Method for preparing foamed polylactic acid by adopting normal-temperature foaming technology

A technology of foaming polylactic acid and polylactic acid, which is applied in the field of preparation of polylactic acid materials, can solve the problems of difficult operation, large environmental pollution, incomplete treatment requirements and environmental protection, and achieves low cost, simple preparation process, Effects that are easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

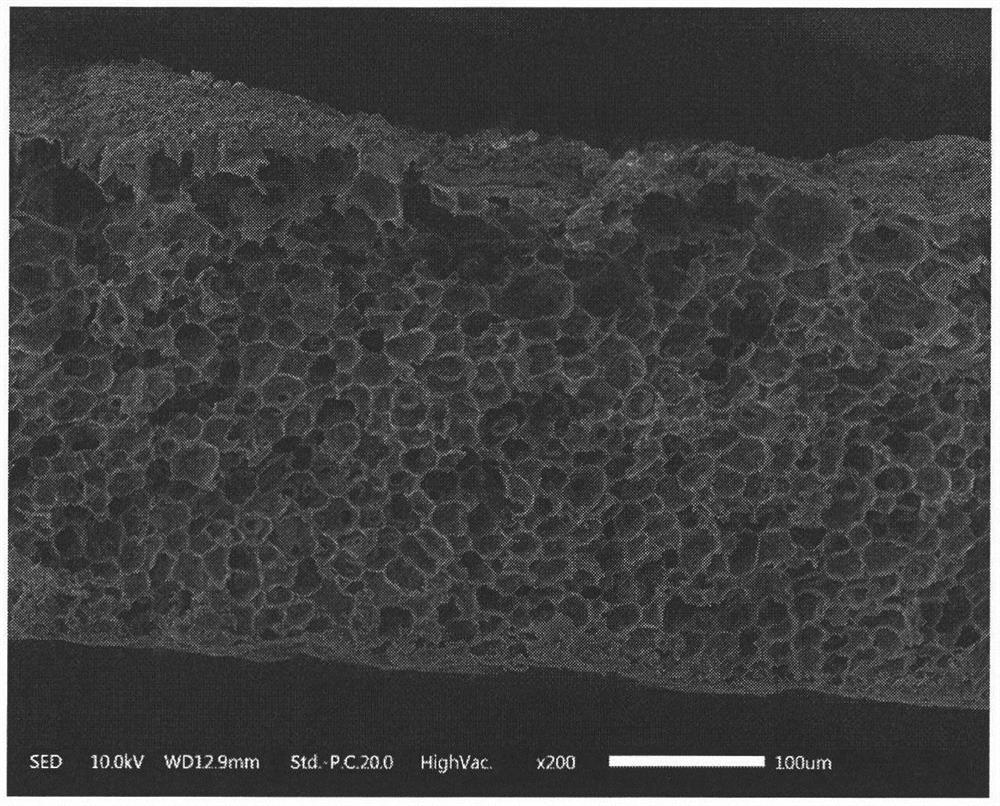

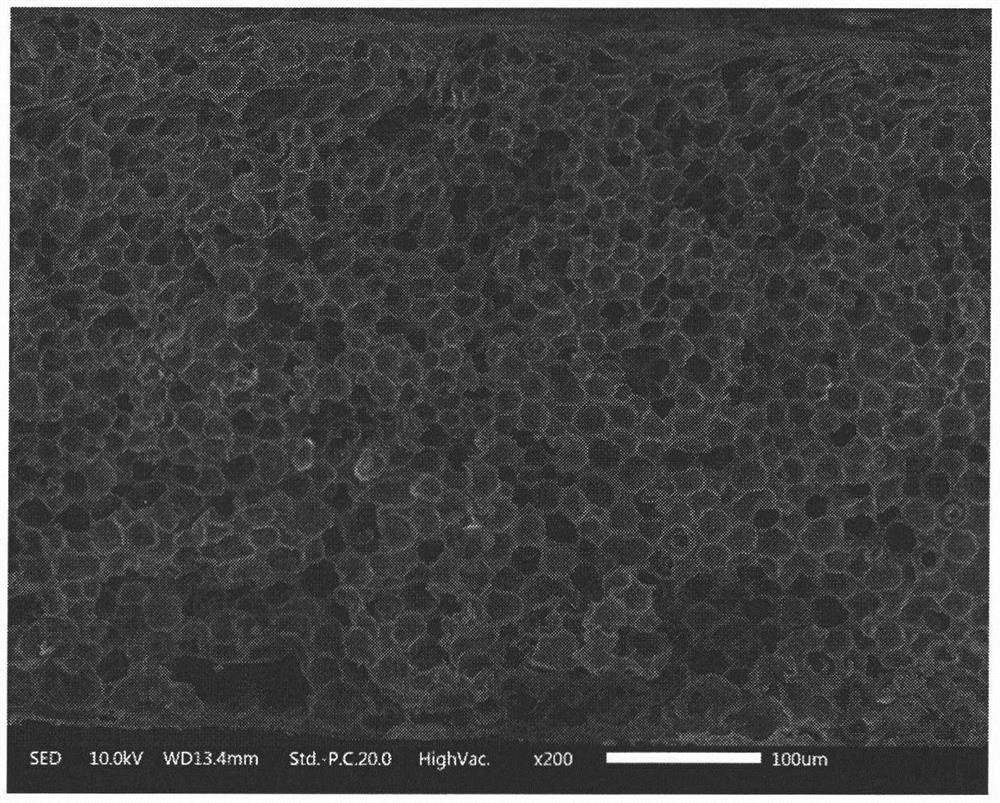

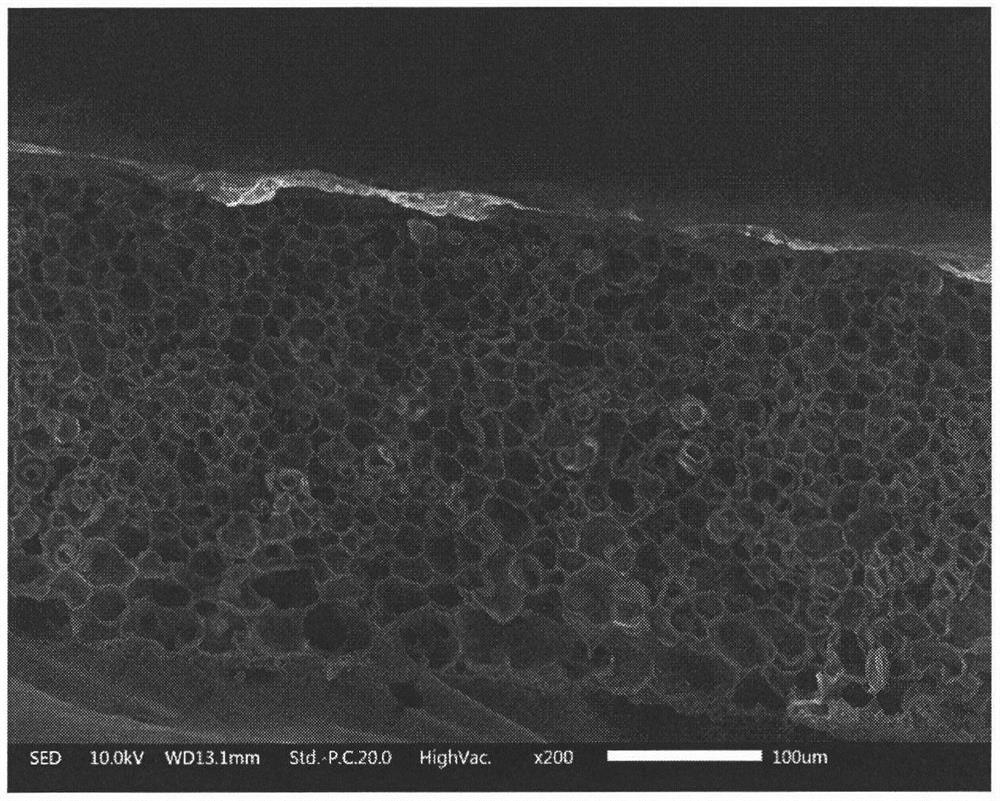

Embodiment 1

[0028] 1. Place the purchased polylactic acid in the drying box in addition to water 24h or more; 2, remove the polylactic acid particles to dissolve in the solvent at a certain ratio of 1:10; Experiment; 4, a solution used as a liquid environment is placed in an evaporating dish; 5, the dissolved polylactic acid solution is slowly poured into ethanol at room temperature; 6, wait for 2 minutes to remove the sample, dry, test; 7, no Recycling of water ethanol.

Embodiment 2

[0030] 1. Place the purchased polylactic acid in the drying box in addition to water 24 h; 2, remove the polylactic acid particles to dissolve in the solvent at a certain ratio of 1:15; Experiment; 4, a solution used as a liquid environment is placed in an evaporating dish; 5, the dissolved polylactic acid solution is slowly poured into ethanol at room temperature; 6, wait for 2 minutes to remove the sample, dry, test; 7, no Recycling of water ethanol.

Embodiment 3

[0032] 1. Place the purchased polylactic acid in the drying box in addition to water 24h or more; 2, remove the polylactic acid particles to dissolve in the solvent at a certain ratio of 1:20; Experiment; 4, a solution used as a liquid environment is placed in an evaporating dish; 5, the dissolved polylactic acid solution is slowly poured into ethanol at room temperature; 6, wait for 2 minutes to remove the sample, dry, test; 7, no Recycling of water ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com