Hollow glass convenient for replacing drying agent and accessories thereof

A desiccant and hollow technology, which is applied to building components, windows/doors, buildings, etc., can solve the problems of time-consuming and laborious, impossible to replace the desiccant, and poor drying effect, so as to reduce maintenance difficulty, maintain continuous drying effect, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

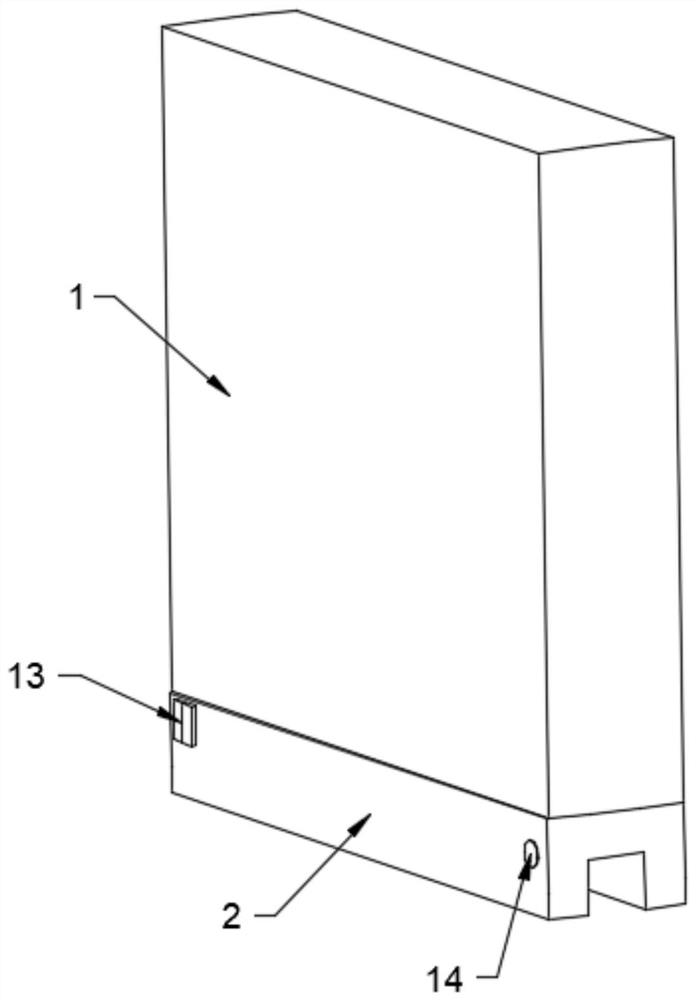

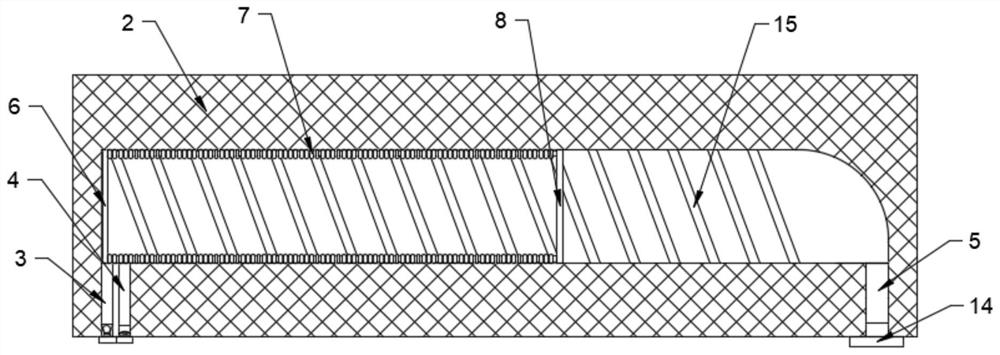

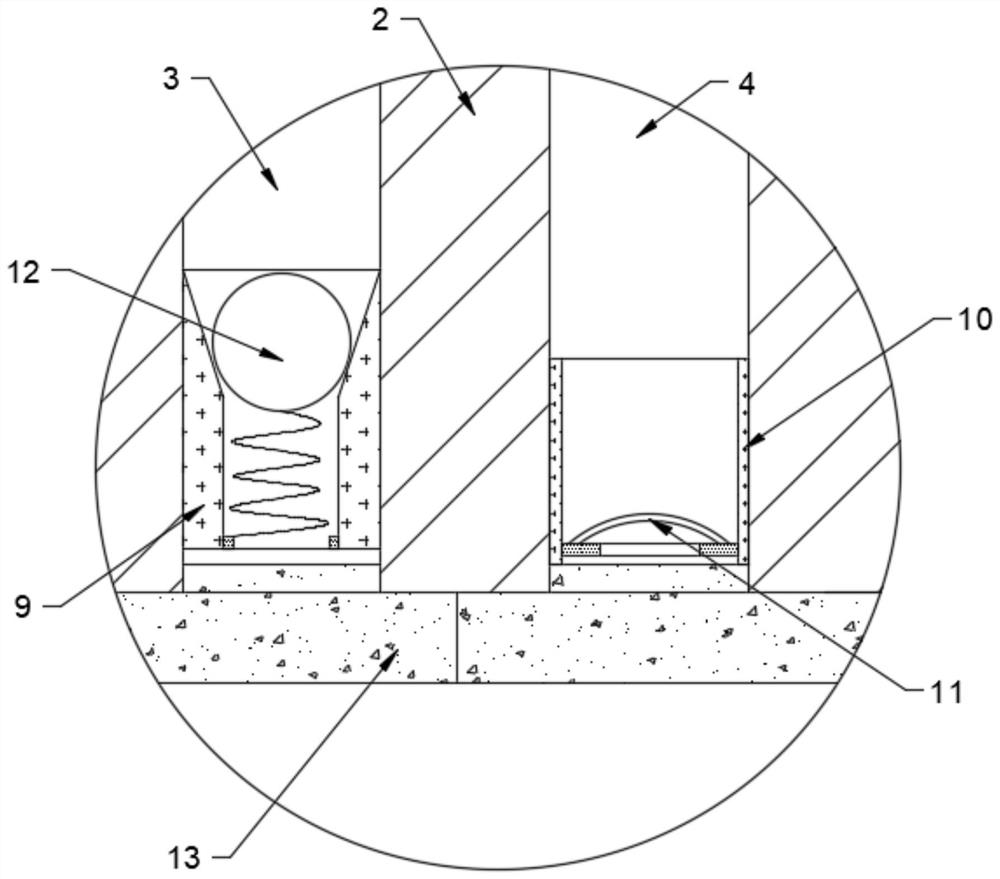

[0042] see Figure 1-3 with Figure 8 , a hollow glass and its accessories for easy replacement of desiccant, including a hollow glass body 1, the lower end of the hollow glass body 1 is fixedly connected with a drying box 2 connected to it, and the left end of the drying box 2 is sequentially provided with air intakes from back to front Holes 3, feed holes 4 and discharge holes 5, the rear inner wall of the drying box 2 is fixedly connected with an air equalizing pipe 6 connected with the air inlet 3, and the front end of the equalizing air pipe 6 is fixedly connected with a pair of pneumatic deformation tubes 7, two pneumatic The extruding plate 8 is fixedly connected between the deformation tubes 7, the special-shaped air intake cylinder 9 is fixedly connected in the air inlet 3, the feeding shield 10 is fixedly connected in the feeding hole 4, and a sealing inlet is arranged in the feeding shield 10. The material assembly 11, the upper and lower inner walls of the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com