Food material composition and membrane bioreactor design comprising filamentous fungal particles

A filamentous fungus, food technology, applied in the field of food material composition and membrane bioreactor design containing filamentous fungal particles, can solve the problem of inaccessible or limited access to aseptic facilities or/or need to be sealed aseptic systems And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 26

[0264] Example 26 illustrates the stability of the liquid dispersion (i.e.mm of the present invention). The milk was allowed to stand for 15 days and 30 days in the frost, and the visible separation was observed in any sample. Milk has not shown a decrease in flavor or odor.

[0265] In some embodiments, the dispersion comprises at least about 4%, at least about 5%, at least about 6%, at least about 7%, at least about 8%, at least about 9%, at least about 10%, at least about 11%, at least About 12%, at least about 13%, at least about 14%, at least about 15%, at least about 16%, at least about 17%, at least about 18%, at least about 19%, at least about 20% solid. In other embodiments, the liquid dispersion of the present invention will have a solid content of from about 4% to about 30% or between 4% to 30%.

[0266] Liquid dispersion can be used as a drink or beverage, including any alternatives of milk products, almond milk, rice milk, soy milk, etc. It can be used in a variety of...

Embodiment 1

[0335] Example 1: Growth of Fusarium strains MK7 and other fungi in a static disc reactor.

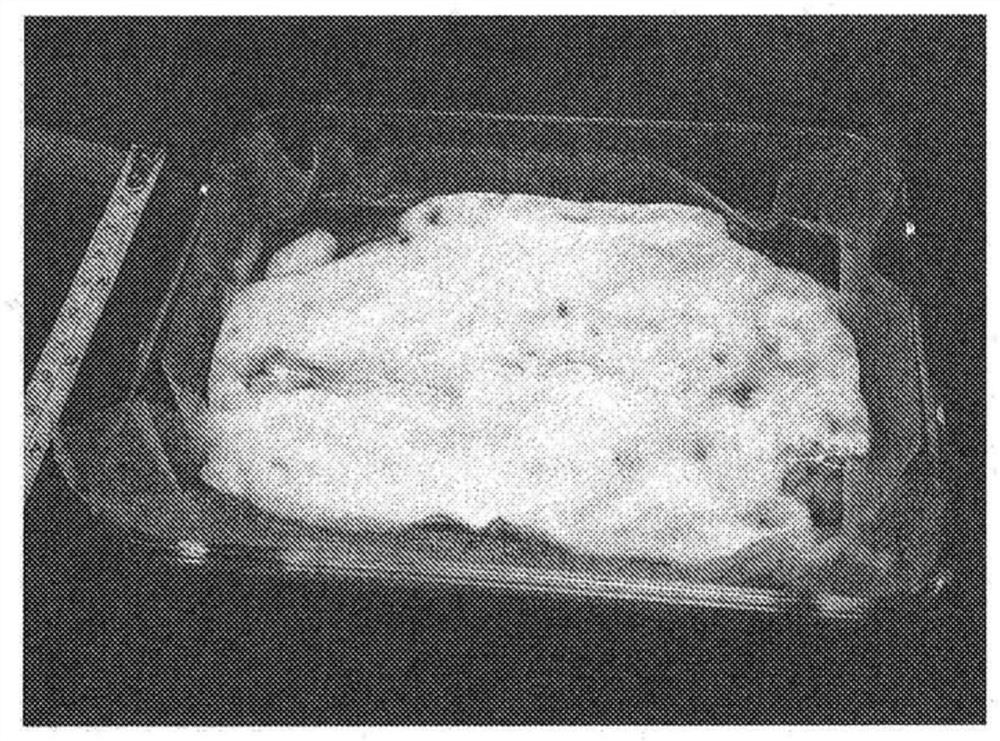

[0336] The shallow static tray reactor described in PCT / US2017 / 020050, cultured filamentous eosinophiliciostrum strain MK 7, Ganoderma lucidum (Ganoderma lucidum) figure 1 A), rough skin ears (pearl oyster mushroom, figure 1 B: and blue oysters, figure 1 C) Hydrococcus (cauliflower; figure 1 D), 榆 (榆; figure 1 E) Bull Make (Big Bethemat) figure 1 F) and the Fusarium venenatum biosphere.

Embodiment 2

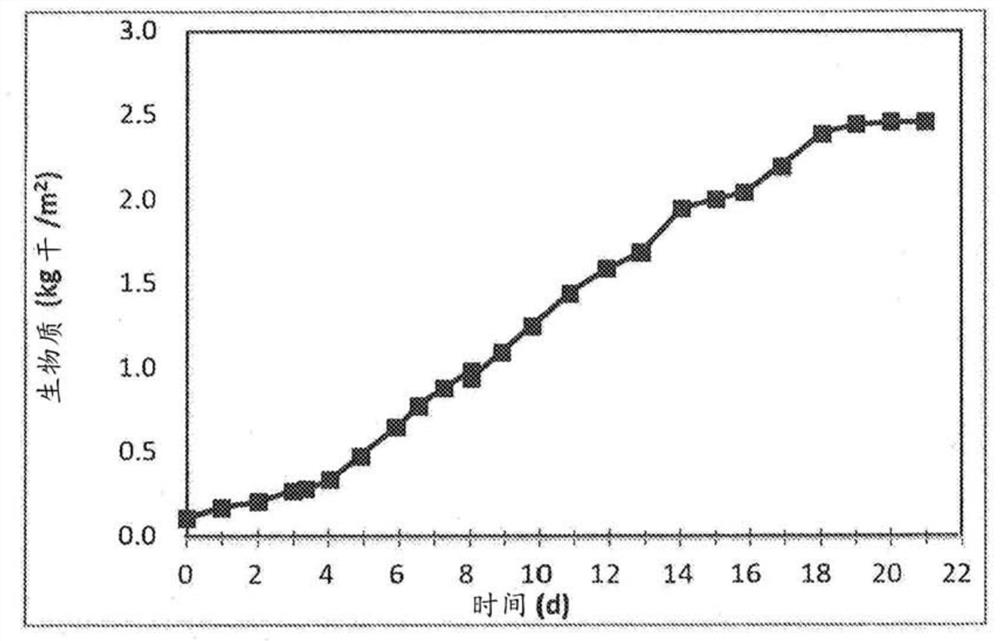

[0337] Example 2: Fusarium strain MK7 bio pads were grown (semi-static conditions) on the daily replacement nutrient medium.

[0338] About 3 cm thick dense Fusarium strain MK7 biosphere was cultured in a daily nutrient medium in 21 days. Use in 12.7x17.8cm The glass tray contains 7.5% of the sterile MK7-1 liquid medium (described in PCT / US 2017 / 020050) in the glass tray (described in PCT / US 2017 / 020050). In order to start the experiment, as described previously in PCT / US 2017 / 020050, 200 ml of nutrient medium was inoculated with 5% (volume / volume) in the late stage of 5% (volume / volume). 200 ml of inoculated medium is added to each of the three sterile trays, the tray in a sterile crude nylon screen. The cultures were incubated at room temperature (about 22 ° C) to incubate 4 days to form an initial biosphere formed at the surface of the liquid surface. After 4 days, the bio pad was gently raised from the tray using a nylon screen screen and tilt at a 45 degree angle t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com