Dual-phase heterogeneous light-weight high-strength steel and preparation method thereof

A technology of high-strength steel and high-strength steel plate, which is applied in the field of dual-phase heterogeneous light-weight high-strength steel and its preparation, can solve the problem of deterioration of strength and toughness, weldability, density and rust resistance of light-weight high-strength steel for automobiles, and high cost of alloying element addition. , the preparation process is complicated and other problems, to achieve the effect of light weight, increase strong plastic product, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

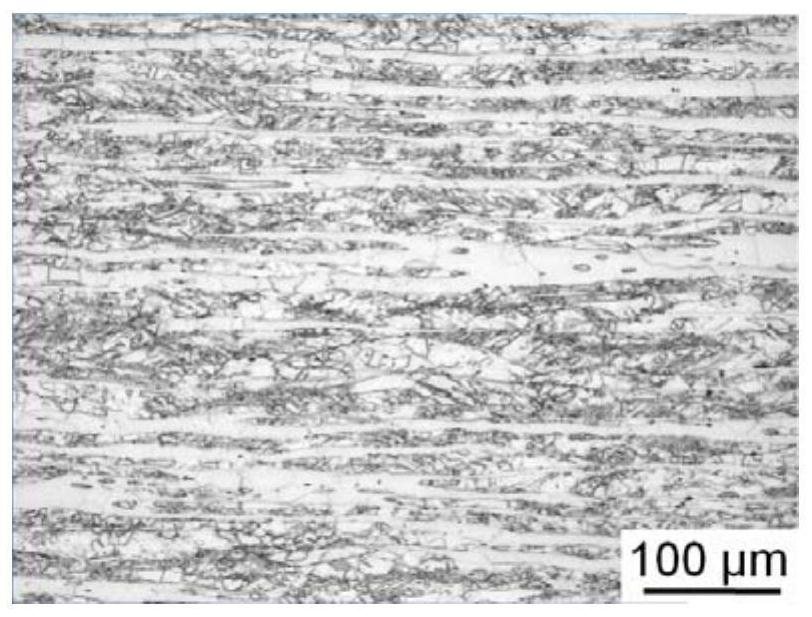

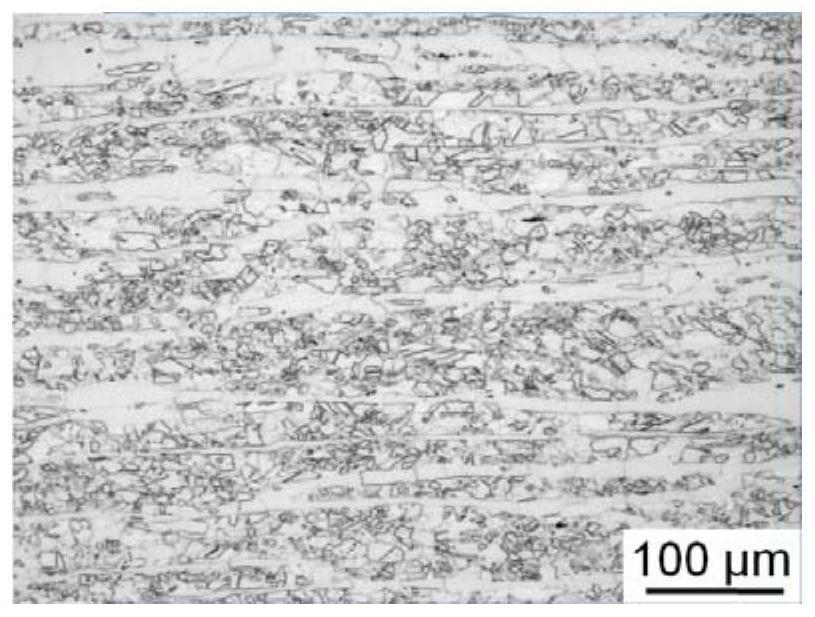

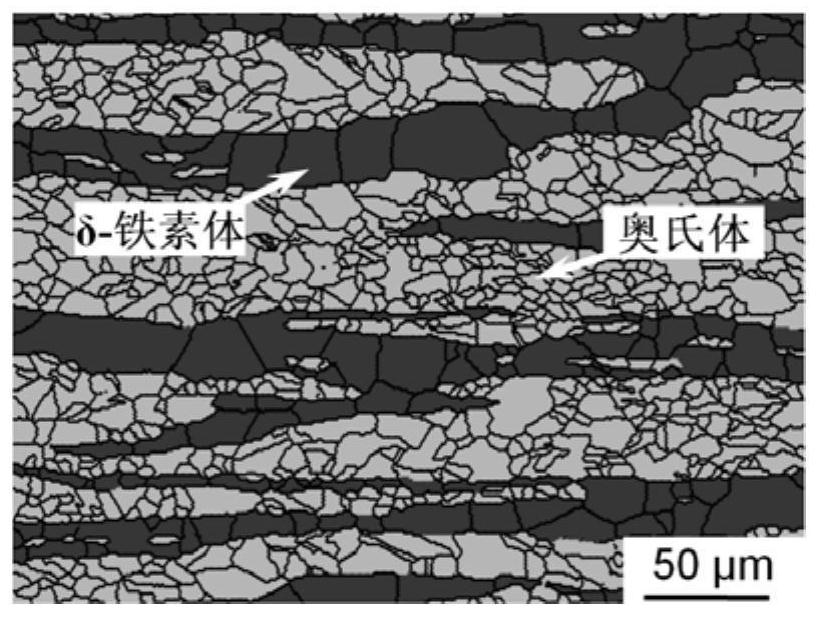

Image

Examples

Embodiment 1

[0039] A dual-phase heterogeneous lightweight high-strength steel, the chemical composition of which is calculated by mass percentage: C 0.14wt.%, Mn13.9wt.%, Al 6.1wt.%, Si 0.68wt.%, P≤0.01wt.% , S≤0.005wt.%, the rest is Fe and unavoidable impurities.

[0040] The preparation method of the dual-phase heterogeneous light-weight high-strength steel, the preparation method includes the following steps:

[0041] S1. Raw material selection: Weigh Fe, Mn, C, Al, Si powders with purity ≥ 99.9% according to the chemical composition ratio of the dual-phase heterogeneous light-weight high-strength steel as alloy raw materials, and put the alloy raw materials into the electric In the magnetic induction furnace, vacuum melting is carried out under the protection of argon, and then the molten steel is cast into ingots;

[0042] S2. Hot forging after homogenization treatment: homogenize the ingot described in step S1, the temperature of the homogenization treatment is 1200±30°C, and the hol...

Embodiment 2

[0049] A dual-phase heterogeneous lightweight high-strength steel, the chemical composition of which is calculated by mass percentage: C 0.22wt.%, Mn12.1wt.%, Al 7.2wt.%, Si 0.63wt.%, P≤0.01wt.% , S≤0.005wt.%, the rest is Fe and unavoidable impurities.

[0050] The preparation method of the dual-phase heterogeneous light-weight high-strength steel, the preparation method includes the following steps:

[0051] S1. Raw material selection: Weigh Fe, Mn, C, Al, Si powders with purity ≥ 99.9% according to the chemical composition ratio of the dual-phase heterogeneous light-weight high-strength steel as alloy raw materials, and put the alloy raw materials into the electric In the magnetic induction furnace, vacuum melting is carried out under the protection of argon, and then the molten steel is cast into ingots;

[0052] S2. Hot forging after homogenization treatment: homogenize the ingot described in step S1, the temperature of the homogenization treatment is 1200±30°C, and the h...

Embodiment 3

[0059] A dual-phase heterogeneous lightweight high-strength steel, the chemical composition of which is calculated by mass percentage: C 0.28wt.%, Mn10.1wt.%, Al 8.1wt.%, Si 0.55wt.%, P≤0.01wt.% , S≤0.005wt.%, the rest is Fe and unavoidable impurities.

[0060] The preparation method of the dual-phase heterogeneous light-weight high-strength steel, the preparation method includes the following steps:

[0061] S1. Raw material selection: Weigh Fe, Mn, C, Al, Si powders with purity ≥ 99.9% according to the chemical composition ratio of the dual-phase heterogeneous light-weight high-strength steel as alloy raw materials, and put the alloy raw materials into the electric In the magnetic induction furnace, vacuum melting is carried out under the protection of argon, and then the molten steel is cast into ingots;

[0062] S2. Hot forging after homogenization treatment: homogenize the ingot described in step S1, the temperature of the homogenization treatment is 1200±30°C, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com