Weft-knitted double-sided fabric with deodorization function and production method of weft-knitted double-sided fabric

A deodorant function, double-sided fabric technology, applied in weft knitting, dyeing, fabric surface trimming, etc., can solve the problems of poor fabric appearance, poor skin penetration, poor moisture absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

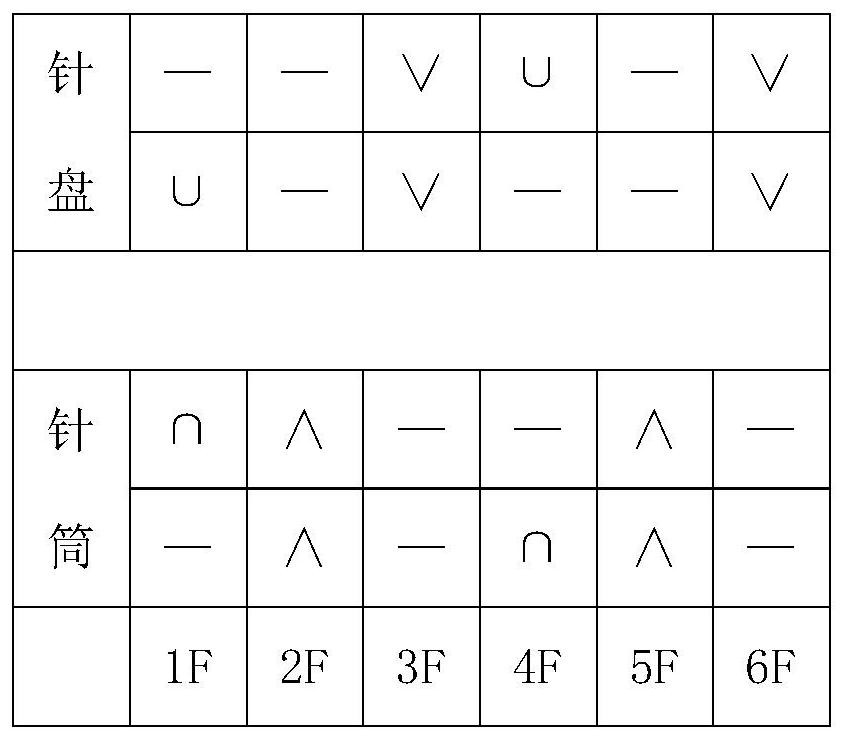

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] refer to figure 1 . A weft-knitted double-sided fabric with anti-odor function, including a fabric body, the fabric body includes a surface layer yarn, a liner yarn, a connecting layer and a bottom layer yarn, and the surface layer yarn is 20D / 24F high-elastic semi-glossy nylon DTY yarn as the fabric The top layer yarn, the backing yarn and the connecting layer are all 20D deodorant Lycra spandex, the bottom yarn is 100S / 1 Micro Modal yarn, the top layer yarn and the backing yarn are combined to form the outer layer, and the bottom yarn and the backing yarn are combined to form the inner layer layer, the outer layer and the inner layer are connected by a connecting layer. By choosing 20D / 24F high-elastic semi-gloss nylon DTY yarn as the surface layer yarn of the fabric, the filament yarn is used as the front of the fabric, which is not easy to produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com