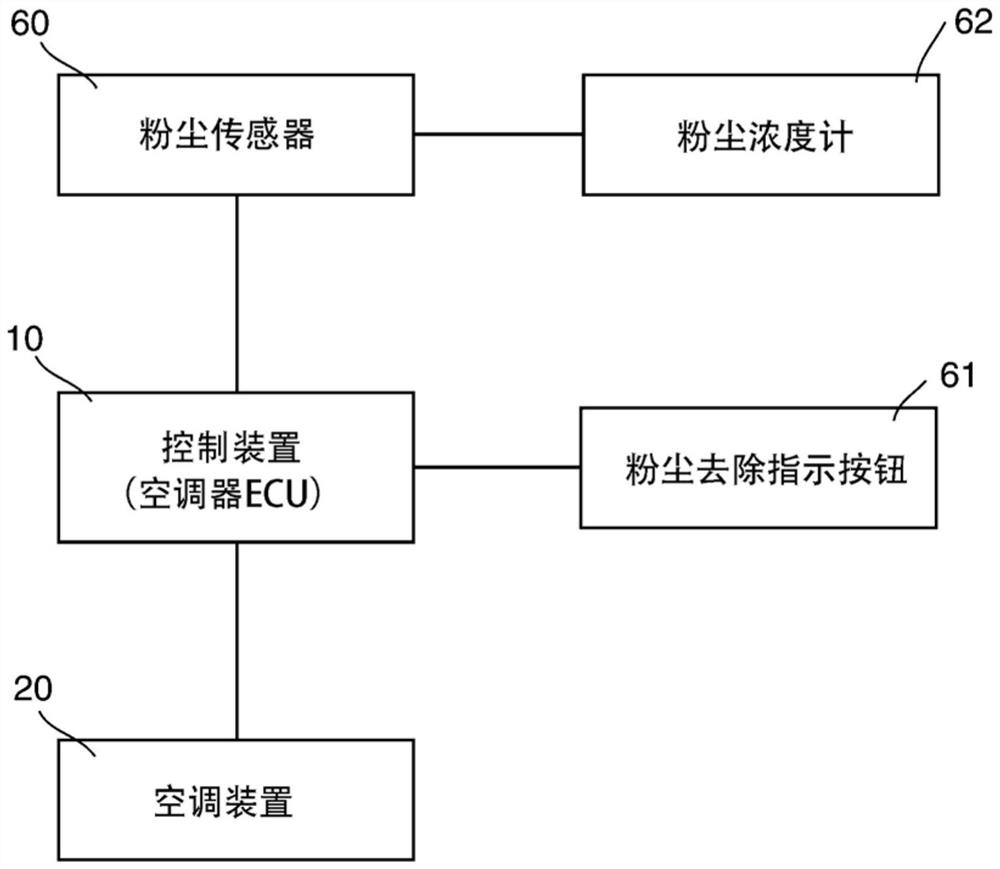

Vehicle air conditioning control device

A control device and air-conditioning device technology, which is applied to vehicle parts, transportation and packaging, air handling equipment, etc., can solve the problems of blowing temperature rise and blowing temperature drop, and achieve the purpose of suppressing the decrease of blowing temperature, suppressing the rise of blowing temperature, Comfort stays in good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

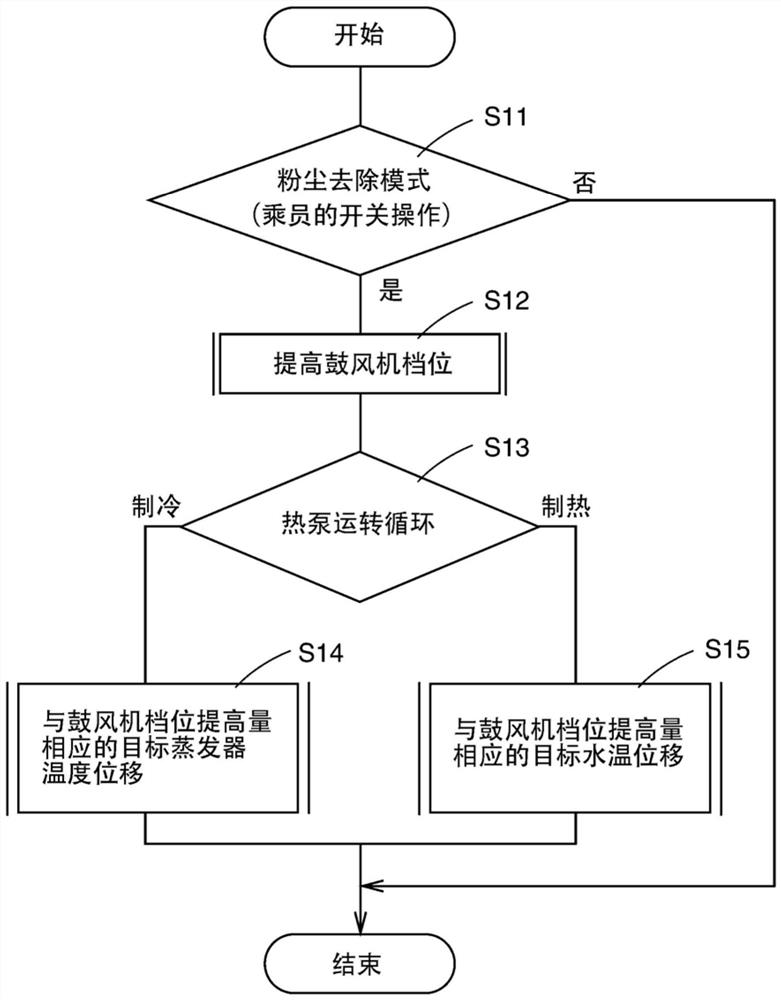

[0053] [Example 1] ( Figure 1 to Figure 5 )

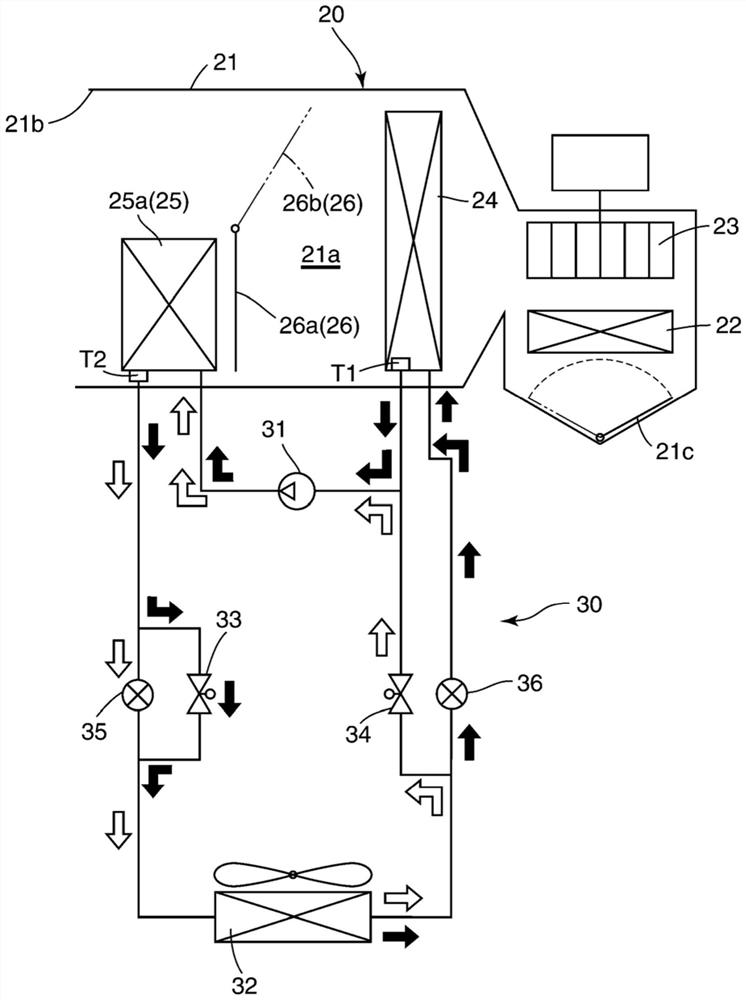

[0054] In Example 1 of the present invention, as figure 2 As shown, the evaporator 24 and the heating unit 25 of the air conditioner 20 constitute a part of a heat pump air conditioner system (heat pump air conditioner cycle) 30 . Furthermore, the heating unit 25 is constituted by an in-vehicle capacitor 25a. The heat pump air conditioner system 30 is a constituent element of the air conditioner 20 .

[0055] Although the heat pump air conditioner system 30 is not particularly limited, it is mainly mounted on a vehicle that does not have an engine (internal combustion engine), that is, an electric vehicle including an EV (Electric Vehicle) and an FCV (Fuel Cell Vehicle). (electric car) on.

[0056] The heat pump air conditioner system 30 includes, in addition to the evaporator 24 and the heating unit 25 (in-cabin capacitor 25a), a compressor 31 for compressing refrigerant (medium), a capacitor 32 outside the cabin, and first ...

Embodiment 2

[0068] [Example 2] ( Image 6 , Figure 7 )

[0069] In Example 2 of the present invention, as Image 6 As shown, the evaporator 24 and the heating part 25 of the air conditioner 20 do not constitute a part of the heat pump air conditioner system. Moreover, the heating part 25 is comprised by the heater core 25b.

[0070]The vehicle not equipped with the heat pump air conditioner system is not particularly limited, and is a vehicle equipped with an engine (internal combustion engine), that is, a gasoline vehicle or an HV (Hybrid Vehicle: hybrid vehicle) vehicle.

[0071] The evaporator 24 is a component of the refrigeration cycle 40 . The refrigeration cycle 40 is a component of the air conditioner 20 . The refrigeration cycle 40 includes a compressor 41 for compressing a refrigerant (medium), a capacitor 42 , and an expansion valve 43 in addition to the evaporator 24 .

[0072] The capacitor 42 is arranged on the downstream side of the compressor 41 in the flow directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com