A method, product, and application of a propylene production-increasing additive prepared by using a Fischer-Tropsch synthesis catalyst fine powder

A technology of Fischer-Tropsch synthesis and propylene additives, applied in the direction of carbon compound catalysts, catalysts, molecular sieve catalysts, etc., can solve the problem of underutilization and other problems, achieve the effect of saving treatment costs, eliminating solid waste, and extending the product chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

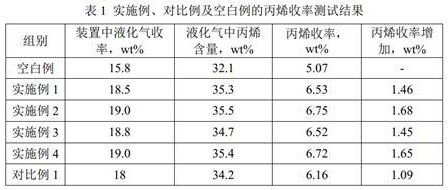

Examples

Embodiment 1

[0044] This embodiment provides a kind of preparation method of FCC production increasing propylene auxiliary agent, specifically comprises the following steps:

[0045] (1) Add 1600kg of deionized water, 425kg of silica sol, and 750kg of kaolin to the beating kettle successively, and stir for 30min;

[0046] (2) Add 500kg of deionized water and 315kg of phosphoric acid to the acid adding kettle successively, and stir for 10min;

[0047] (3) Add 700kg of deionized water and 820kg of ZSM-5 molecular sieve (dry basis) to the gelling kettle successively, and stir for 10 minutes;

[0048] (4) Add 300 kg of deionized water and 60 kg of Fischer-Tropsch synthesis catalyst fine powder to the auxiliary agent kettle successively, and stir for 10 min;

[0049] (5) Add the material described in step (2) to the beating kettle described in step (1), and stir for 30 minutes;

[0050] (6) Add the material obtained in step (3) into the beating kettle described in step (5), and stir for 60 min;...

Embodiment 2

[0056] This embodiment provides a kind of preparation method of FCC production increasing propylene auxiliary agent, specifically comprises the following steps:

[0057] (1) Add 1600kg of deionized water, 425kg of silica sol, and 750kg of kaolin to the beating kettle successively, and stir for 30min;

[0058] (2) Add 500kg of deionized water and 315kg of phosphoric acid to the acid adding kettle successively, and stir for 10min;

[0059] (3) Add 700kg of deionized water and 820kg of ZSM-5 molecular sieve (dry basis) to the gelling kettle successively, and stir for 10 minutes;

[0060] (4) Add 300kg of deionized water and 70kg of Fischer-Tropsch synthesis catalyst fine powder to the auxiliary agent kettle successively, and stir for 10min;

[0061] (5) Add the material obtained in step (2) to the beating kettle described in step (1), and stir for 30 minutes;

[0062] (6) Add the material obtained in step (3) into the beating kettle described in step (5), and stir for 60 min; ...

Embodiment 3

[0068] This embodiment provides a kind of preparation method of FCC production increasing propylene auxiliary agent, specifically comprises the following steps:

[0069] (1) Add 1600kg of deionized water, 425kg of silica sol, and 750kg of kaolin to the beating kettle successively, and stir for 30min;

[0070] (2) Add 500kg of deionized water and 315kg of phosphoric acid to the acid adding kettle successively, and stir for 10min;

[0071] (3) Add 700kg of deionized water and 820kg of ZSM-5 molecular sieve (dry basis) to the gelling kettle successively, and stir for 10 minutes;

[0072] (4) Add 300kg of deionized water and 80kg of Fischer-Tropsch synthesis catalyst fine powder to the auxiliary agent kettle successively, and stir for 10min;

[0073] (5) Add the material obtained in step (2) to the beating kettle described in step (1), and stir for 30 minutes;

[0074] (6) Add the material obtained in step (3) into the beating kettle described in step (5), and stir for 60 min; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com