Bulk material chip mounting tray based on full-automatic chip mounter

A placement machine, fully automatic technology, applied in the direction of electrical connection formation of printed components, electrical components, printed circuit manufacturing, etc., can solve the problems of occupying the placement material level, solder can not be welded in time, increase the cost of circuit analysis, etc., to improve The effect of placement accuracy, improvement of placement work efficiency, and meeting the needs of small batch production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more clear, a kind of automatic placement machine based bulk material placement tray of the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention. invention.

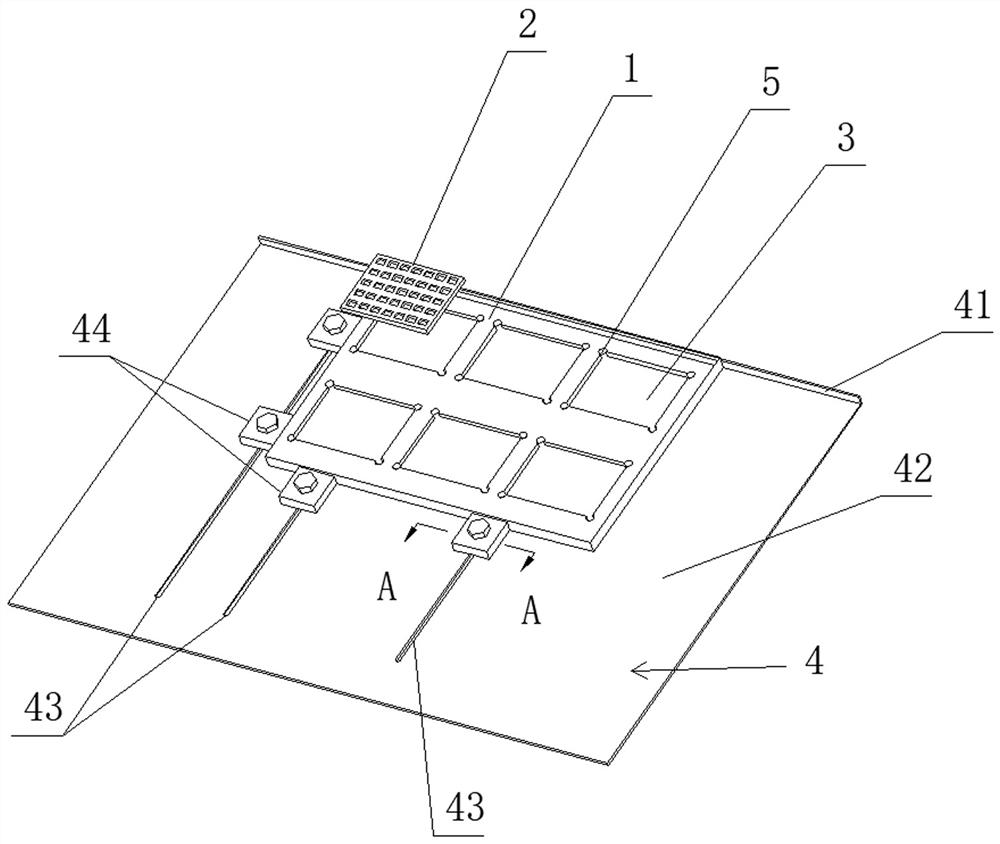

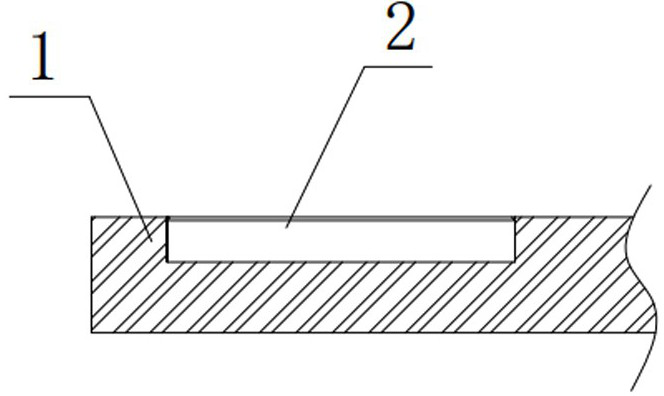

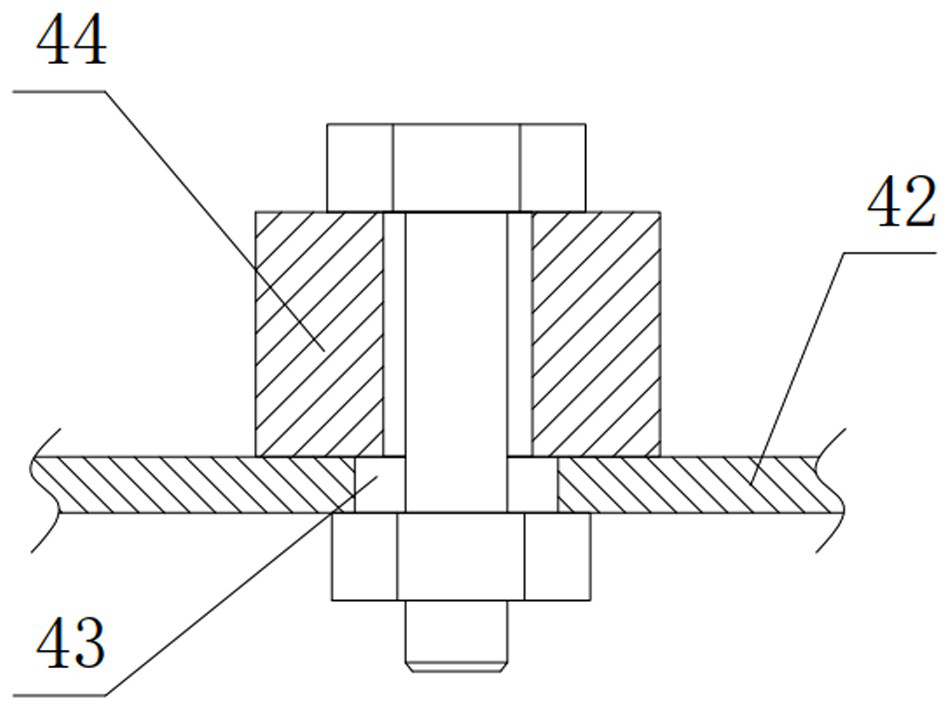

[0019] Such as figure 1 , figure 2 As shown, a bulk placement tray based on a fully automatic placement machine is used in conjunction with the KE-6060L placement machine. It includes a pallet 1 and a set of packaging boxes 2 (only one is shown in the figure). The supporting plate 1 is a rectangular plate made of Bakelite, and its upper and lower surfaces are parallel to each other. The packaging box 2 is the packaging box that comes with the bulk purchase, and does not need to be made separately. Here, the packaging box 2 is a rectangular box, which is a common shape on the market. The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com