Oil extraction process method for heavy oil well

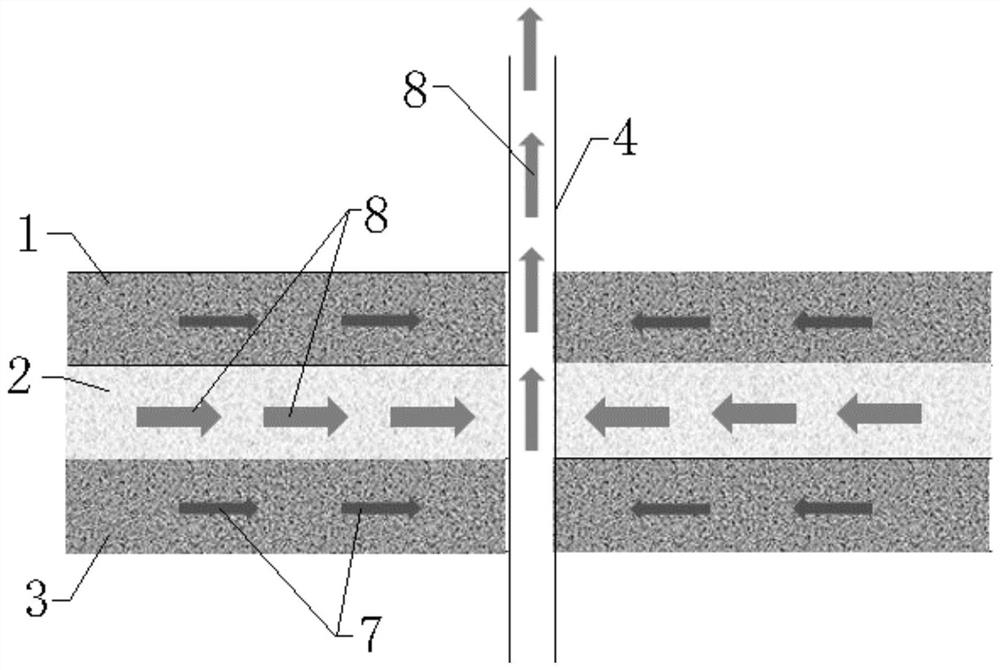

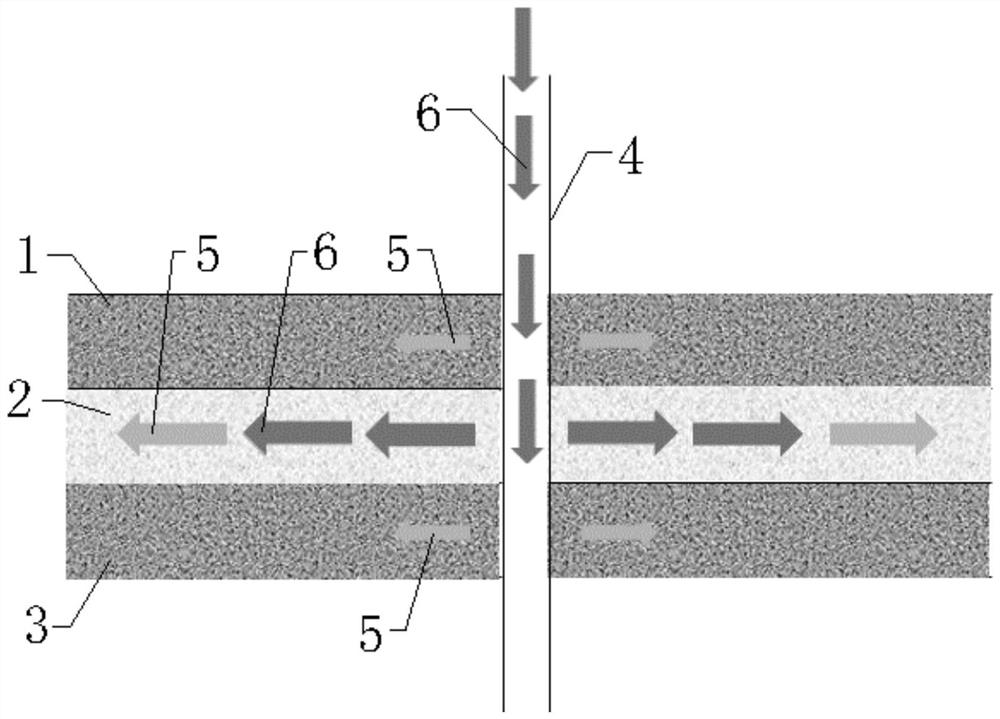

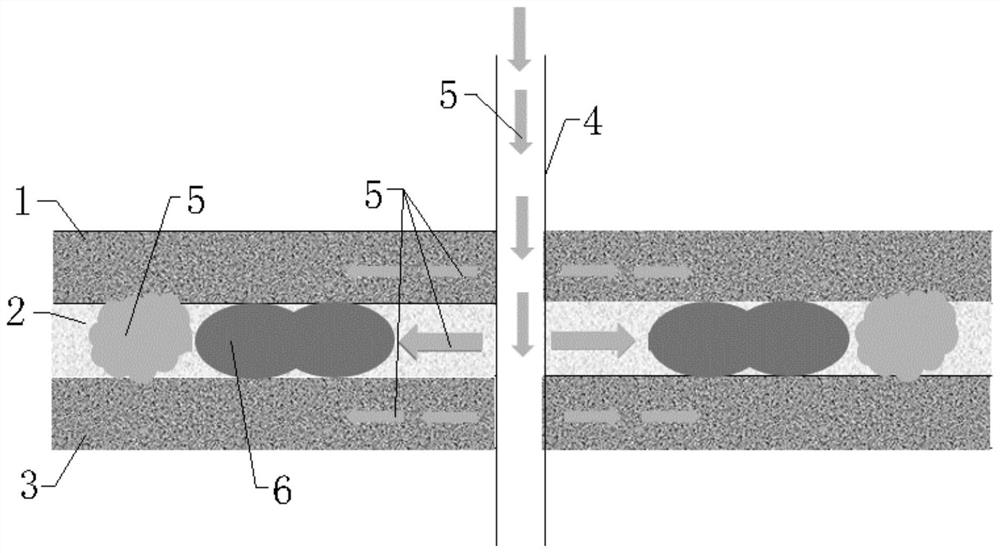

A technology for heavy oil reservoirs and oil production wells, which is applied in the field of conventional heavy oil wells in the field of conventional heavy oil wells to reduce viscosity, blockage, adjust and increase efficiency, and can solve problems such as uneven water injection effects, increased water injection production costs, and high construction risks. The effect of uneven water injection effect, reduction of water flooding production cost, and broad prospect of technology market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The oil well described in this embodiment is a directional well, the crude oil viscosity of this well is 8000mPa.s (according to GB / T265-1988 standard), and the crude oil density is 0.94g / cm 3 , the colloidal asphaltene content is 37wt.%, the wax content is 6.68wt.%, the oblique thickness of the oil layer is 46.3m, the vertical thickness is 23.1m, the average porosity of the reservoir is 29.8%, and the target formation from 3352.8m to 3492.6m can be regarded as Oil layer 1, oil layer 2 and oil layer 3, among them, 3352.8m to 3393m can be regarded as oil layer 1 with a permeability of 38mD and a vertical thickness of 9.2m; 3402.5m to 3418.9m can be regarded as oil layer 2 with a permeability of 1056mD and a vertical thickness of 3.1m ; 3424.7 to 3492.6m can be regarded as oil layer 3, the permeability is 51mD, the vertical thickness is 10.8m, the water content of the well is 94.2%, and the daily oil production is 20m 3 / d, recovery degree 15.5%;

[0063] The first fluid...

Embodiment 2

[0078] The oil well described in this embodiment is another directional well different from that of Embodiment 1, the crude oil viscosity of this well is 9500mPa.s, and the crude oil density is 0.95g / cm 3 , the colloidal asphaltene content is 39wt.%, and the wax content is 7.68wt.%. Compared with Example 1, the crude oil viscosity, density, colloidal asphaltene content and wax content of this well are higher, and the oblique thickness of the oil layer is 55.9 m, vertical thickness 37.1m, average reservoir porosity 30.5%, target formations from 3766.2m to 3961.9m can be regarded as oil layer 1, oil layer 2 and oil layer 3, 3766.2m to 3846.7m can be regarded as oil layer 1, and the permeability is 60mD , the vertical thickness is 19.2m; 3859.6m to 3884.1m can be regarded as the oil layer 2, the permeability is 1700mD, and the vertical thickness is 3.5m; 3888.6 to 3961.9m can be regarded as the oil layer 3, the permeability is 79mD, and the vertical thickness is 14.4m, and the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com