Rod position system detection platform

A detection platform and rod position technology, applied in nuclear power generation, climate sustainability, nuclear reaction control, etc., can solve the problems of lack, complex rod position system function and structure, etc. The degree of knowledge and the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

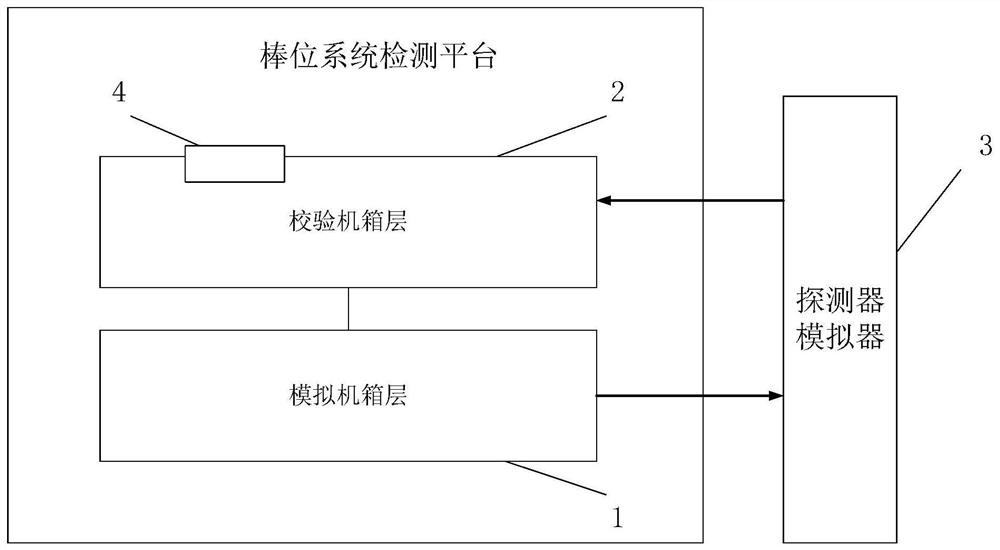

[0052] Please refer to figure 1 , which is a schematic structural diagram of the detection platform of the rod position system in this embodiment. Specifically, such as figure 1 As shown, the rod position system detection platform is connected to the detector simulator 3 in communication, and the rod position system detection platform includes a verification chassis layer 2 and a rod position logic simulation chassis layer 1 . The detector simulator 3 can simulate the on-site control rod position detector through the internal circuit, and generate corresponding rod position measurement signals, which can be used to realize the channel inspection and fault location diagnosis of the rod position system.

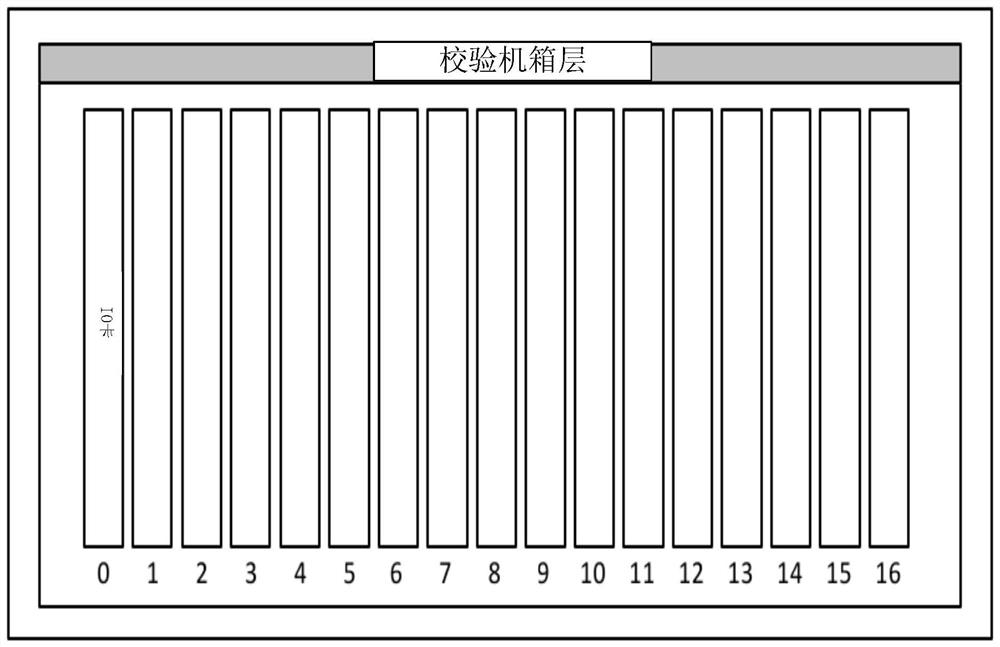

[0053] The verification chassis layer 2 includes a verification interface 4; the verification interface 4 is used to connect the components under test of the rod position system. The verification chassis layer is used to simulate the data acquisition cabinet of the rod positi...

Embodiment 2

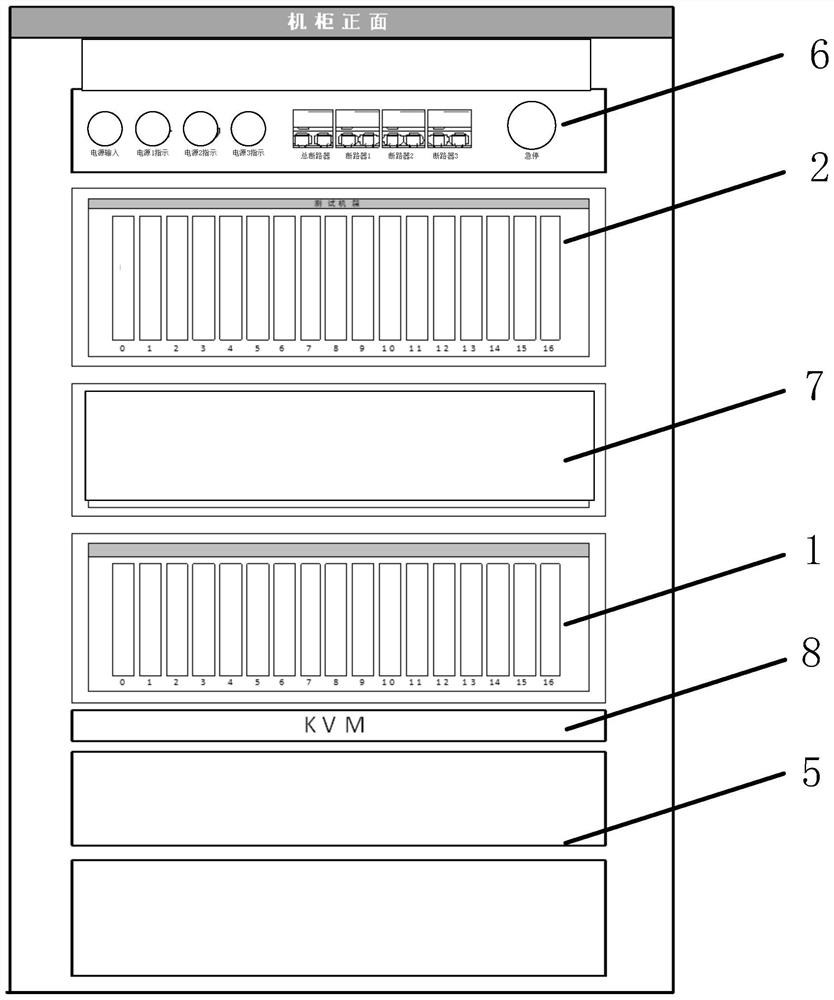

[0058] Such as figure 2 As shown, the rod position system detection platform of this embodiment is a further improvement to Embodiment 1, specifically:

[0059] In this embodiment, the rod position system testing platform further includes a DCS control cabinet; the verification chassis layer 2 and the rod position logic simulation chassis layer 1 are arranged in the DCS control cabinet.

[0060] Specifically, the rod position system detection platform uses DCS cabinet as the hardware environment, LABVIEW (a program development environment) as the development platform, and MySQL (a relational database management system) as the database server, mainly realizing data storage, management, display, etc. Features. It has security protection function and can set a login password to ensure that only legally authorized users can operate the device.

[0061] In an optional implementation manner, the component to be tested includes a coding card to be tested, an IO card to be tested, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com