Safety protection structure of high-voltage sensor

A high-pressure sensor and protective structure technology, applied in instruments, measuring fluid pressure, measuring devices, etc., can solve the problems of no safety design margin, reduced product service life, large volume, etc., to reduce weight, increase protection, and alleviate transients. The effect of high pressure shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

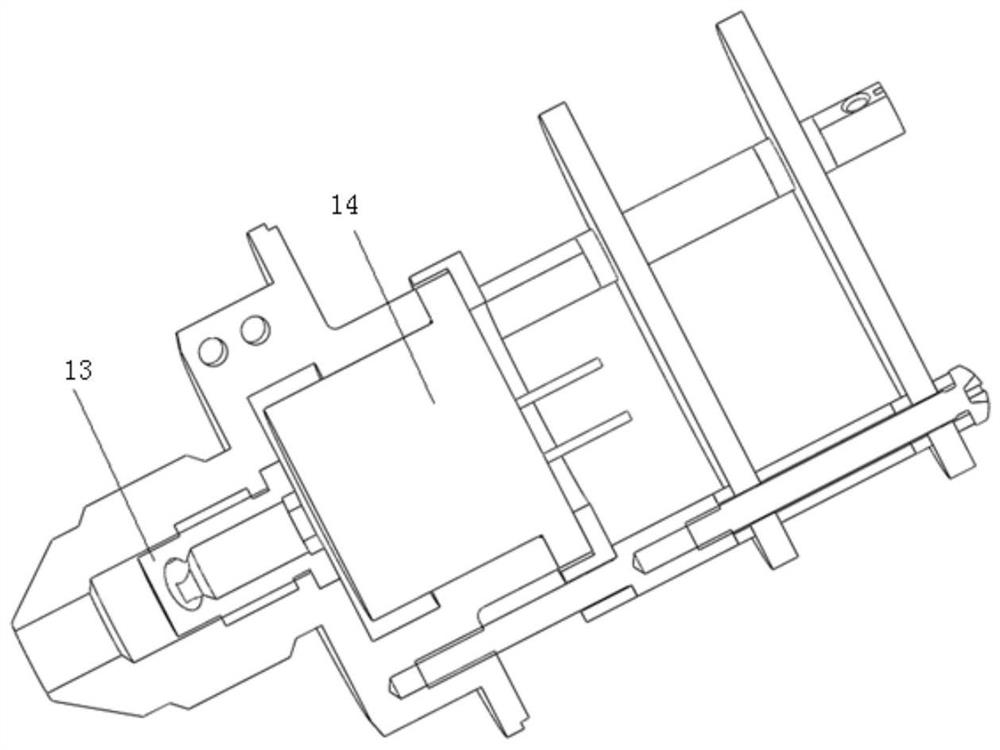

[0027] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0028] The safety protection structure design of the high pressure sensor is characterized in that:

[0029] A safety protection structure design of a high-pressure sensor is based on the existing technology, and a pressure sensor is designed for the requirements of 74-degree taper thread installation, miniaturization, sealing, and high pressure measurement. The structural design of this pressure sensor can meet the requirements of high pressure measurement, 74-degree taper thread installation, and complete machine sealing.

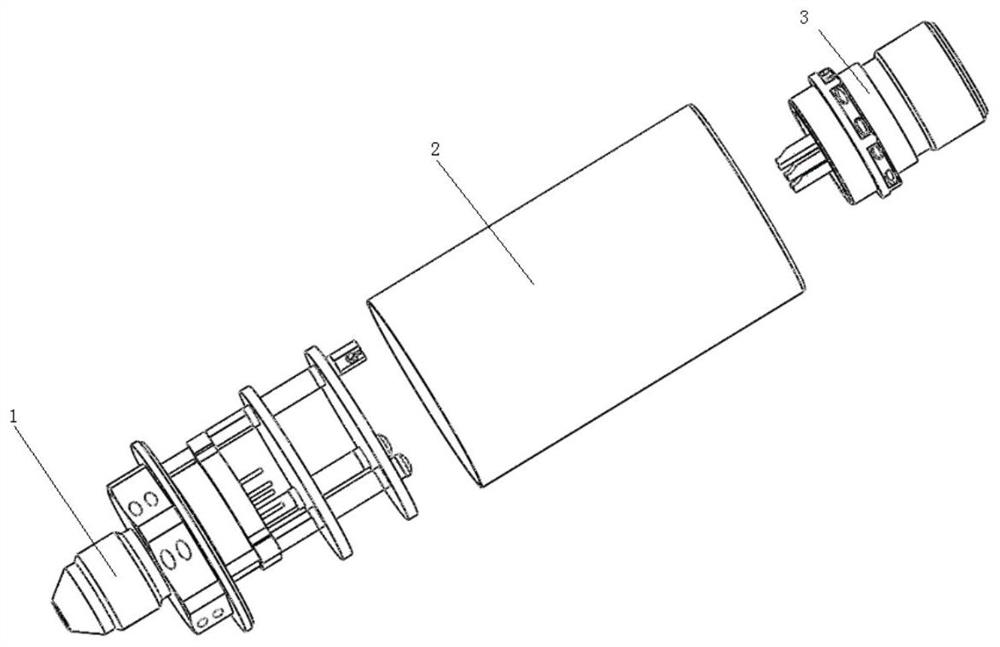

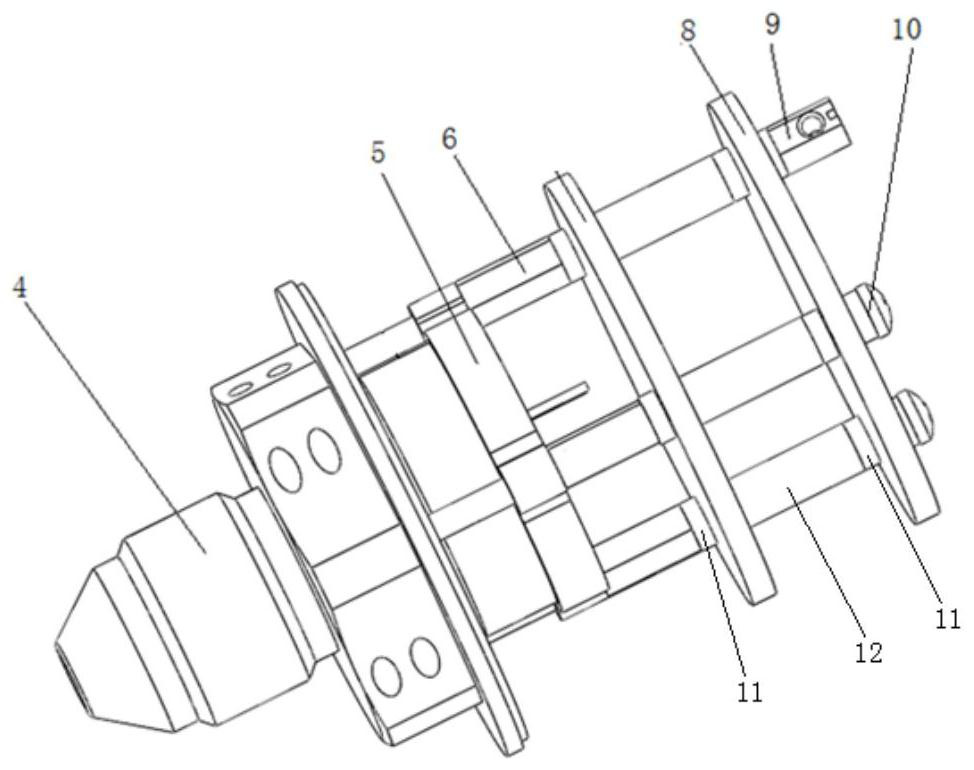

[0030] A high-voltage sensor safety protection structure includes a pressure-sensitive component 1 , a casing 2 and a socket 3 .

[0031] Such as figure 1 In the schematic diagram of the high-voltage sensor shown, the housing 2 is sequentially set on the printed circuit board component 7, the self-made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com