Fading ink printing equipment

An ink printing and equipment technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of inconvenient adjustment of feeding tension adjustment and slitting width, high requirements on material pH and strict temperature requirements, etc. The effect of fast speed, fast printing speed and consistent height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

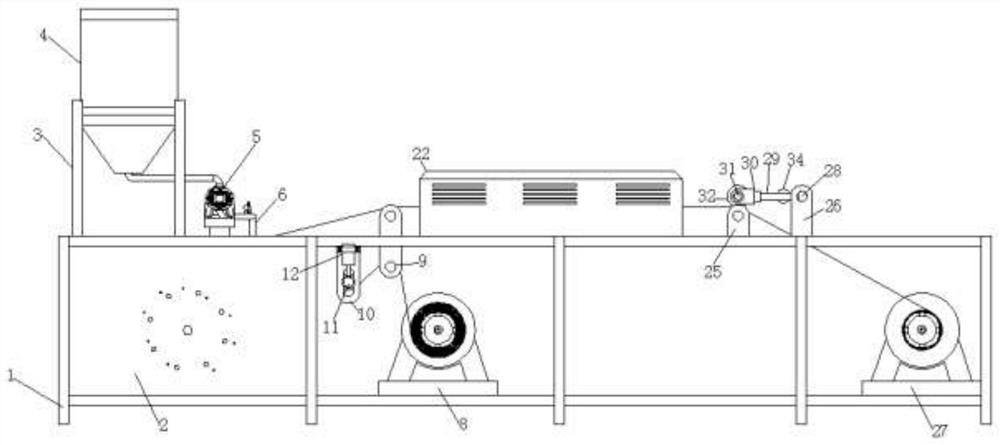

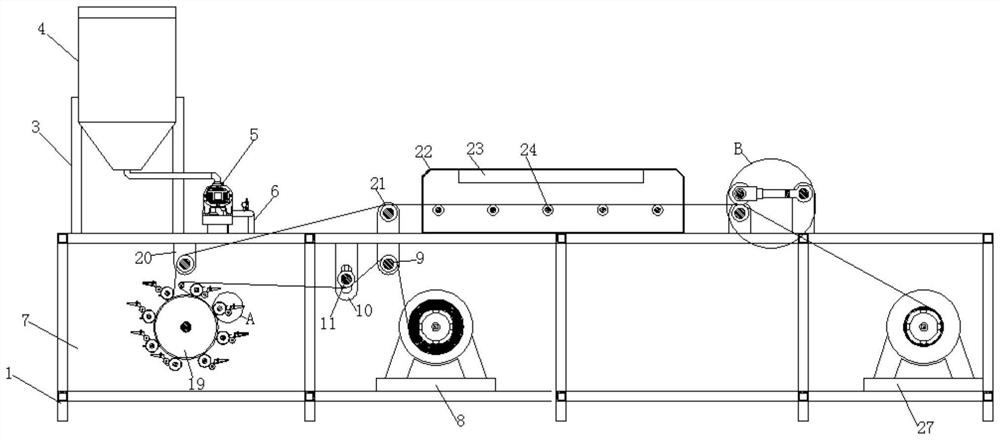

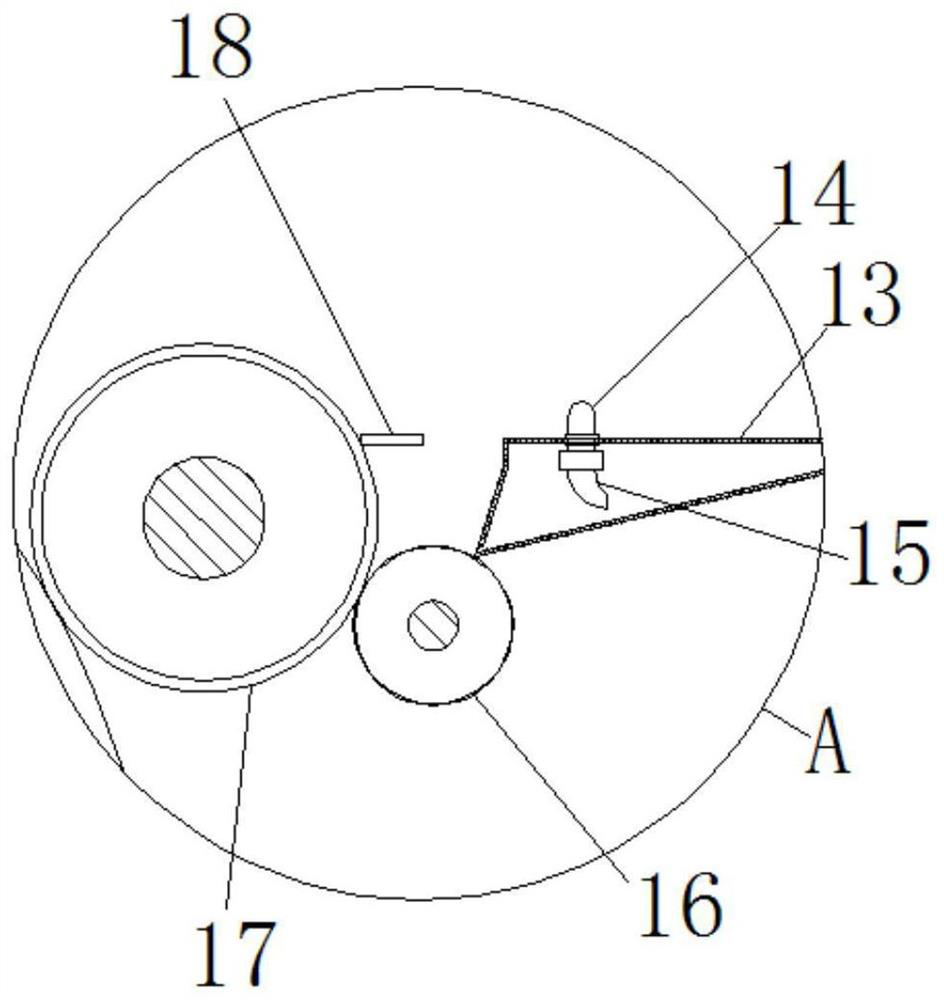

[0039] like Figure 1 to Figure 6 As shown, the embodiment of the present invention provides faded ink printing equipment, including a machine platform 1, and the machine platform 1 is composed of an upper frame, a lower frame, and five sets of support frames for supporting the upper frame and the lower frame; The front wall and the rear wall of the upper frame and the lower frame of the machine table 1, and the front baffle 2 and the rear baffle 7 between the first group of support frames and the second group of support frames; are fixedly connected to the upper wall of the machine table 1 and close to the The support 3 on the left side is fixedly connected with the ink barrel 4 at the upper end of the support 3, the upper end of the ink barrel 4 is an inlet end, and the inlet end of the ink barrel 4 is threadedly connected with a loam cake to avoid dust pollution during use.

[0040] The printing assembly for printing patterns is arranged between the front baffle 2 and the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap