Six-degree-of-freedom control mechanical arm

A technology of robotic arms and degrees of freedom, applied in the field of robotic arms, can solve the problems of restricting the working range of robotic arms, unfavorable work, and small range of activities, and achieve the effects of facilitating construction processing, improving practicability, and expanding working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

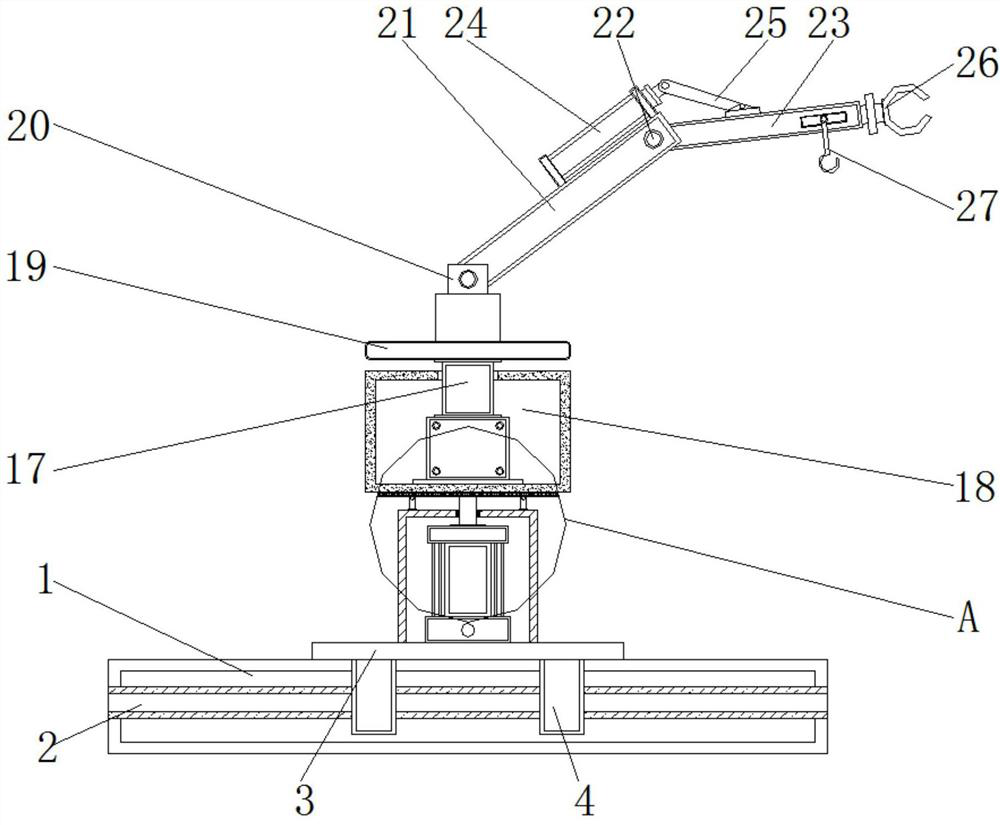

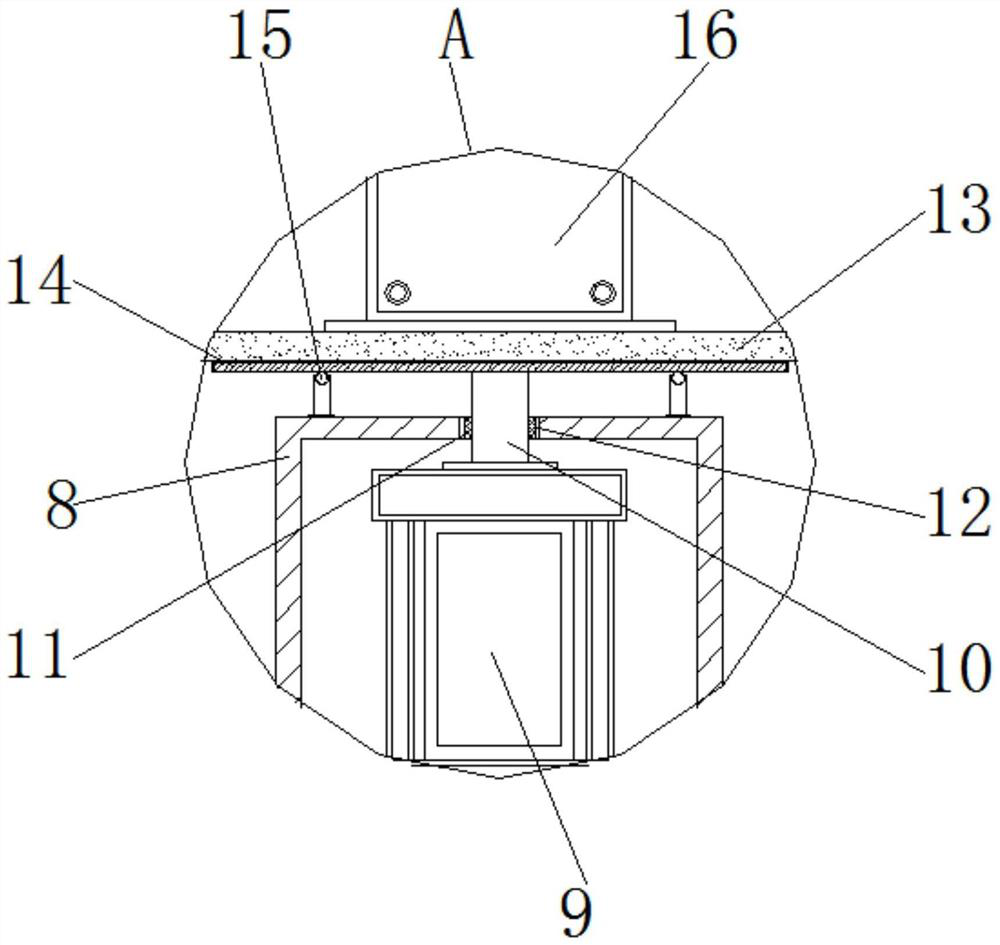

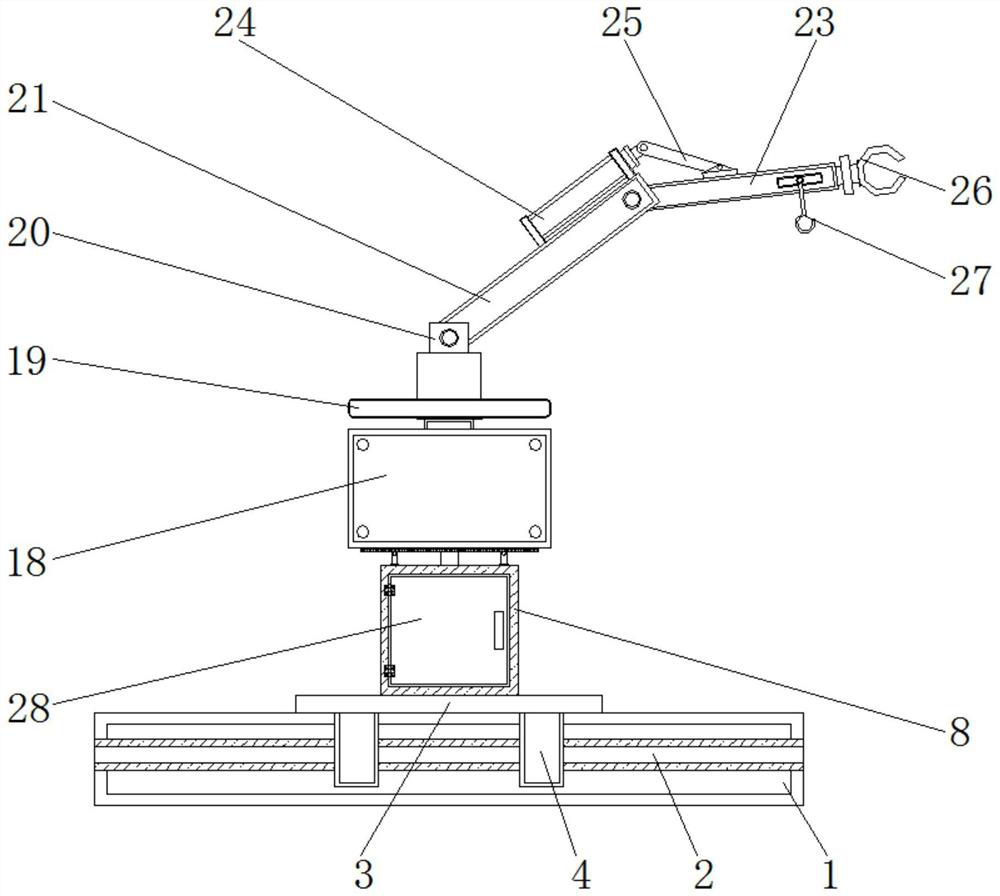

[0021] Please refer to figure 1 , figure 2 and Figure 4 As shown, the present invention provides a technical solution: a six-degree-of-freedom control mechanical arm, including a fixed base 1 and a motor 9, slide rails 2 are installed on both sides of the fixed base 1, and the slide rails 2 are arranged along the sides of the fixed base 1. The vertical center line is symmetrically distributed, and the slide rail 2 and the fixed seat 1 are vertically distributed. The top of the fixed seat 1 is equipped with a moving plate 3, and the bottom of the moving plate 3 is connected with a side plate 4, and the side plate 4 passes through the card. The block 5 forms a sliding connection with the slide rail 2, and the inner diameter of the side plate 4 is adapted to the outer diameter of the block 5. The inner side of the side plate 4 is connected with the block 5, and the bottom of the moving plate 3 is connected with a Ball 6, and the outer side of ball 6 is distributed with chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com