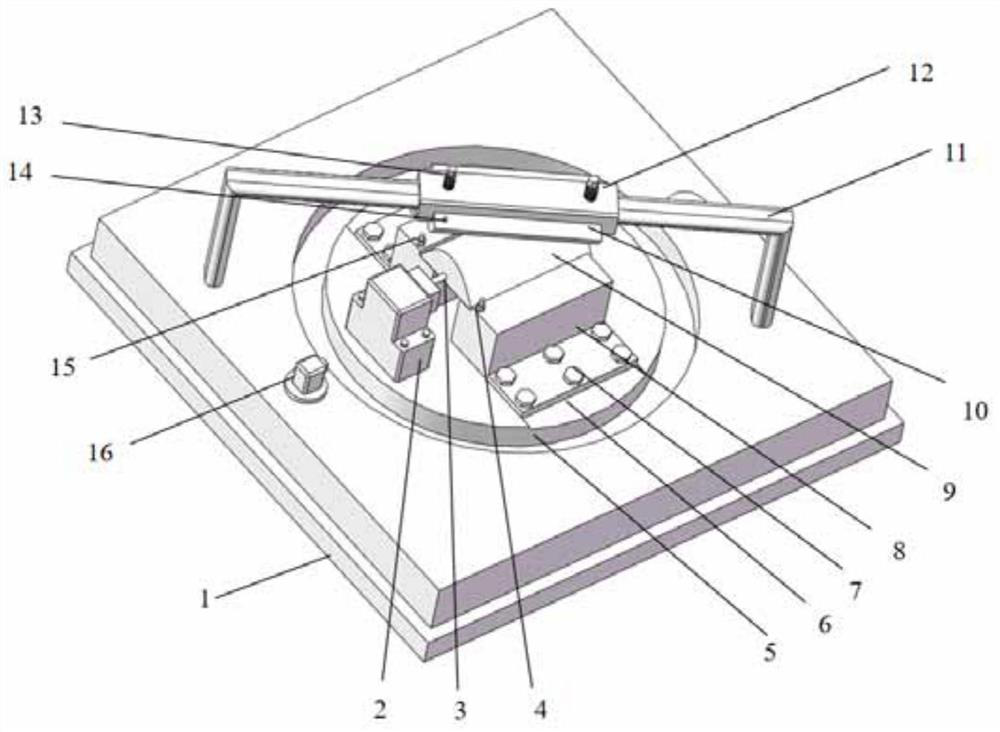

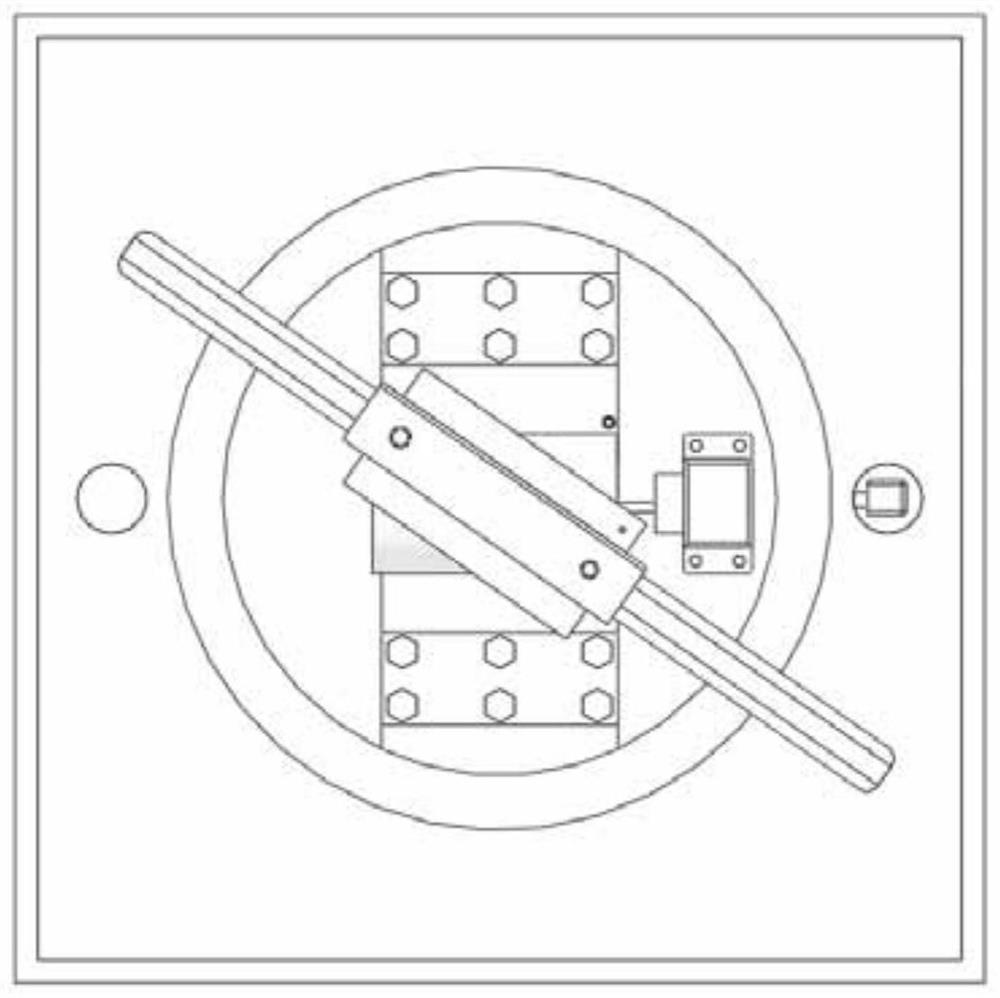

[0013] Referring to the accompanying drawings in the examples of the invention, the technical solutions in the present invention will be described completely and clearly.

[0014] Referring to the accompanying drawings, the present invention provides a device for measuring the tangential stiffness of two crossed parabolic cylinders: the device includes a rotating platform, an excitation device, a clamping device and a measuring device.

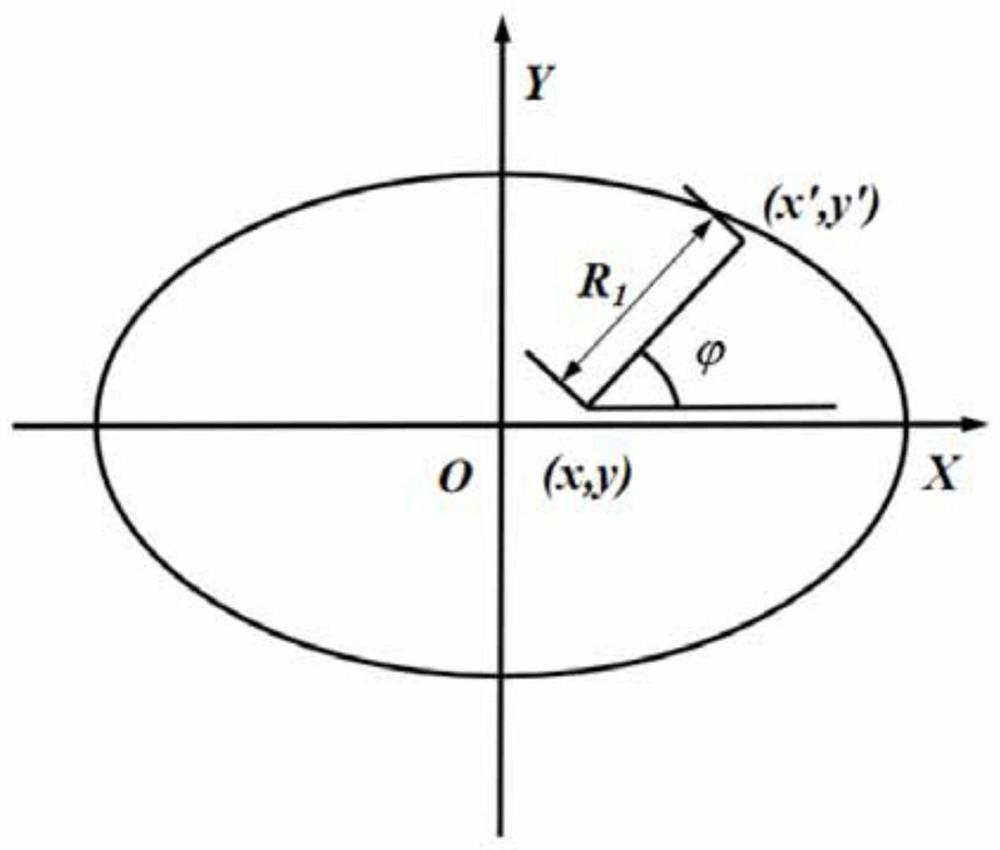

[0015] The entire measuring device is placed on the vibration-damping pad 1, and its purpose is to play a role of vibration-damping during the measurement process. The rotating platform 5 is driven by the geared motor 16 to move up and down and rotate, and adjust the axis crossing angle between the test pieces by rotating the lower test piece, so as to achieve the purpose of measuring the tangential stiffness of the test piece at different axis crossing angles. At the same time, the clamping device and the vibration device are placed on it, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com