Aircraft engine fan blade cleaning and lubricating system

A technology of aircraft engine and fan blades, which is applied in the direction of engine lubrication, engine components, wind power generation, etc., can solve problems such as damage to human health, poor cleaning effect, and high labor intensity, so as to liberate manpower and achieve good cleaning and lubrication effects , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

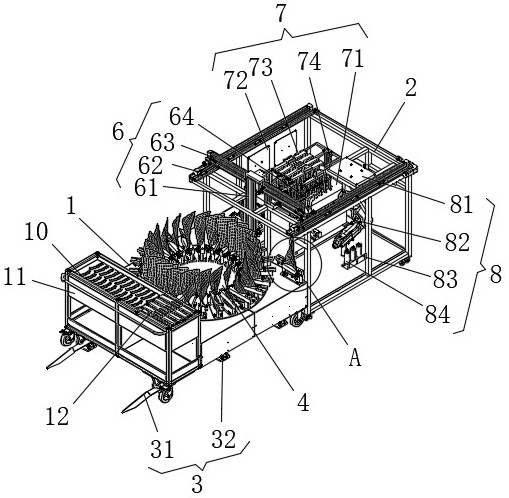

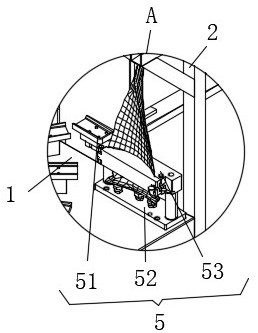

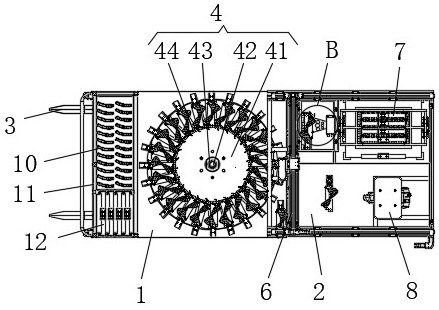

[0025] Such as Figure 1-Figure 4 A kind of aircraft engine fan blade cleaning and lubricating system shown, comprises blade storage car 1 and the cleaning and lubricating equipment 2 that blade storage car 1 side is arranged, and the upper surface of blade storage car 1 is provided with storage device 4, and blade storage car 1 The lower surface is provided with a positioning mechanism 3, the right side of the upper surface of the blade storage vehicle 1 is provided with a loading and unloading station 5, the upper surface of the cleaning and lubricating equipment 2 is provided with a mobile robot 6, and the cleaning and lubrication equipment 2 is close to the blade storage vehicle 1. A mechanical cleaning station 9 is arranged on one side, an ultrasonic cleaning station 7 is installed in the cleaning and lubricating equipment 2, and a lubricating station 8 is arranged in the cleaning and lubricating equipment 2.

[0026] When in use, the operator first transports the disasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com