Double-half inner ring angular contact ball bearing with radial load larger than axial load

A technology of angular contact ball bearings and double-half inner rings, which is applied in the direction of rolling contact bearings, ball bearings, shafts and bearings, and can solve the problem that the axial load capacity of deep groove ball bearings cannot meet the requirements and cannot meet the requirements of aero-engine accessory transmission bearings Speed and other issues, to achieve good working condition, optimize groove curvature coefficient, improve the effect of axial bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

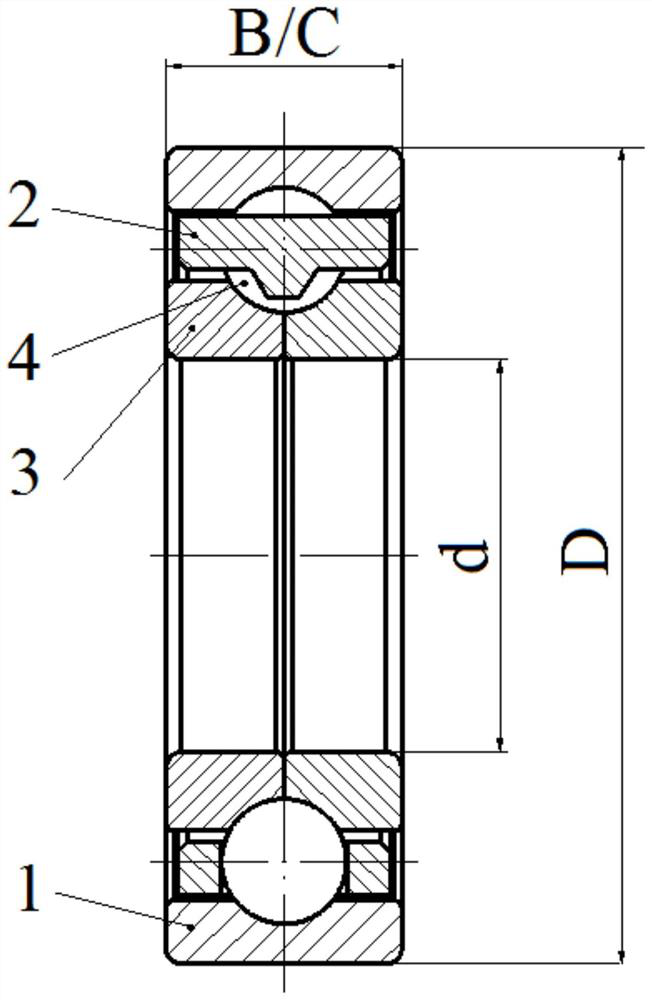

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment, a double-half inner ring angular contact ball bearing in which the radial load is greater than the axial load. The double-half inner ring angular contact ball bearing includes an outer ring 1, a cage 2, two halves Inner ring 3 and multiple rolling elements 4, two and a half inner rings 3 are coaxially arranged inside outer ring 1, cage 2 is set on two half inner rings 3, and cage 2 is located outside two half inner rings 3 In the middle part, a plurality of rolling elements 4 are installed in the plurality of pockets of the cage 2, and the two and a half inner rings 3 adopt a gasket angle of 0-8°.

[0022] The double-half inner ring of the bearing in this embodiment adopts a gasket angle design of 0-8°, optimizes the curvature coefficient of the groove, meets the requirements of the radial load working condition of the bearing, improves the axial bearing capacity of the bearing, and satisfies t...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 Describe this embodiment, the inner diameter of the double-half inner ring angular contact ball bearing in this embodiment is d, where d=25mm, the outer diameter is D, where D=52mm, and the width is B / C, where B / C=15mm. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the material of the outer ring 1 and the two half inner rings 3 of the double-half inner ring angular contact ball bearing of this embodiment is double vacuum Cr4Mo4V steel. Such setting can meet the requirements of the bearing working temperature of -40 to +250°C. At the same time, the material also needs to have stable hardness, strength, good wear resistance and high fracture toughness at high temperatures. The material of the bearing ring adopts double vacuum Cr4Mo4V steel, which has good wear resistance and high temperature dimensional temperature resistance, and can be used up to 310 °C, and the operating temperature margin meets the requirements. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com