Tower crane upper structure and flat-top tower crane

A technology for tower cranes and hoisting mechanisms, applied in cranes and other directions, can solve the problems of inconvenient transportation, large size of the balance arm, easy inclination of the bottom surface when disassembled and placed, and achieves easy transportation and disassembly, reduced structural size, and obvious safety and reliability. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

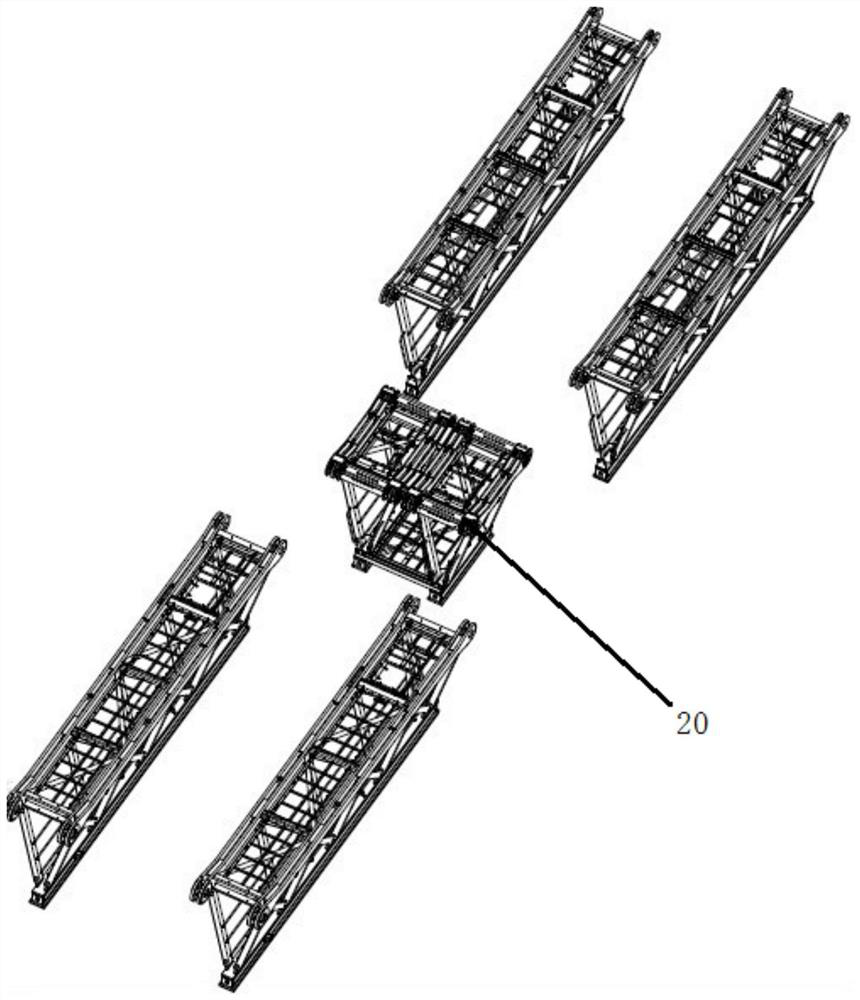

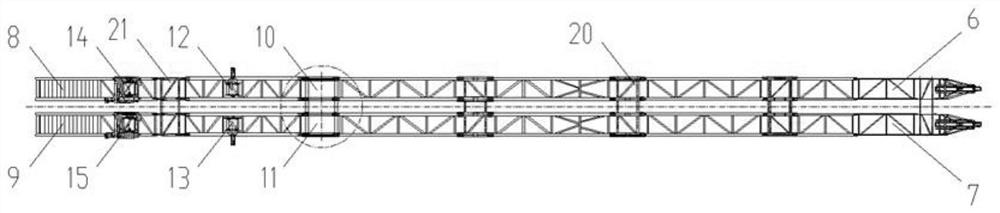

[0045] Such as Figure 1 to Figure 3 , In this embodiment, a tower crane superstructure is provided, which specifically includes: a lifting arm 1 , a tower top 2 , and a balance arm 3 . Among them, boom 1 is divided into: left boom 6, right boom 7; tower top 2 is divided into: left tower top 10, right tower top 11; balance arm 3 is divided into: left balance arm 8, right balance arm 9; left luffing mechanism 12 and left lifting mechanism 14 are arranged on the left balance arm 8; right luffing mechanism 13 and right lifting mechanism 15 are arranged on the right balance arm 9; left trolley 22 and The left hook pulley block 16; the right boom 7 is provided with a right trolley 23 and a right hook pulley block 17; the left hook pulley block 16, the right hook pulley block 17, the balance beam 18, and the hook head 19 jointly form a large hook block 24 .

[0046] The boom 1 is made up of two boom frames on the left and right, which can make the trolley walk on the boom to carry...

Embodiment 2

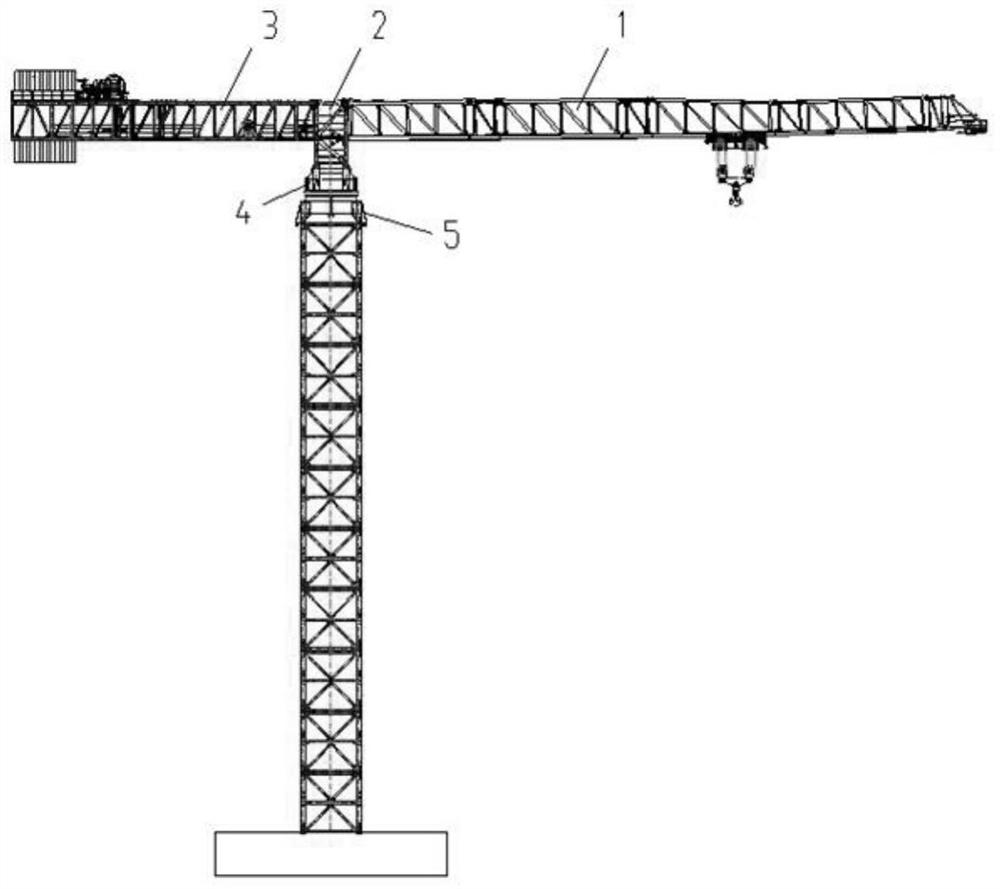

[0067] Such as Figure 4 As shown, in this embodiment, a flat-top tower crane is provided, including the tower crane superstructure in Embodiment 1, and also includes an upper support 4 and a lower machine 5

[0068] The upper support 4 is connected to the top of the tower, and the lower part is connected to the lower machine 5 through a slewing bearing, and a mechanism for driving rotation is installed inside so that the upper machine of the tower crane can rotate freely. Get off the machine 5: set up the upper structure so that the tower crane has a certain lifting height.

[0069] The upper structure of the tower crane and the flat-top tower crane provided by this application: the boom of the smaller tower crane is connected in parallel left and right through a number of boom joints to form the boom of the large tower crane, and the balance of the smaller tower crane The arms are connected in parallel left and right through a number of balance arm joints to form the balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com