Corrosion and scale inhibitor for oil and gas gathering and transportation and preparation method of corrosion and scale inhibitor

A corrosion and scale inhibitor, oil and gas gathering and transportation technology, applied in the field of corrosion and scale inhibitors, can solve the problems of poor scale and corrosion inhibition effects, and achieve the reduction of calcium phosphate deposition, environmental friendliness, and scale inhibition effect significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

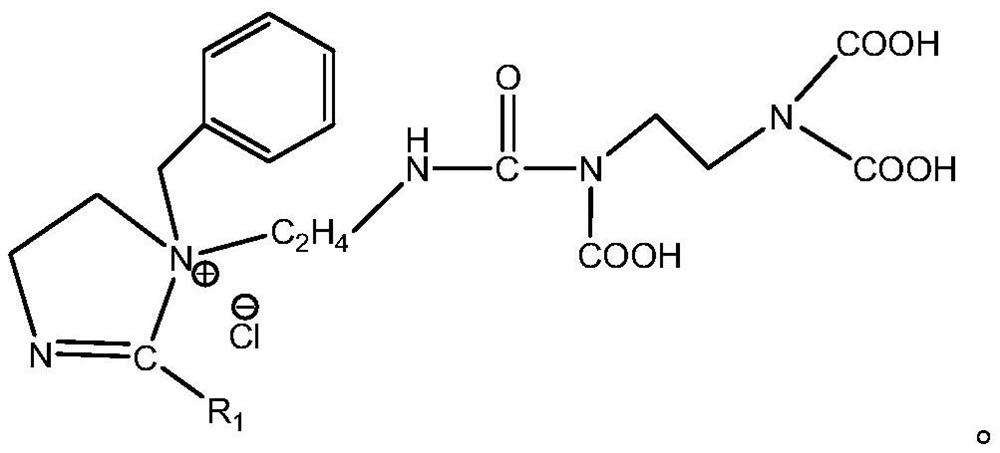

[0031] This example provides a corrosion and scale inhibitor for oil and gas gathering and transportation. The corrosion and scale inhibitor is composed of component A, which is prepared from the following raw materials: 0.1mol oleic acid, 0.15mol diethylenetriamine, 0.11mol EDTA, 0.102mol benzyl chloride.

[0032] The preparation method of A component comprises the steps:

[0033] Add 0.1mol oleic acid into the three-necked flask, start heating the three-necked flask with a heating mantle, and stir while heating until the oleic acid is completely dissolved;

[0034] After continuing to heat up to 160°C, slowly add 0.15mol of diethylenetriamine dropwise, and react at 160°C for 2 hours;

[0035] Then add 40ml of xylene and heat up to 220°C, use a water separator to continuously remove the water until no xylene and water are evaporated, and carry out the cyclization reaction at 220°C for 2 hours to obtain the first intermediate product;

[0036] Cool the first intermediate pro...

Embodiment 2

[0043] This example provides a corrosion and scale inhibitor for oil and gas gathering and transportation, the corrosion and scale inhibitor is composed of A component and B component, and the weight ratio of A component and B component is: 9:1; wherein, The raw material composition and preparation method of component A are the same as those in Example 1, and will not be repeated here.

[0044] Component B includes the following parts by weight:

[0045] 10 parts of sodium ethylenediamine tetramethylene phosphonate;

[0046] 25 parts of zinc chloride;

[0047] 65 parts of deionized water.

[0048] The preparation method of component B is as follows: uniformly mix a certain proportion of sodium ethylenediamine tetramethylene phosphonate, zinc chloride and deionized water.

[0049] When using, mix component A and component B according to 9:1.

Embodiment 3

[0051] This example provides a corrosion and scale inhibitor for oil and gas gathering and transportation, the corrosion and scale inhibitor is composed of A component and B component, and the weight ratio of A component and B component is: 8:2; wherein, The raw material composition and preparation method of component A are the same as those in Example 1, and will not be repeated here.

[0052] Component B includes the following parts by weight:

[0053] 15 parts of sodium ethylenediamine tetramethylene phosphonate;

[0054] 20 parts of zinc sulfate;

[0055] 65 parts of deionized water.

[0056] The preparation method of component B is as follows: uniformly mix a certain proportion of sodium ethylenediamine tetramethylene phosphonate, zinc sulfate and deionized water.

[0057] When using, mix component A and component B according to 8:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com