Safety auxiliary equipment for steam turbine

An auxiliary equipment and steam turbine technology, applied in the field of steam turbines, can solve the problems of poor damping effect of the base and loose parts of the steam turbine, so as to enhance the shock absorption effect, avoid loose parts and damage, and improve the effect of buffering and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

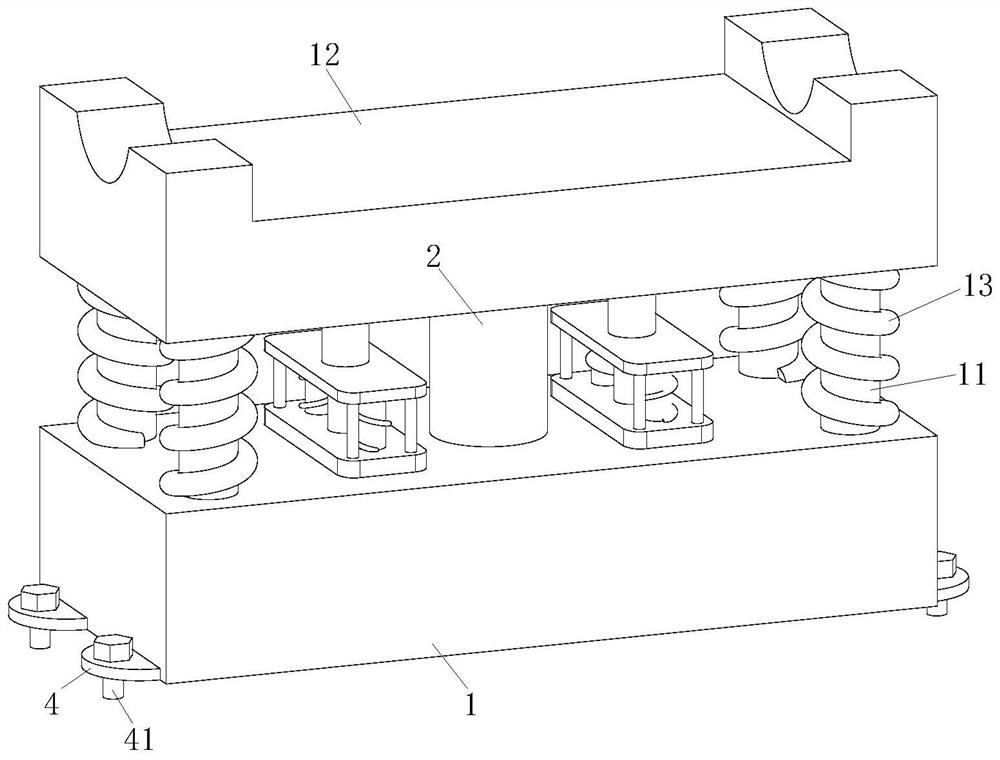

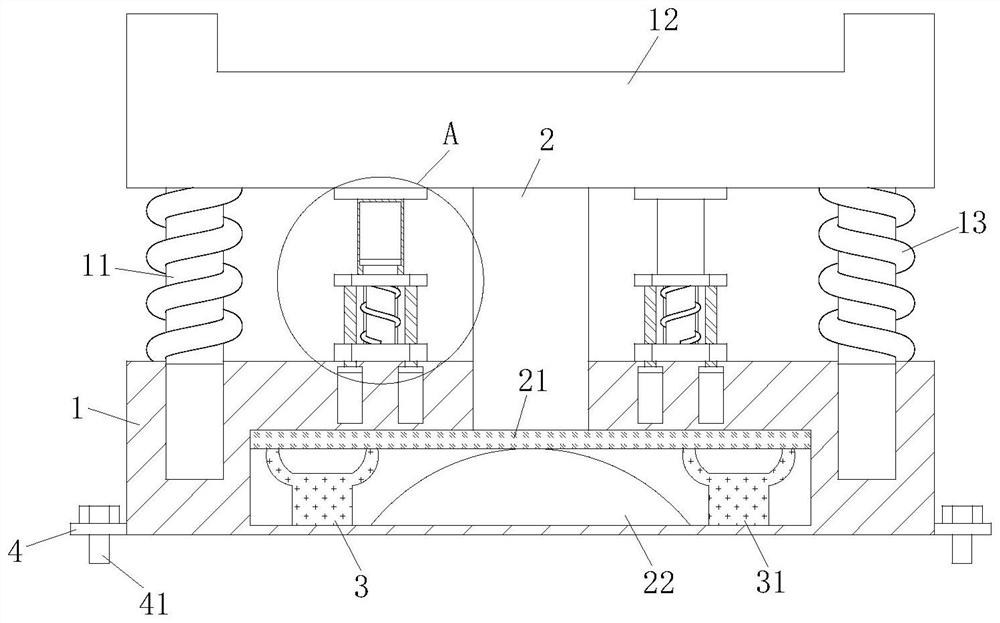

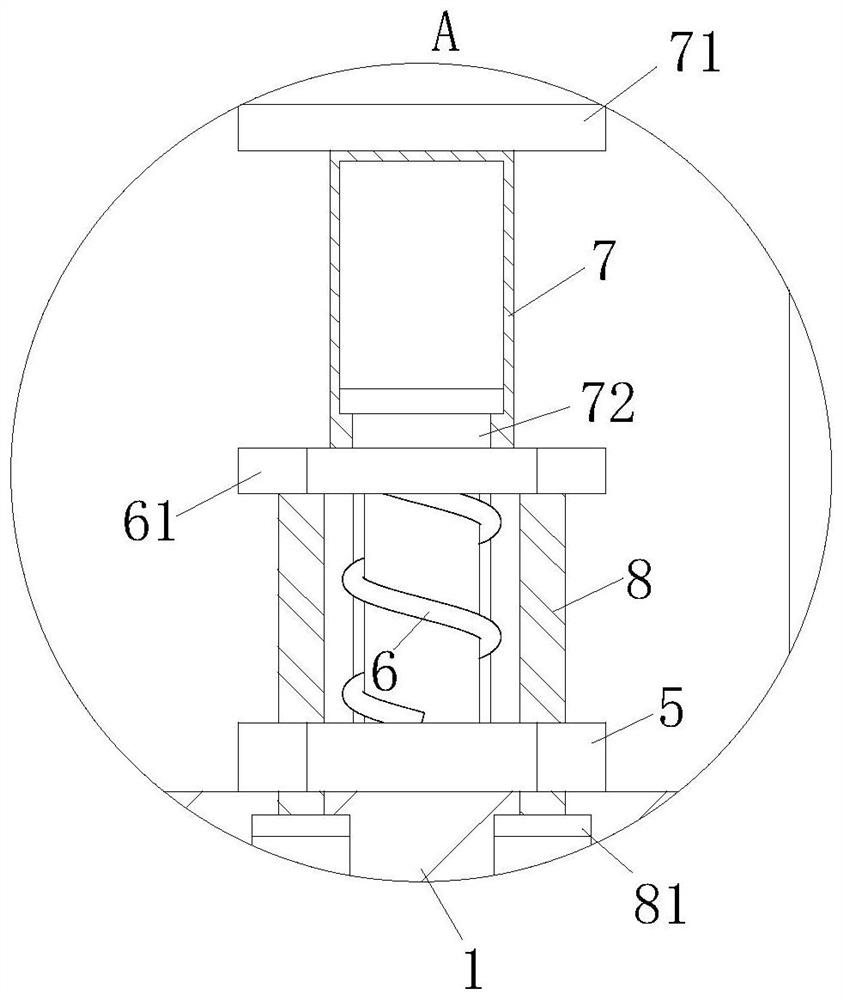

[0026] see Figure 1-4 As shown, a steam turbine safety auxiliary equipment includes a supporting square base 1 and a shock absorbing unit; the shock absorbing unit is arranged on the side wall of the supporting square base 1; the shock absorbing unit includes a supporting slide bar 11 and a concave placement plate 12 1. No. 1 elastic member 13 and buffer mechanism; the support slide bar 11 is slidably connected to the inner side wall of the support square base 1; the concave surface placement plate 12 is fixedly connected to the end of the support slide bar 11; the No. 1 elastic member 13 is socketed on the side wall of the supporting slide bar 11; the buffer mechanism is arranged at the bottom of the concave placing plate 12; during work, the staff installs the steam turbine on the end of the concave placing plate 12, when the steam turbine shakes during operation, The concave placing plate 12 will be pressed downwards, the concave placing plate 12 will press the four sets o...

Embodiment 2

[0035] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, the end of the connecting plate 5 is fixedly connected with an elastic protective pad 9; the shape of the elastic protective pad 9 is circular; when working, The steam turbine vibrates in operation, driving the concave surface placing plate 12 to press the pressing plate 61, the pressing plate 61 slides downward, and is pressed on the elastic protective pad 9 fixedly connected to the end of the connecting plate 5, and the elastic protective pad 9 fixedly connected to the end of the connecting plate 5 The pad 9 plays the role of cushioning and shock absorption, and avoids wear and tear caused by pressing and collision between the pressing plate 61 and the connecting plate 5 .

[0036] Working principle, when working, the staff installs the steam turbine on the end of the concave placing plate 12, when the steam turbine shakes during operation, the concave placing plate 12 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com