Gasifier system and semi-coke distribution control method

A gasification furnace and semi-coke technology, applied in the field of coal gasification, can solve the problems of uncoordinated distribution ratio of semi-coke, unstable entrainment of synthetic gas, and unstable operation of the lock bucket system, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

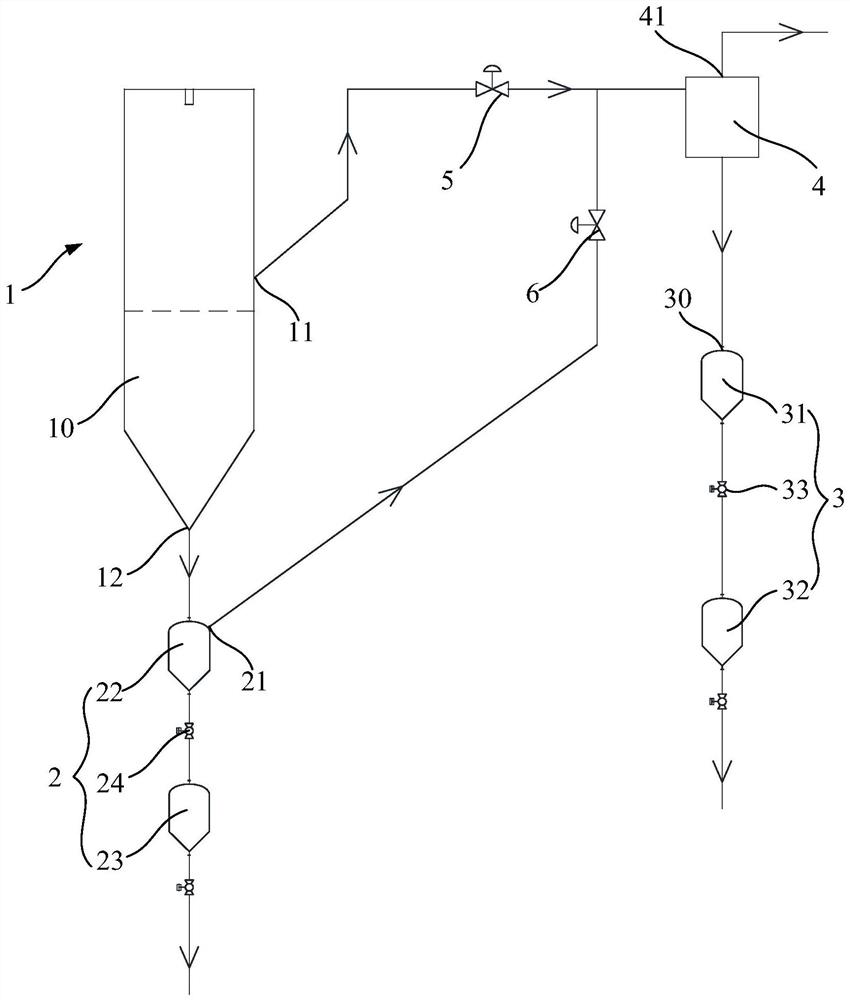

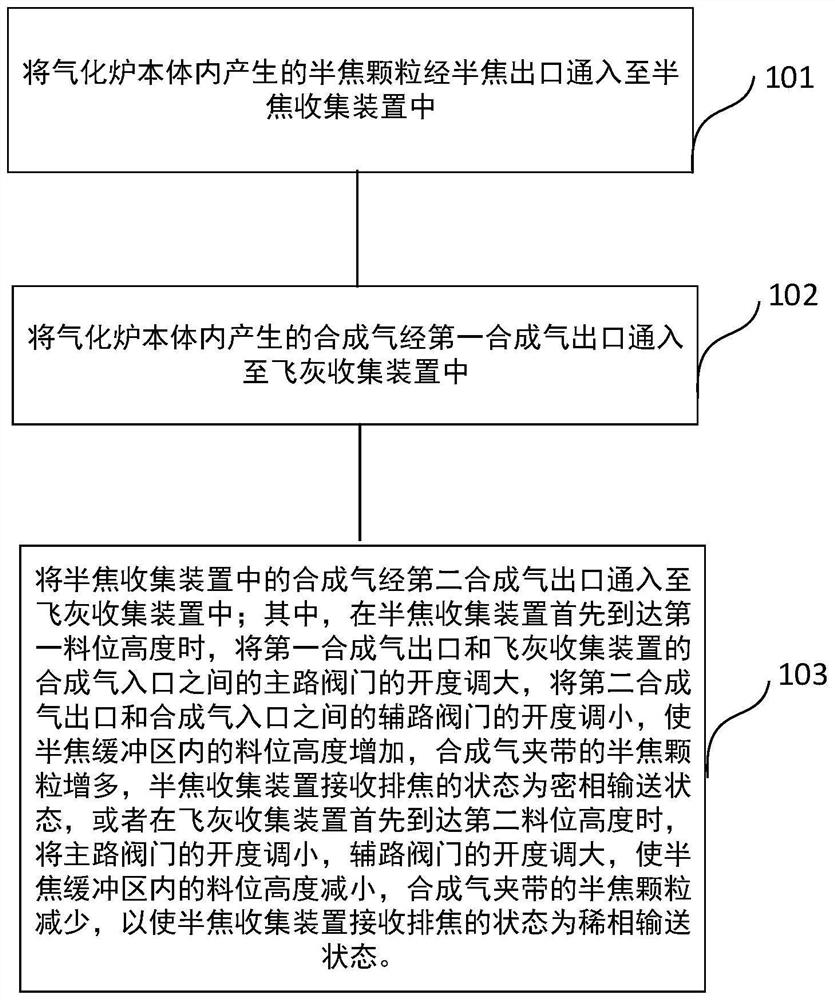

[0038] like figure 1 and 2 As shown, this embodiment provides a gasifier system, which includes a gasifier body 1, a semi-coke collecting device 2 and a fly ash collecting device 3, wherein,

[0039]The gasifier body 1 has a semi-coke outlet 12 and a first synthesis gas outlet 11, the semi-coke collecting device 2 is used to collect the semi-coke particles produced by the reaction in the gasifier body 1, and the semi-coke outlet 12 of the gasifier body 1 is communicated with To the semi-coke collecting device 2, the semi-coke collecting device 2 also has a second syngas outlet 21; the fly ash collecting device 3 is used to collect semi-coke particles entrained in the syngas produced by the reaction in the gasifier body 1, and the fly ash is collected The device 3 has a synthesis gas inlet, and both the first synthesis gas outlet 11 and the second synthesis gas outlet 21 are connected to the synthesis gas inlet 30 of the fly ash collection device 3, so that the synthesis gas i...

Embodiment 2

[0059] like Figure 3-5 As shown, the basic settings of the gasifier system in this embodiment are the same as those in Embodiment 1, and the only difference is:

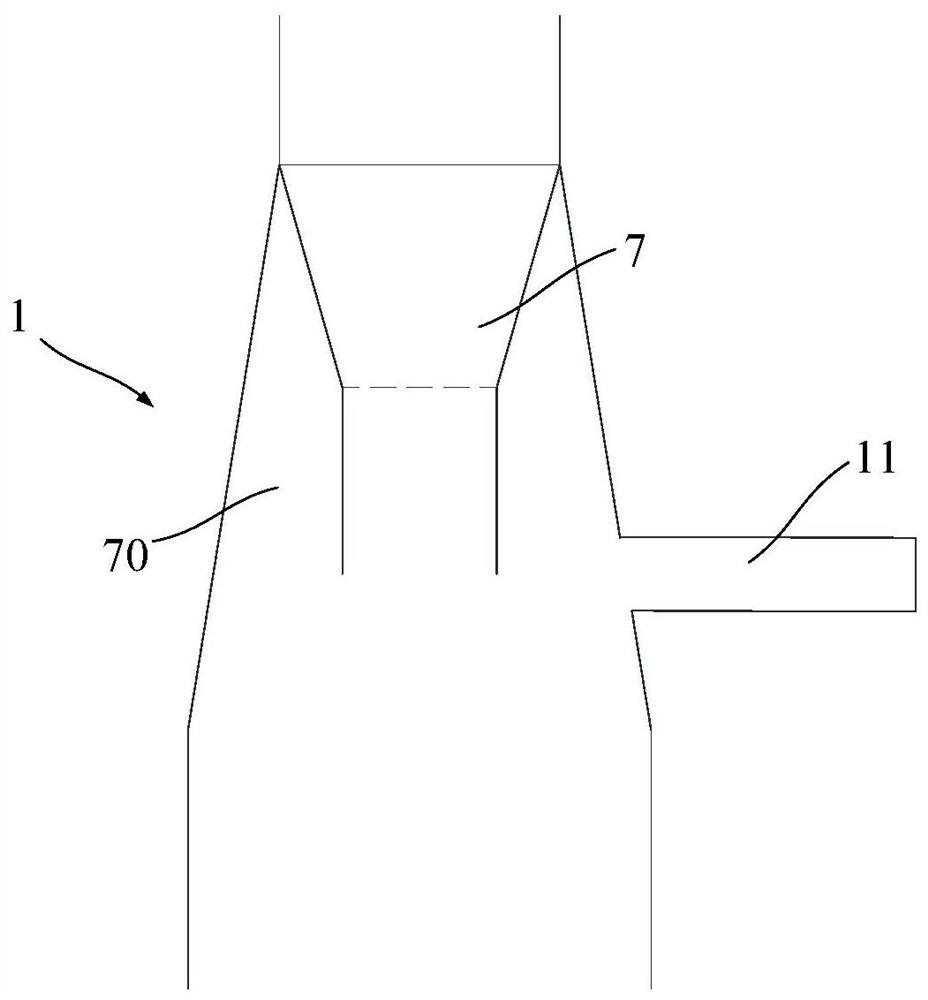

[0060] like image 3 As shown, the gasifier body 1 is also provided with an inner guide tube 7, the bottom area of the gasifier body 1 forms a semi-coke buffer zone 10, the inner guide tube 7 is located above the semi-coke buffer zone 10, and the inner guide tube 7 An annular space 70 is formed between the outer wall of the flow cylinder 7 and the inner wall of the gasifier body 1 , and the first synthesis gas outlet 11 is communicated with the annular space 70 . The arrangement of the inner guide tube 7 can increase the flow rate of the synthesis gas at the central position of the gasification body, which is beneficial to the preliminary inertial separation of the semi-coke and the synthesis gas.

[0061] Since the efficiency of inertial separation is not stable enough to ensure that the amount of semi-coke ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com