Injection molding mold for micro motor framework

A technology of injection molding and micro motor, which is applied in the field of mold manufacturing, can solve the problems of high injection pressure, poor overall effect, small wall thickness, etc., and achieve the effect of improving product molding quality, reducing molding process difficulty, and improving overall functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

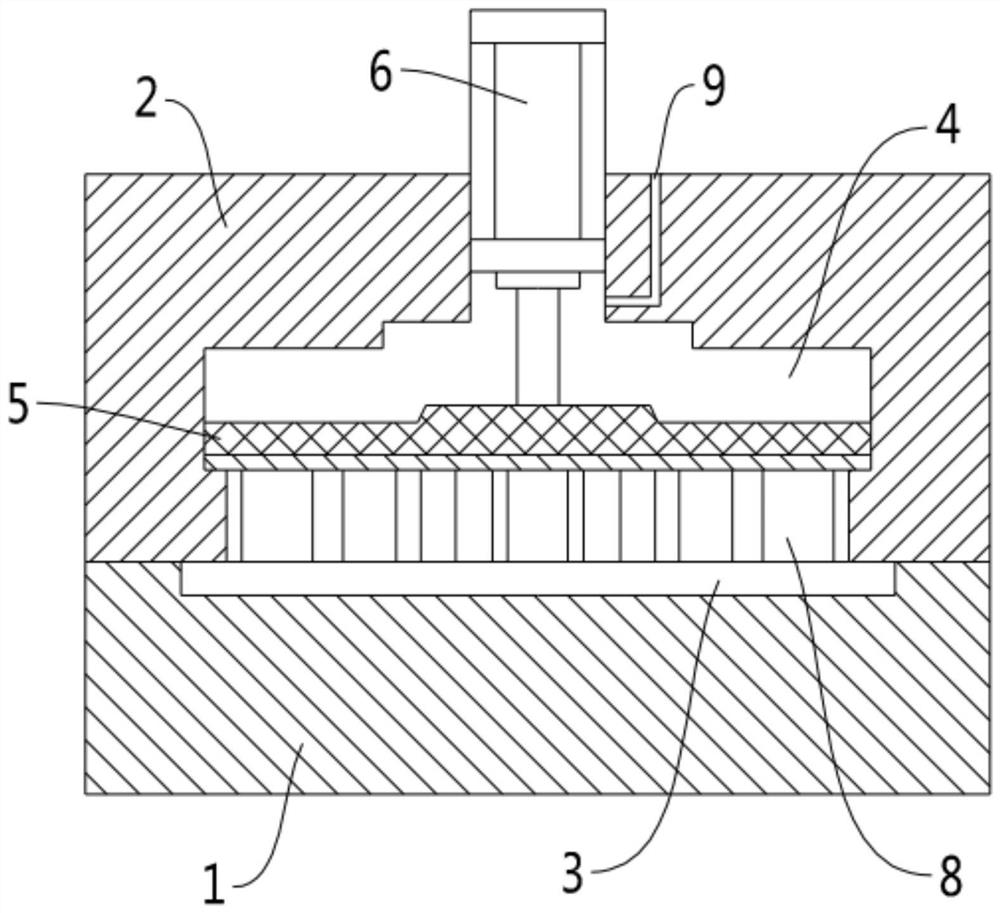

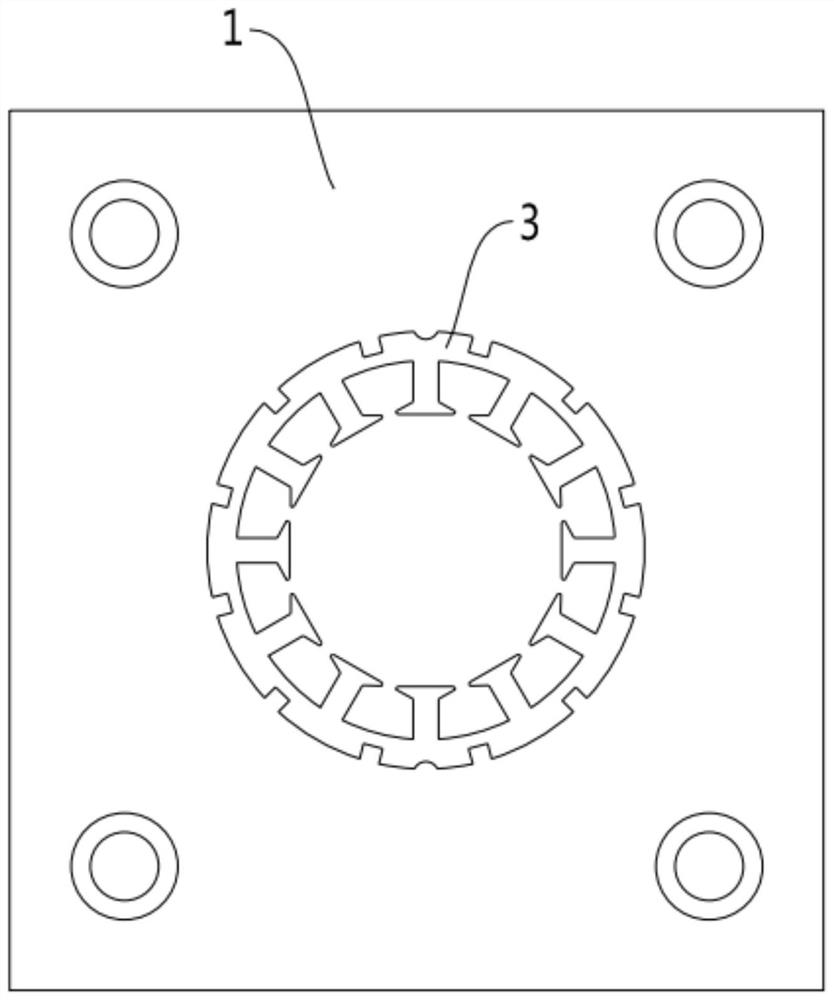

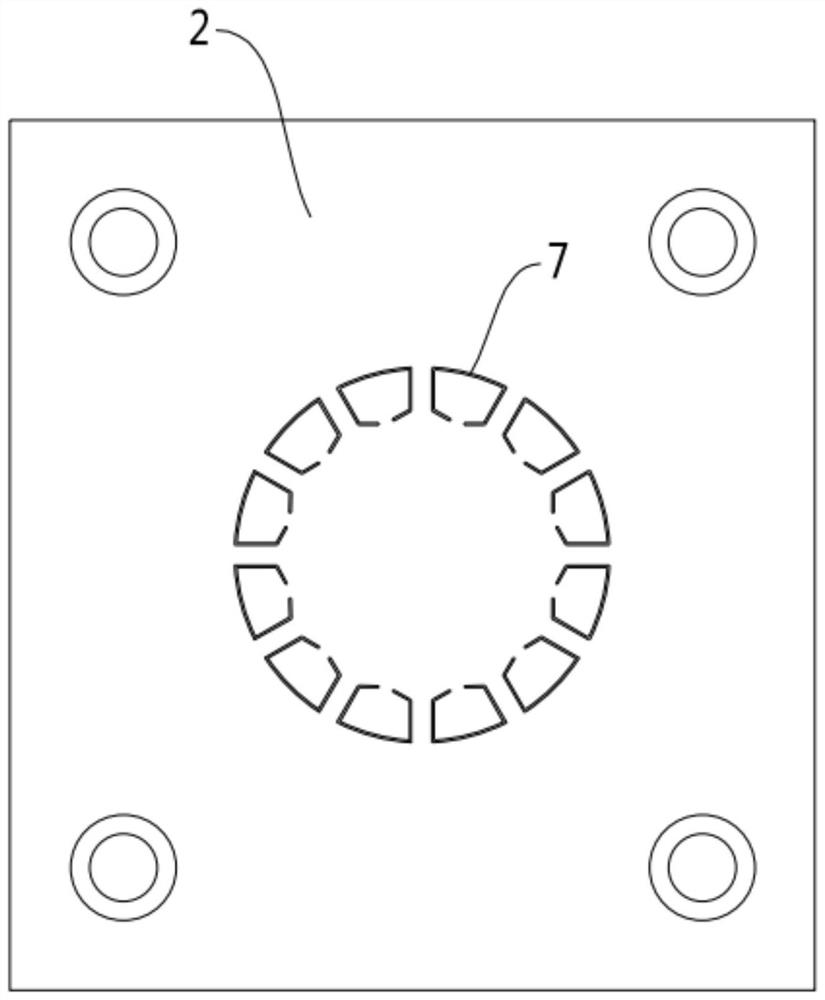

[0015] see Figures 1 to 3 As shown, a micro-motor skeleton injection molding mold involved in this embodiment includes a lower mold base 1 and an upper mold base 2 arranged above the lower mold base 1, and a notch is provided on the lower mold base 1. The forming groove 3 on the upper end surface, the inside of the upper mold base 2 is provided with a piston cavity 4, the piston cavity 4 is slidingly connected with a piston 5, and the piston 5 is provided with a linear reciprocating mechanism 6 for controlling its vertical up and down movement. The upper mold base 2 is provided with a blocking plate forming channel 7, one end of the blocking plate forming channel 7 is connected to the forming groove 3, and the other end is connected to the piston cavity 4, and one end of the blocking plate forming channel 7 is slidably connected to the piston 5 Connected, the other end of which is flush with the lower end surface of the upper die base 2, the profiled baffle forming block 8, t...

Embodiment 2

[0019] see Figures 1 to 3 As shown, the injection molding mold for a micro-motor skeleton involved in this embodiment is further set up on the basis of Embodiment 1, and a heat insulation plate is provided between the piston 5 and the profiling block forming block 8 10 , the heat insulation plate 10 is fixed on the piston 5 , and the profiling baffle forming block 8 is fixed on the heat insulation plate 10 .

[0020] In this embodiment, the setting of the heat shield 10 is used for heat insulation, avoiding the concentrated transfer of heat energy in the plastic raw material melted by high temperature to the piston 5, and preventing the excessive expansion of the piston 5 due to excessive temperature, which affects the upper and lower sides. slide.

[0021] The micro-motor skeleton injection molding mold involved in the present invention can still complete high-quality product molding operations under the condition of relatively low injection pressure, which reduces the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com