Prefabricated embedded coil pipe composite ecological wall heat storage and release system

A heat storage and release, coil technology, applied in the heat storage system and energy saving field, can solve the problem of poor heat storage capacity of straw, and achieve the effect of reducing the heating time, wide application prospects, and promoting integrated development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention, and should not limit the protection scope of the present invention with this.

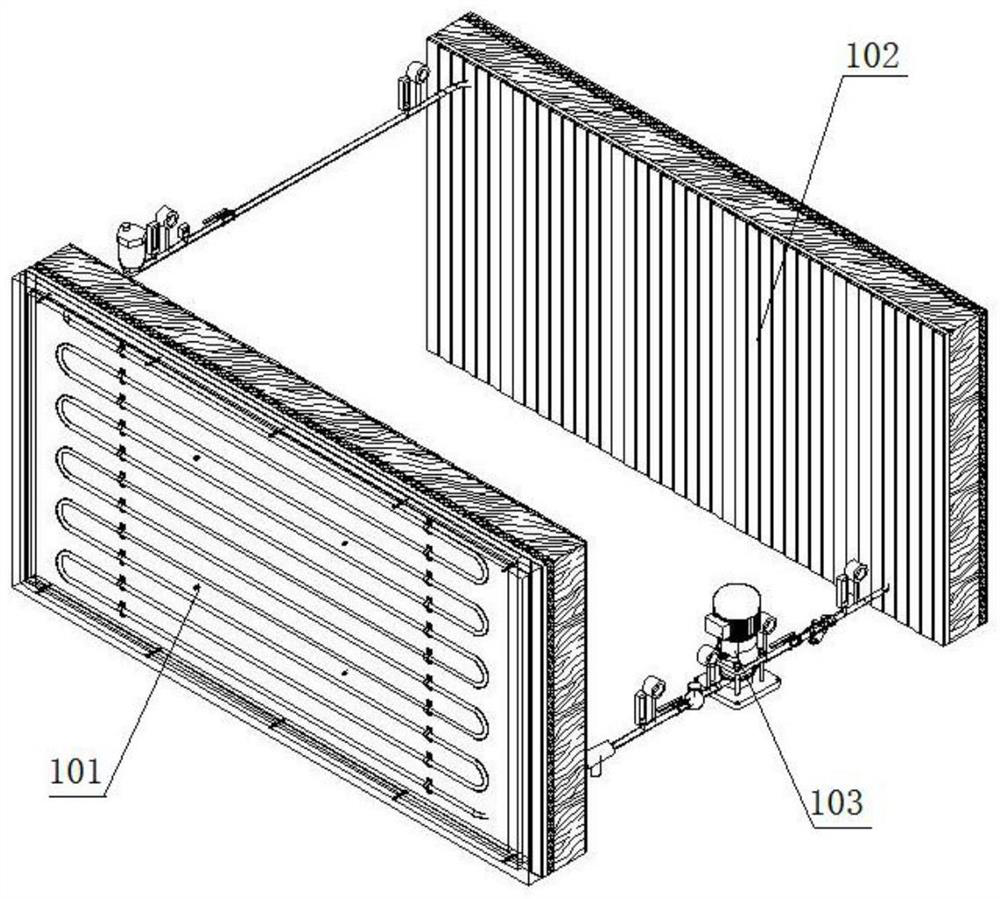

[0044] A prefabricated embedded coil composite ecological wall heat storage and release system, such as figure 1 As shown, it includes a heat collection module 101 on the south side, a heat release module 102 on the north side, and a pipeline flow system 103 .

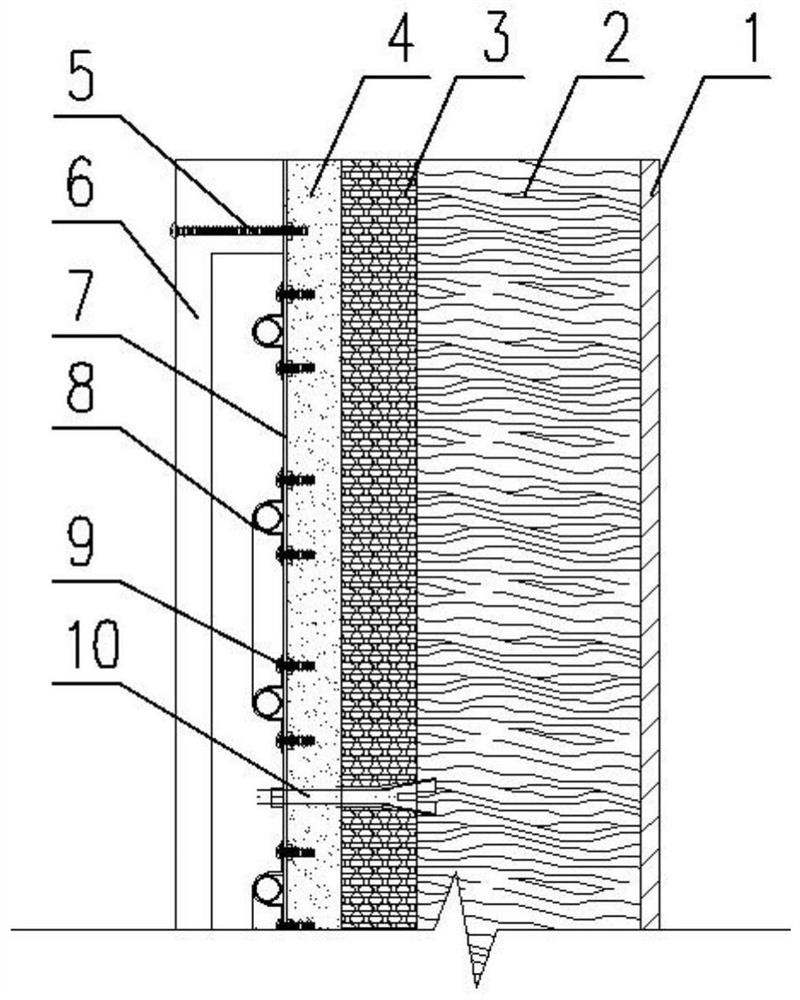

[0045] The heat collecting module 101 on the south side is as figure 2 As shown, it includes the south side decoration layer 1, the south side main wall 2, the south side insulation layer 3, the heat storage layer 4, the heat collection plate 7, the heat collection coil 8, and the PC board 6 arranged sequentially from inside to outside.

[0046] The manufacturing method of the south heat collecting module 101 is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com