Variable-size tetrahedron unit lattice structure and preparation method thereof

A technology of lattice structure and tetrahedron, which is applied in the direction of additive manufacturing, building components, process efficiency improvement, etc., can solve the problem of fully enhancing the mechanical properties of lattice type-related structures, poor external load capacity of lattice structures, quality and elasticity Problems such as large modulus, to achieve less waste of time and economic costs, increase flexibility and freedom, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

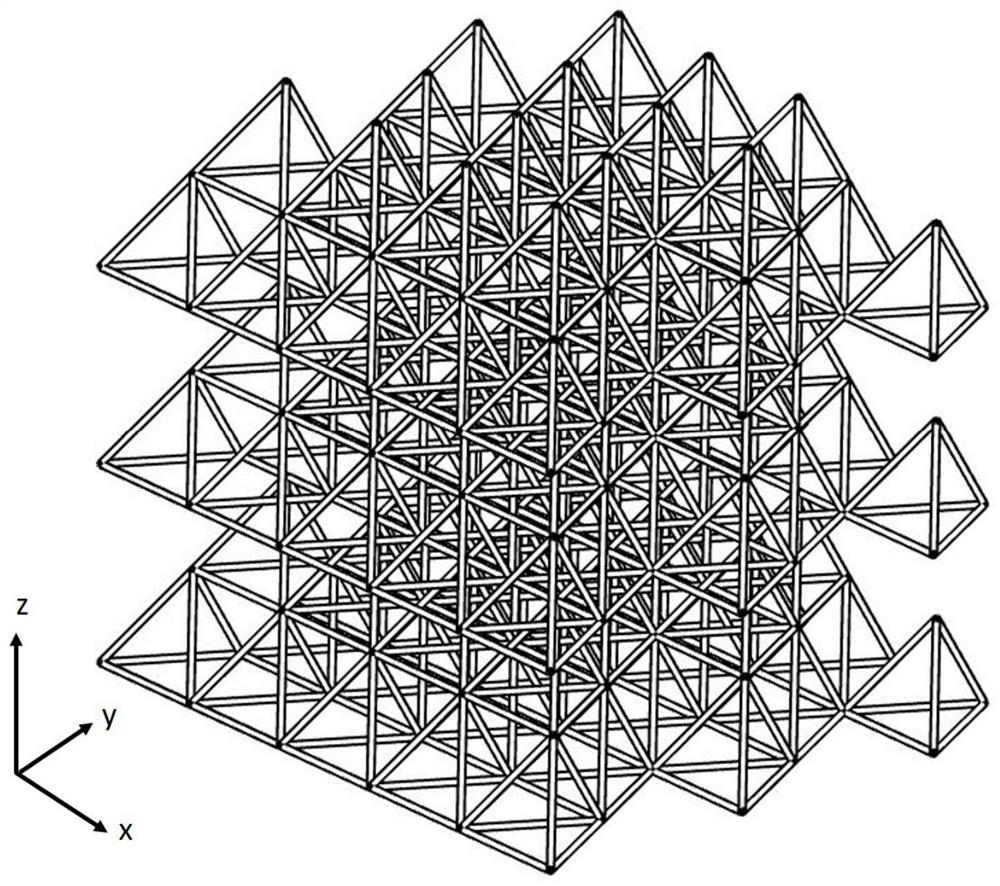

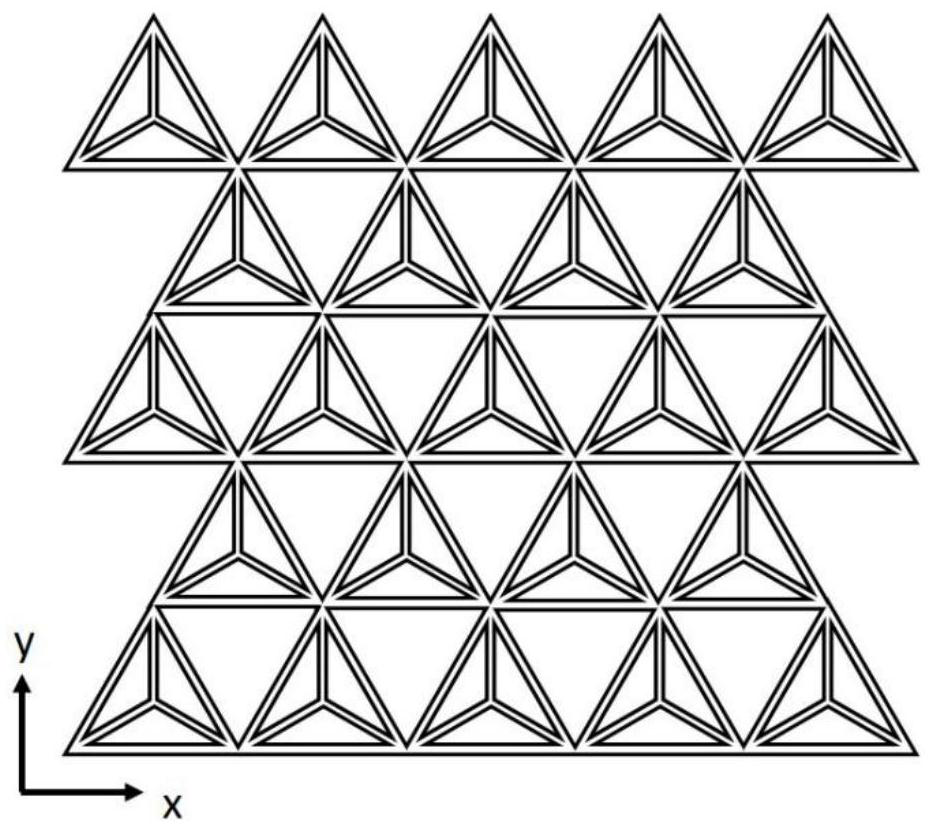

[0038] see figure 1 and figure 2 , the present embodiment provides a lattice structure of variable-size tetrahedral units, which is characterized in that it includes a plurality of variable-size tetrahedral units arranged in space, and the variable-size tetrahedral units are composed of six variable-section edge rods connected to each other. The diameter of the cross-section edge rod increases or decreases continuously and gradually, and any two adjacent variable-size tetrahedral units share a variable-section edge rod, and its spatial arrangement is the stacking expansion of multiple variable-size tetrahedral units , to form a plurality of lattice layers vertically distributed, and adjacent lattice layers are connected to each other.

Embodiment 2

[0040] On the basis of the foregoing embodiments, the tetrahedron unit is a regular tetrahedron, and the lengths of the six variable-section edge rods are all equal. When the tetrahedron unit is a regular tetrahedron, and the length of the variable-section edge rod is set to be a , then the height of the variable-size tetrahedral element is

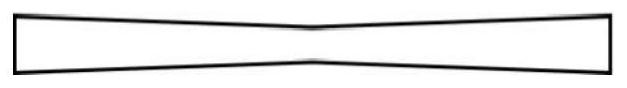

[0041] see image 3 and Figure 4 , the variable section edge rod is a symmetrical positive gradient edge rod or a symmetrical negative gradient edge rod, and the symmetrical positive gradient edge rod is a symmetrical edge with the largest radial dimension at both ends and the smallest radial dimension in the middle section Rods; symmetrical negative gradient edge rods are edge rods with the smallest radial dimension at both ends and the largest radial dimension in the middle section and are symmetrical; these two types of edge rods can deal with different deformations under different stress conditions In some cases, the deformation ...

Embodiment 3

[0048] On the basis of the above-mentioned embodiments, considering the stress of a single tetrahedron unit in one direction, the applied force is unidirectional compressive stress, and its stress situation is as follows Figure 5 As shown, the three edges (the bottom three edges) of the tetrahedral element perpendicular to the force direction will be mainly subjected to tensile stress and undergo tensile deformation, and the other three edges (upper three edges) will be mainly subjected to compressive stress to undergo compression deformation. Its deformation method will eventually cause the entire lattice structure to be compressed in the direction parallel to the pressure, and expand and deform in the direction perpendicular to the force.

[0049] In the vertical direction, that is, under the load parallel to the z-axis direction in the figure, the failure mode of the lattice structure is mainly the instability of the rods, and the stress of the structure is mainly concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com