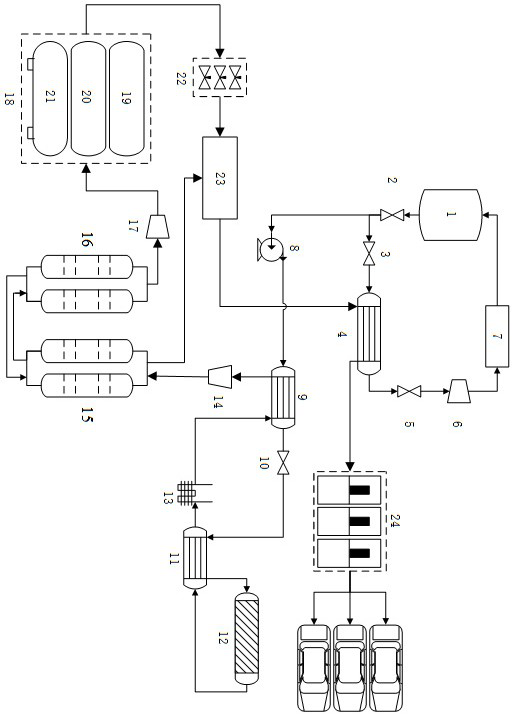

Energy-saving type on-site hydrogen production and refueling station system

A hydrogen refueling station, energy-saving technology, applied in the field of energy-saving on-site hydrogen production hydrogen refueling station system, can solve the problems of limiting hydrogen energy development of hydrogen refueling stations, limited economy of hydrogen refueling stations, high energy consumption level of hydrogen refueling stations, etc. , to achieve the effects of reducing energy consumption, improving utilization efficiency, and increasing the pressure of high-purity hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The energy-saving on-site hydrogen production and hydrogenation station system is adopted to realize in-situ hydrogen production. The temperature of the ammonia decomposition product output from the ammonia decomposition reactor is 500 °C, the temperature of the condenser is 40 °C to 50 °C, the temperature of the first evaporator is 7 °C, and the temperature of the second evaporator is 7 °C. The temperature of the device is 15°C, and the outlet pressure of the liquid ammonia pump is 3bar.

Embodiment 2

[0038] The energy-saving on-site hydrogen production and hydrogenation station system is used to realize in-situ hydrogen production. The temperature of the ammonia decomposition product output from the ammonia decomposition reactor is 530 °C, the temperature of the condenser is 30 °C ~ 40 °C, the temperature of the first evaporator is 2 °C, and the temperature of the second evaporation is 2 °C. The temperature of the device is 10℃, and the outlet pressure of the liquid ammonia pump is 7bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com