Novel temperature thermocouple for turboset

A temperature measuring thermocouple and steam turbine unit technology, applied in the direction of measuring heat, using electrical devices, using electromagnetic means, etc., can solve the problems of easy clamping of clamps, disconnection of measuring circuits, and dead spots of cylinder temperature display, and reduce the Labor loss, improved stability and sealing, improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

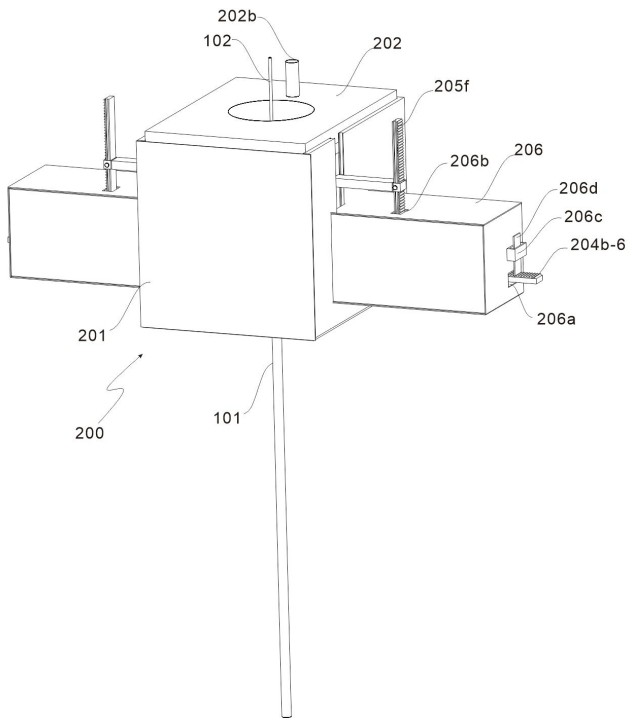

[0029] refer to Figures 1~5 , which is the first embodiment of the present invention. This embodiment provides a new type of temperature measuring thermocouple for steam turbine units. The new type temperature measuring thermocouple for steam turbine units includes a temperature measuring mechanism 100 and a fixing mechanism 200. The expansion of the fixing mechanism 200 The mutual cooperation of the assembly 204 and the extrusion assembly 205 plays a role of fixing and sealing the temperature measuring mechanism 100 .

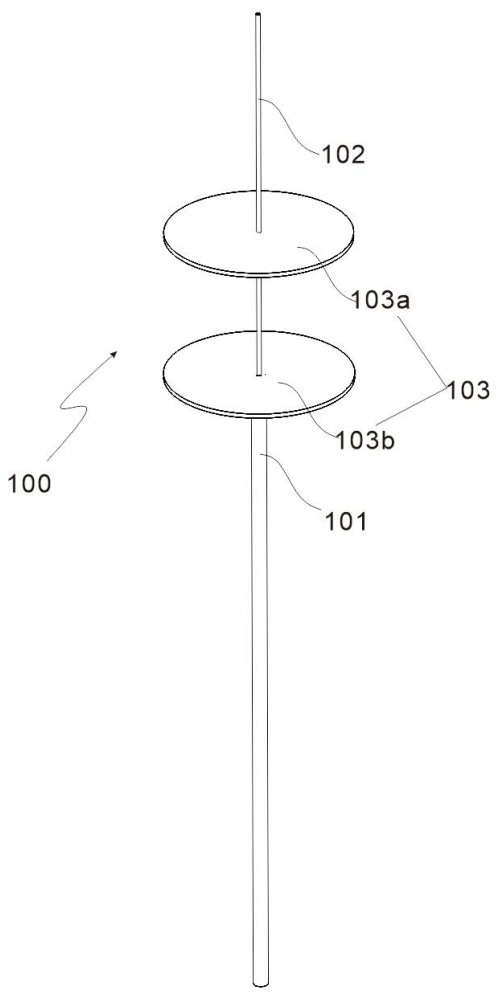

[0030] Specifically, the temperature measurement mechanism 100 includes a protective tube 101, an armored thermocouple wire 102 with one end disposed in the protective tube 101, and a sealing member 103 disposed on the armored thermocouple wire 102; the armored thermocouple wire 102 is provided with Inside the protection tube 101 , the protection tube 101 protects the armored thermocouple wire 102 , and one end of the armored thermocouple wire 102 extends out...

Embodiment 2

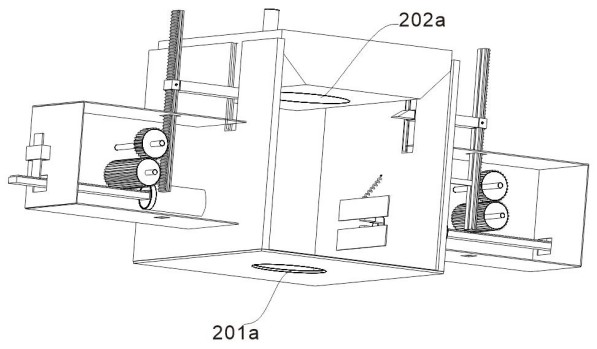

[0036] refer to Figures 1~7 , is the second embodiment of the present invention, which is based on the previous embodiment.

[0037] Specifically, the expansion assembly 204 includes a sliding rod 204a slidably disposed in the hollow tube 203, one end of the sliding rod 204a is symmetrically provided with two sets of upper and lower rotating seats 204a-1, and the rotating seats 204a-1 are rotatably connected with a support 204b through a rotating shaft ; The support 204b can rotate around the rotating seat 204a-1.

[0038] Preferably, the support member 204b includes a first support rod 204b-1 that is rotatably connected to the rotating base 204a-1, an inner cavity is opened at one end of the first support rod 204b-1, and a sliding insert is inserted into the inner cavity of the first support rod 204b-1. A second support rod 204b-2 is connected, a first spring 204b-3 is fixedly connected between the inner cavity bottom wall of the first support rod 204b-1 and one end of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap