Environment-friendly composite board and preparation method thereof

A composite board, environmental protection technology, applied in the field of board processing, can solve the problems of violation of environmental protection concepts, environmental hazards, and difficult degradation of foam boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

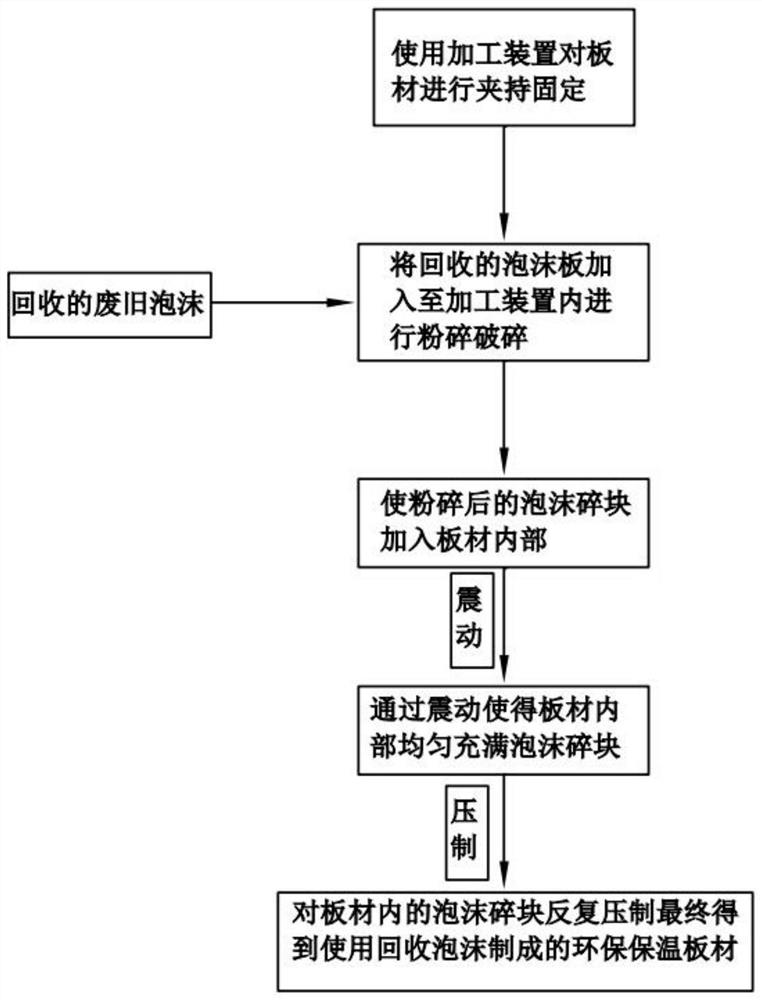

[0025] A method for preparing an environmentally friendly composite board, comprising the following steps: Step 1: Use a processing device to clamp and fix the board; Step 2: Use a processing device to crush and crush recycled foam boards; Step 3: Make the crushed foam The fragments are added to the inside of the board; Step 4: Vibrate the board through the operation of the processing device so that the inside of the board is evenly filled with foam fragments; Step 5: Operate the processing device to repeatedly suppress the foam fragments in the board and finally obtain the foam made of recycled foam Environmental protection insulation composite board.

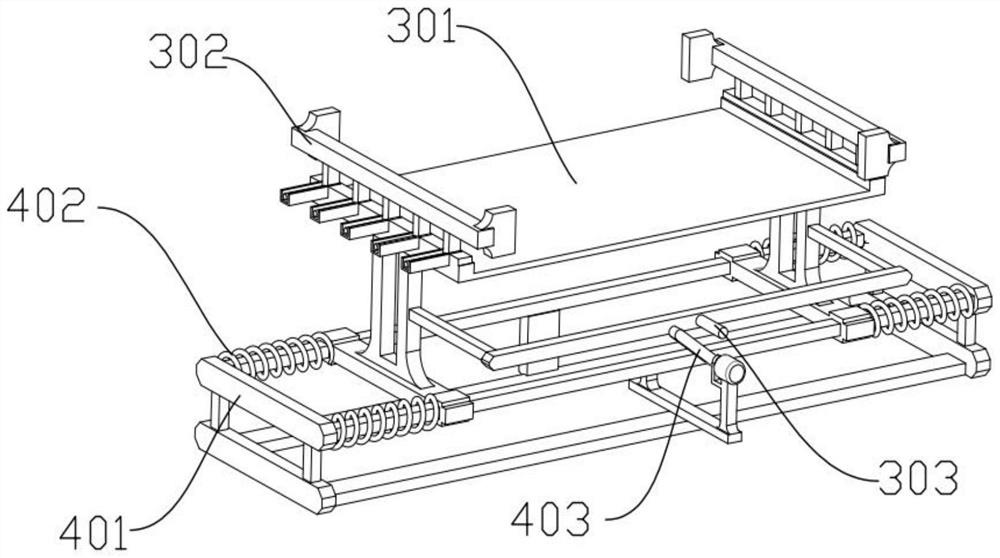

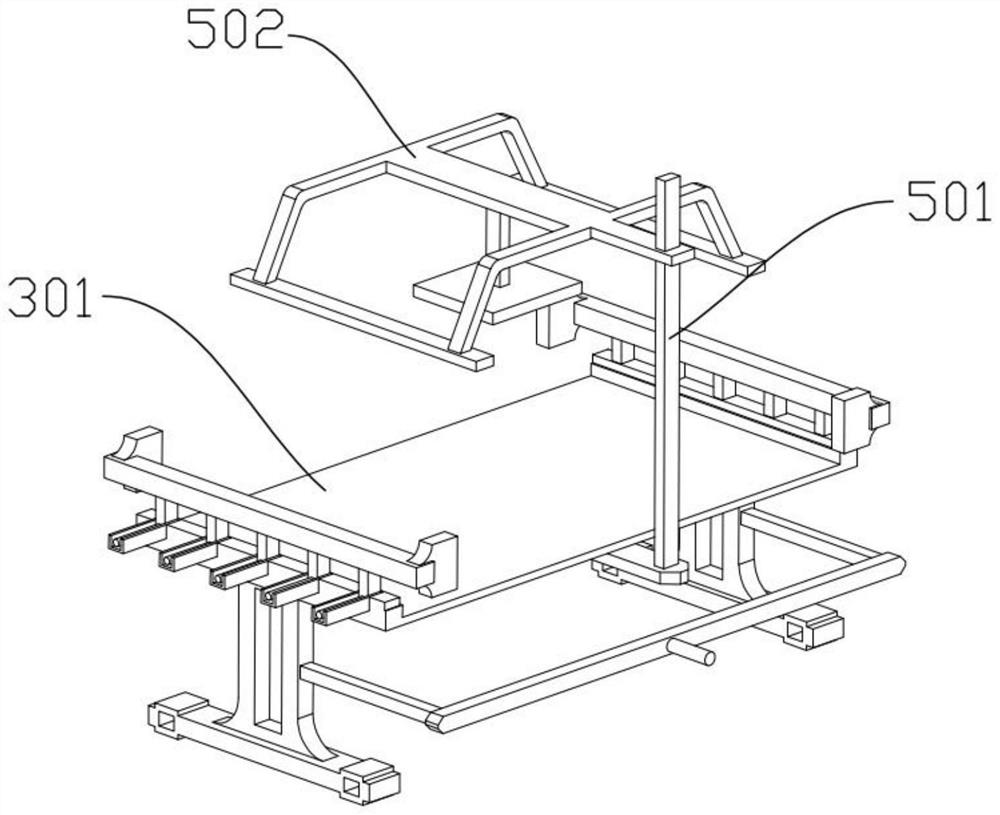

[0026] Also, as an example, such as Figure 4-5 As shown, this example solves the problem of splitting the sheet into two parts,

[0027] The plate includes opening and closing part I102, opening and closing part II103, plate body shell 101, split plate 201 and cylindrical plate 105, and the split plate 201 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com