Crop straw processing equipment for poultry feed

A technology of crop straw and processing equipment, which is applied in cutting equipment, application, agriculture, etc., and can solve the problems of inconvenient consumption by livestock and inconvenient packing of straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

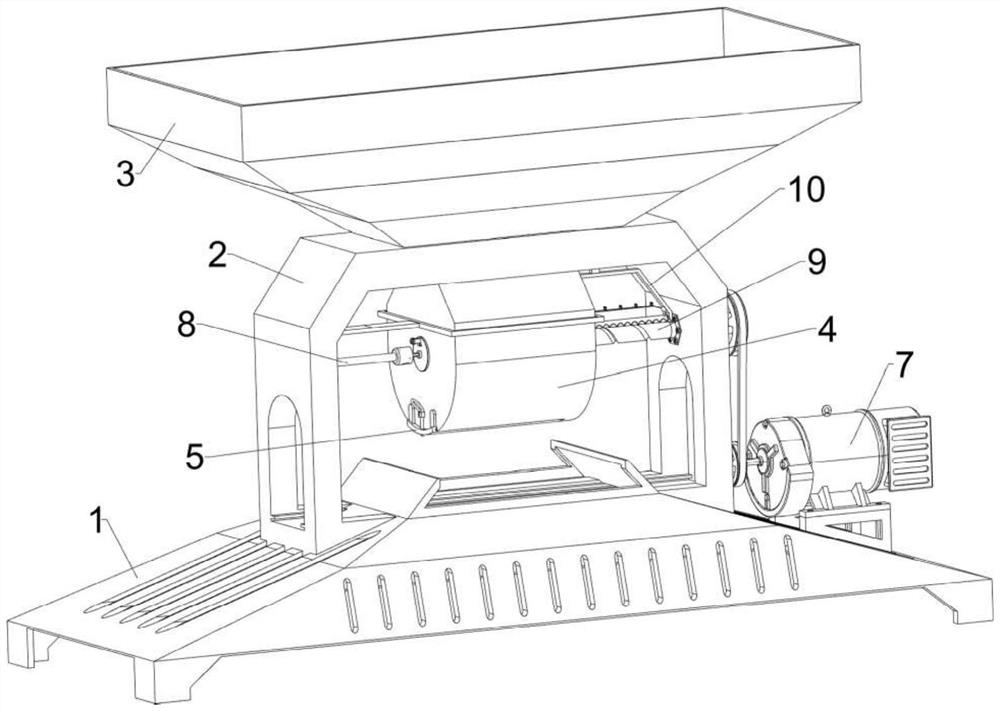

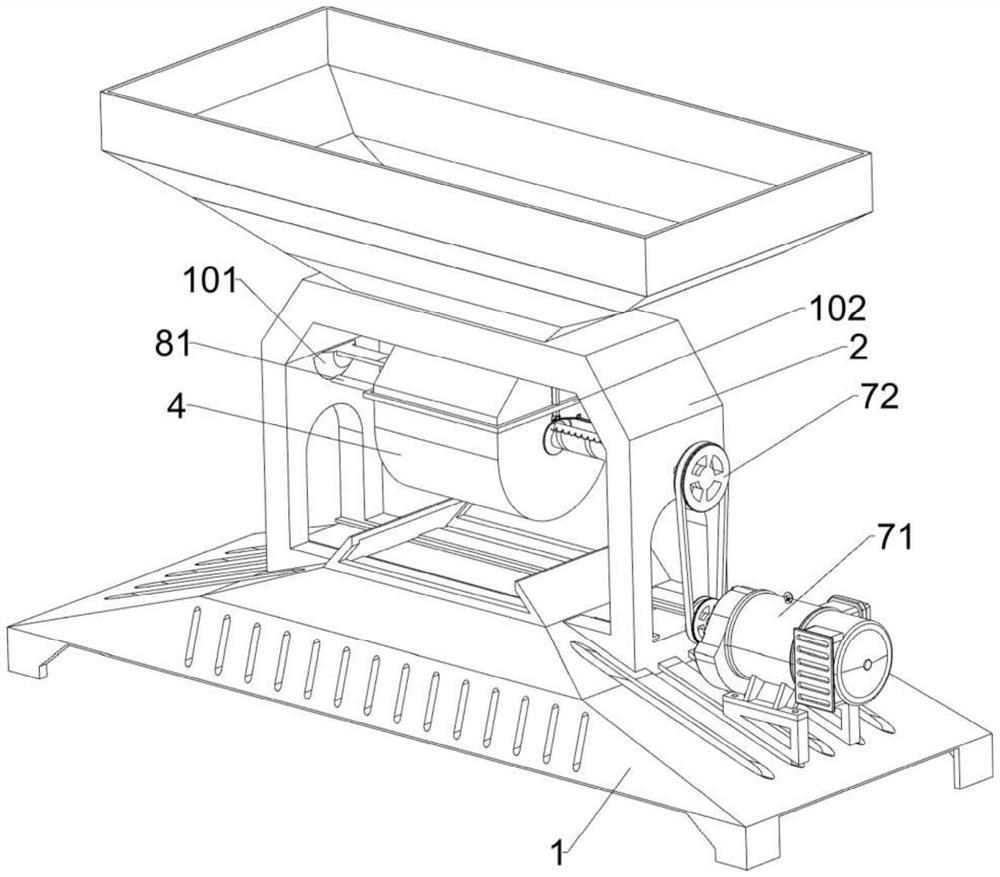

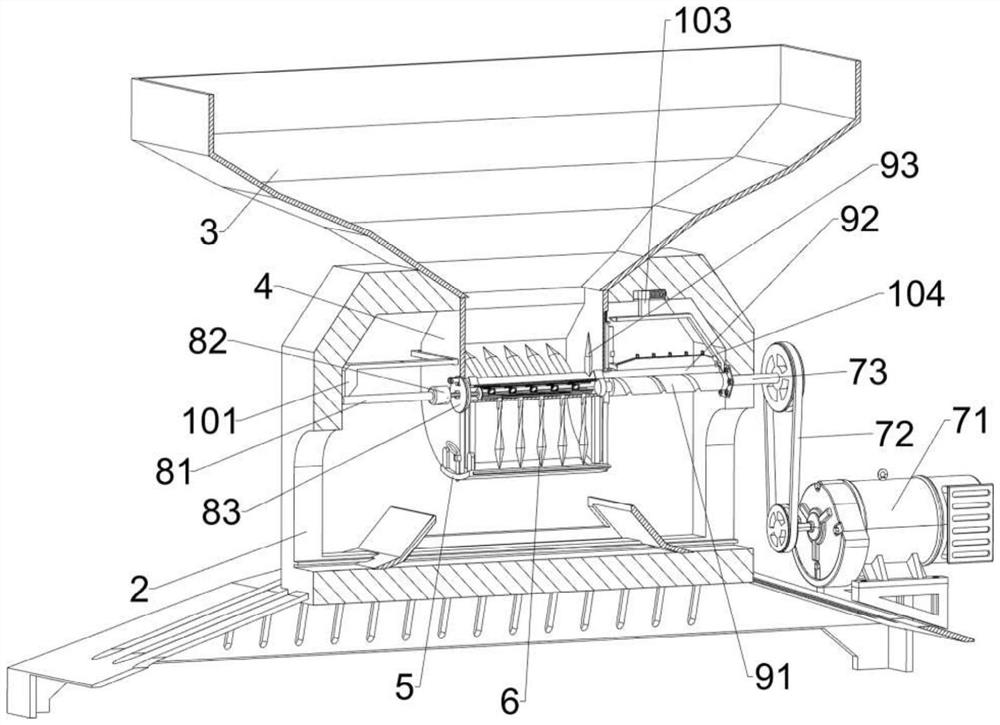

[0039] A crop straw processing equipment for poultry feed, including a base 1, an n-shaped seat 2, a lower hopper 3, a charging frame 4, an arc-shaped baffle 5, a cutter 6, a driving mechanism 7 and an auxiliary mechanism 8, please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Figure 8 , Figure 9 , Figure 11 and Figure 12 As shown, an n-type seat 2 is installed in the middle of the top of the base 1 by welding, and a lower hopper 3 is installed in the middle of the outer top of the n-type seat 2 by welding. The operator can put the straw into the lower hopper 3, n A charging frame 4 is fixedly connected in the middle of the inner top of the mold seat 2. The top of the charging frame 4 is fixedly connected and communicated with the bottom of the lower hopper 3. The bottom of the charging frame 4 is open, and the front and rear sides of the opening of the charging frame 4 are There are arc-shaped baffles 5 slidingly connected between them, an auxi...

Embodiment 2

[0046] On the basis of Embodiment 1, it also includes a material cutting mechanism 9, and the material cutting mechanism 9 includes an outer spiral cylinder 91, a triangular sliding plate 92, a blade 93, an n-shaped frame 94, a movable rod 95, an arc block 96, the first A spring 97, a second spring 98 and a third spring 99, see figure 1 , image 3 , Figure 4 , Figure 8 , Figure 10 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, a triangular sliding plate 92 is slidably connected between the upper parts of the turntables 83 on the left and right sides, the bottom of the triangular sliding plate 92 is in contact with the outer top of the cylinder 84, and the middle of the top of the triangular sliding plate 92 is slidably connected with a blade 93. When the blade 93 moves left and right, the blade 93 can cut off the stalks. The second spring 98 is symmetrically fixed between the inner bottom of the blade 93 and the inner top of the triangu...

Embodiment 3

[0051] On the basis of Embodiment 1 and Embodiment 3, it also includes a guide sleeve 11, a limit rod 12 and a pull ring 14, please refer to Figure 4 and Figure 5 As shown, there is a through hole 13 in the middle of the left part of the arc-shaped baffle plate 5, and a guide sleeve 11 is installed in the middle of the lower part of the outer left side of the charging frame 4 by welding. 12. The bottom end of the limit rod 12 runs through the through hole 13. The limit rod 12 can limit the position of the arc-shaped baffle 5. The top of the limit rod 12 is connected with a pull ring 14 by welding. When the operator pulls the When the ring 14 moves upward, the pull ring 14 can drive the limit rod 12 to move upward.

[0052] Also include fixed frame 15, scraper 16 and the fifth spring 17, please refer to Figure 4 , Figure 5 , Figure 14 , Figure 15 and Figure 16 As shown, the outer bottom of cylinder body 84 is left and right symmetrically installed with a fixed fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com